Ok. So here is my update that a few of you asked for regarding the insulation foam available from B&Q for ~ £5 for a 600 * 1200 * 52mm

I have posted a few pictures.

I cut the boards in half and ripped then down on the saw so they were 450 * 600mm. After I cut them on the table saw I marked the outline of the curve using the template. I did not try routing the foam as I was going to finish the shaping via another method.

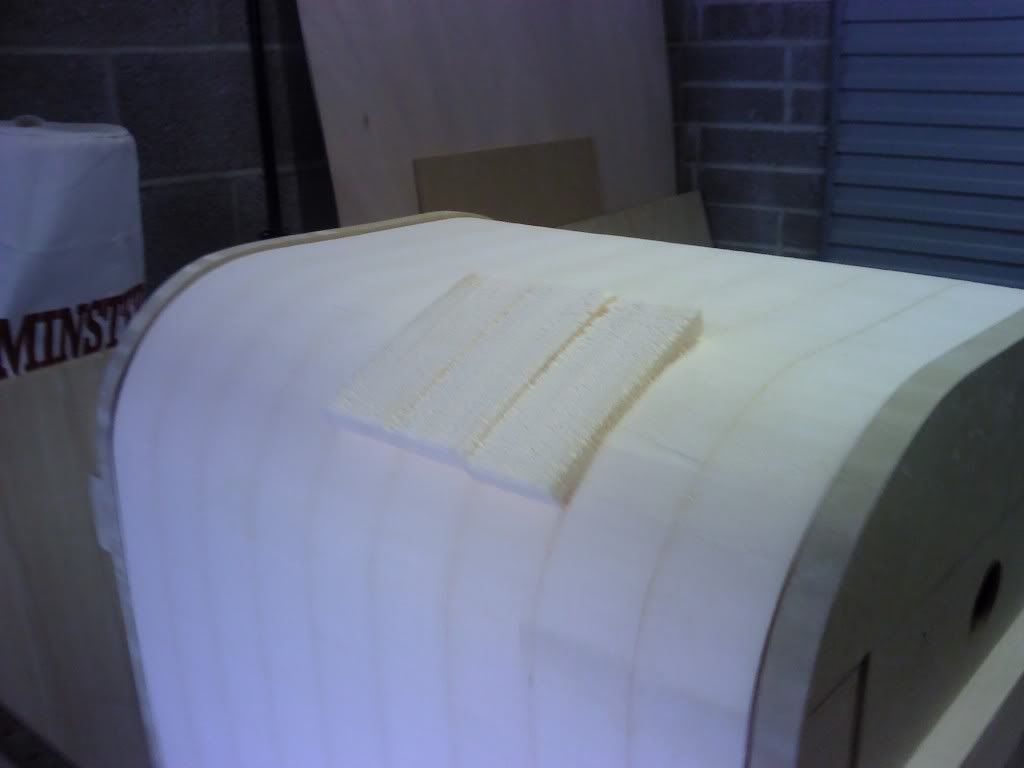

After rough cutting the corners with a jigsaw, I sandwhiched all of the pieces together between 2 of the original 18mm mdf ribs that did not get damaged when the mdf former collapsed.

Having sandwhiched them together I then used my orbital sander and a long piece of 2"*2" timber with a piece of 60 grit sand paper stuck to the underside. This was then used to final shape the form.

I made a slight mistake on one of the rounded ends, but it was a simple case of sanding flat and bonding a couple of piece in. I glued all of the pieces using polyurethane glue, which worked a treat.

The next picture, shows the finished form, which I covered in masking tape so as to protect it should any glue leak onto it.

I then stuck it all in the vac bag for a dry test. It worked a treat and the foam did not collapse in the slightest.