Martin,

that is a very-nearly..........

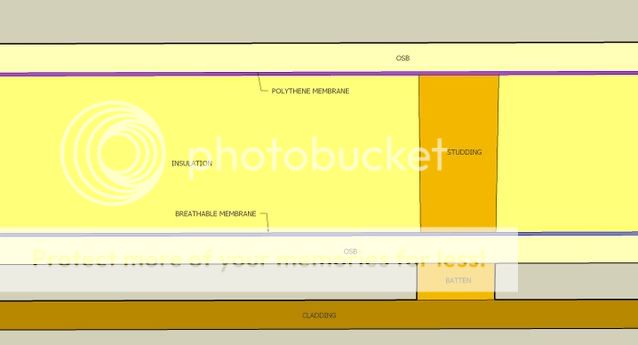

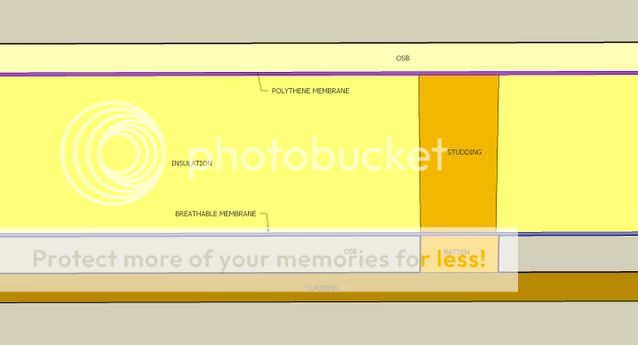

........the problem with it is the OSB, which is virtually vapour-impermeable due to the high levels of glue. Your breathable membrane won't be doing anything much at all, because no moisture will get past the OSB.

In a workshop, I would replace the plasterboard with the OSB, solving 2 problems in one go. The OSB is a good surface for a workshop, being more robust than plasterboard (and you can fasten stuff directly to it), and it obviously does the sheathing (racking resistance) job wherever it is in the the wall structure. Being on the inside of the wall its vapour-resistant properties are exploited exactly where they should be. My only caution with OSB is to be sure to maintain gaps around the edge of all sheets, because it really does bow if not given room to move.

Having moved the OSB to the inner face, your breathable membrane is doing its job properly, and is also holding the insulation up.

The airgap behind the cladding is exactly right. Just a tip if you haven't done it before (excuse sucking eggs lesson if you have!) .......use 2 inch counterbattens so that you can get a decent amount of each board onto a batten if you need to butt-join two boards. Stagger vertical joints for a really first rate job......and stain your boards before you nail them in place, as they will shrink and expose bare wood otherwise. One nail per board per batten........30mm up from the bottom if you have 25mm overlap.

Look how much money I've saved you.......all that plasterboard!!

I look forward to the pictures!

Mike