I wanted to create a worktop from a number of glued boards, so purchased some PAR pine (44mm x 95mm). The piece would be 1.6m long, and made from 6 boards glued up. Having recieved the timber, it looked pretty straight, and there wasn't much cupping when I placed a straight edge against it's width. I then left it a week in my garage for it to settle with humidity (not sure if this was required as it only came from down the road  ).

).

After that week I came back to start work on it, I checked the wood again and it was still about the same as before in terms of squareness. Laying the pieces freely on a flat surface, I noticed there were large gaps along the length between boards (about 4mm in some cases), but they all came out with enough clamping pressure. After the glue up, I unclamped everything and was happy with the results, the piece as a whole was pretty flat, it wobbled a bit, but not much. As some boards were slightly thicker than others, there were steps, so then set about going over it with a belt sander to bring it all to the same thickness. At this point, I was happy with what I had, but unfortunately, it would be 6 weeks before I came back to this project and in that time it was left on a flat surface in the garage.

Having come back to it six weeks later, it's a mess ... Every board has cupped along the width, and the thing as a whole is all wonky. If I lay it on a flat surface, I can just about get my finger under it!!!!

... Every board has cupped along the width, and the thing as a whole is all wonky. If I lay it on a flat surface, I can just about get my finger under it!!!!

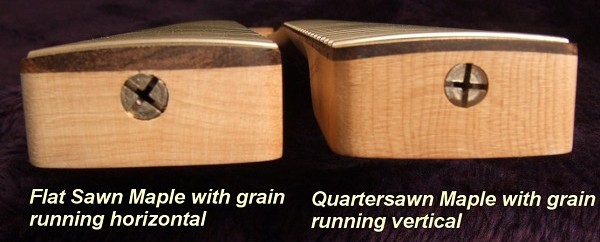

It looks like this.

What did I do wrong? If I hadn't of taken the six week break, I would have finsihed it and installed it thinking it was all ok only to find this six weeks later

I don't know what I'll do with what I have, can it be saved?

After that week I came back to start work on it, I checked the wood again and it was still about the same as before in terms of squareness. Laying the pieces freely on a flat surface, I noticed there were large gaps along the length between boards (about 4mm in some cases), but they all came out with enough clamping pressure. After the glue up, I unclamped everything and was happy with the results, the piece as a whole was pretty flat, it wobbled a bit, but not much. As some boards were slightly thicker than others, there were steps, so then set about going over it with a belt sander to bring it all to the same thickness. At this point, I was happy with what I had, but unfortunately, it would be 6 weeks before I came back to this project and in that time it was left on a flat surface in the garage.

Having come back to it six weeks later, it's a mess

It looks like this.

What did I do wrong? If I hadn't of taken the six week break, I would have finsihed it and installed it thinking it was all ok only to find this six weeks later

I don't know what I'll do with what I have, can it be saved?