RussianRouter

Established Member

Just waiting for the plate to be fitted and then I'll tackle the guide fence.

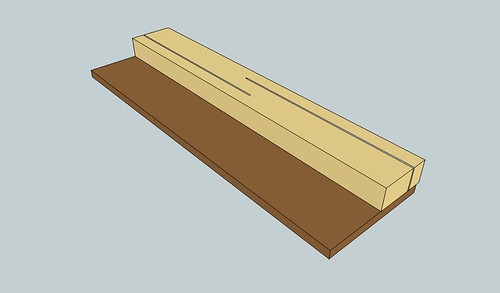

This is the workpiece clamp in place...

[/img]

[/img]

This is the workpiece clamp in place...

aesmith":twiiov48 said:What are you using for the table top? Is that a few layers of MDF glued together, or something more high-tech?

Chems":nbkxbes1 said:When you say workpiece clamp, do you mean your going to trap the work between that and the fence?

Chems":193jpx9e said:To mirror your abruptness, as you won't find anything on the market similar that should tell you its a bad idea. And for someone who claims to be a router expert you should know that you shouldn't directly trap against the cutter in table mode. But I don't care, their your eyes and hands.

MickCheese":39wk6uul said:Just a reminder how powerful a 2000w router is!

barkwindjammer":1c3r21ix said:Yes, do a quick sketch

Enter your email address to join: