Thank you beech1948 for your comprehensive reply.

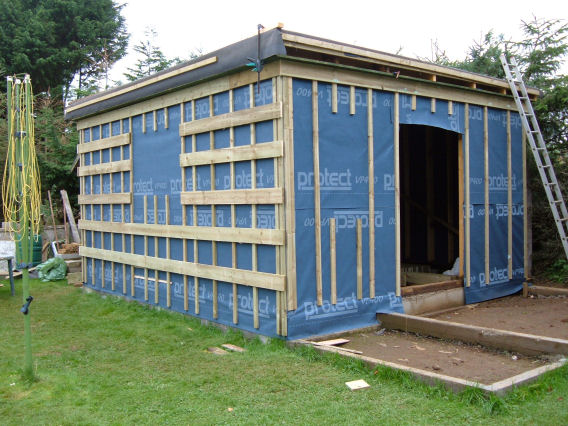

Just to be sure can I just mention that I have a large shed 18' x 15' which has been in situ for 5 years or so and in good condition.

I now want to insulate it. It does not leak.

The key features are that the construction is of 10mm thick shiplap X 120mm wide - again all in very good condition.

The stud frame is 70mm deep by 35mm wide. The gaps between the uprights is 560mm in the main.

I was thinking of buying the thermal insulation & noise reduction, currently on offer £26.69 a pack which covers 7.2m2 from Wickes suggested by giantbeat.

However that is 50mm thick so arguably there would be a gap of 20mm. Should I go for 75mm thick and will it 'stand up' between the uprights.

How should I attach the insulation to the inside of the shiplap?