jimi43

Established Member

I've been on the slopes again....

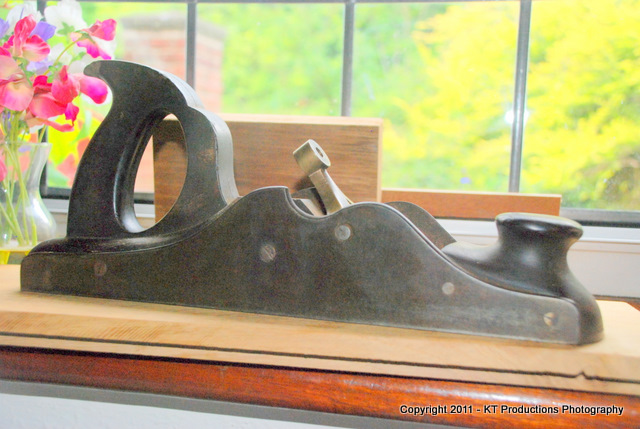

Let me introduce you to Alexander....

Following along from my traditions of naming my little infills...this one is named in honour of one of the finest master planemakers of the infill generation...Alexander Mathieson (Glasgow and Edinburgh).

Also my wont....is to get basket cases for a tad less than market value and sort them out...I hate to see a fine piece of history disappear in a pile of rust!

I seem to be plagued with missing lever cap bolts...here we go again!

And remember that little Robert Sorby saw with the nick out of the handle...

...yup...you guessed it...same old problem! Well...at lest this time I've had some practice!

The iron is missing...so that means another visit to the kiln...I might hit this one with a 4mm 01 job...it's a bit meatier this old boy...being 13" 1/2" from tip to elbow...a panel plane.

It would appear to have a very strange old split down the infills...both of them as you can see from the shot above! I think this was made in two halves...or at least the stock was doubled up before being cut up...this would explain the deviation at the bun....

It has the frequently encountered, heart and shield lever cap design...which I have seen often...but not in this configuration. Thankfully it has not cracked!

The sole and mouth are the best bits...and the most important...they are near as damn, perfect! I have tried another iron in this already and it whizzes along...leading me to believe I shall be leaving the sole alone....something I would prefer to do to preserve the patina where possible.

So....another family picture is on the way...we are getting there slowly...but I have a feeling this one will take the place of my No. 5 1/2 in the not to distant future!

More later when I get some shavings going!

Jim

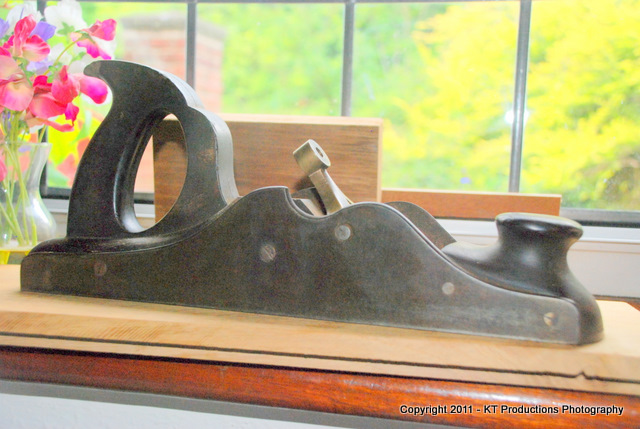

Let me introduce you to Alexander....

Following along from my traditions of naming my little infills...this one is named in honour of one of the finest master planemakers of the infill generation...Alexander Mathieson (Glasgow and Edinburgh).

Also my wont....is to get basket cases for a tad less than market value and sort them out...I hate to see a fine piece of history disappear in a pile of rust!

I seem to be plagued with missing lever cap bolts...here we go again!

And remember that little Robert Sorby saw with the nick out of the handle...

...yup...you guessed it...same old problem! Well...at lest this time I've had some practice!

The iron is missing...so that means another visit to the kiln...I might hit this one with a 4mm 01 job...it's a bit meatier this old boy...being 13" 1/2" from tip to elbow...a panel plane.

It would appear to have a very strange old split down the infills...both of them as you can see from the shot above! I think this was made in two halves...or at least the stock was doubled up before being cut up...this would explain the deviation at the bun....

It has the frequently encountered, heart and shield lever cap design...which I have seen often...but not in this configuration. Thankfully it has not cracked!

The sole and mouth are the best bits...and the most important...they are near as damn, perfect! I have tried another iron in this already and it whizzes along...leading me to believe I shall be leaving the sole alone....something I would prefer to do to preserve the patina where possible.

So....another family picture is on the way...we are getting there slowly...but I have a feeling this one will take the place of my No. 5 1/2 in the not to distant future!

More later when I get some shavings going!

Jim