J_SAMa

Established Member

Bought a pre-war, NOS J. Jowett plane iron for a plane build (small jointer). For some reason it is surprisingly brittle. It develops chips quickly, really quickly. Below is a shot of the edge after less than a dozen strokes on pine. Sharpening angle was a good 35 deg. I even added a back bevel.

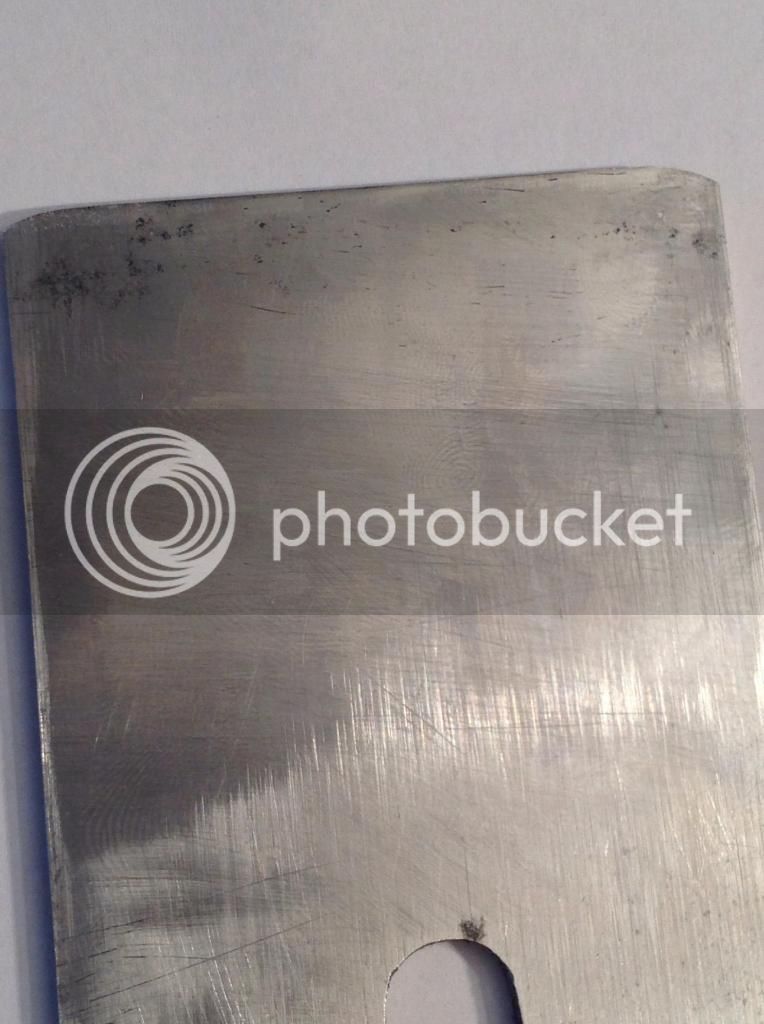

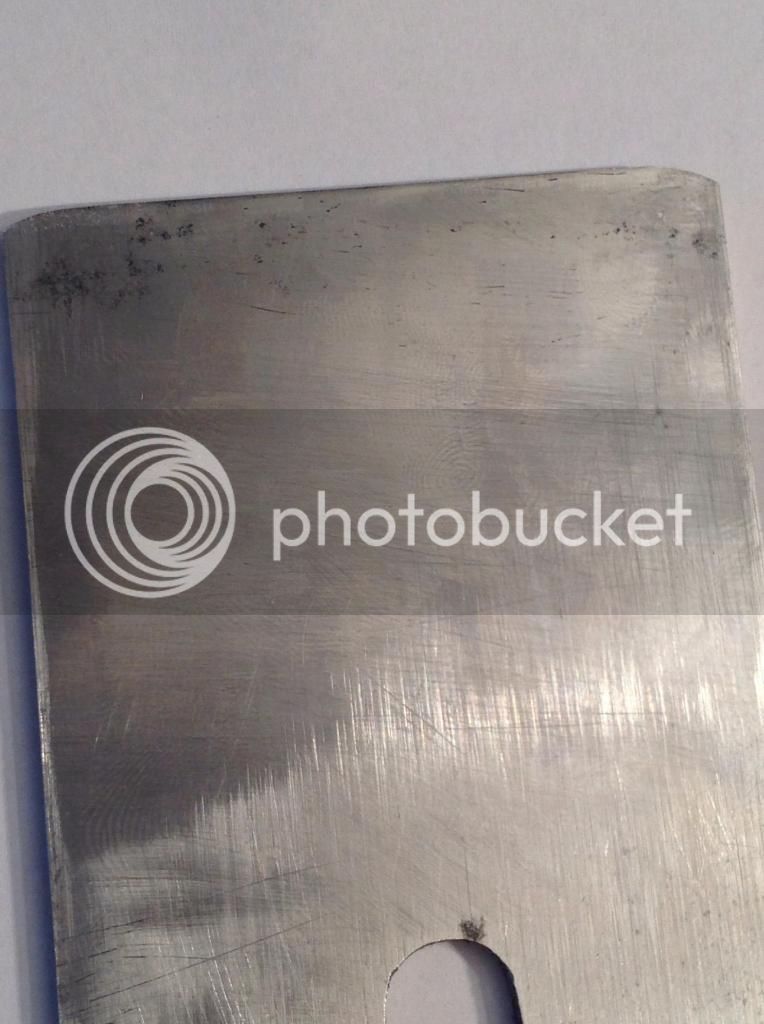

Here's the weird bit: whilst I was flattening its back on a diamond stone, little particles started to fall off... They were extremely hard, hard enough to scratch the stone by knocking diamond off. It's a bit hard to put into words so pics:

Those short black lines:

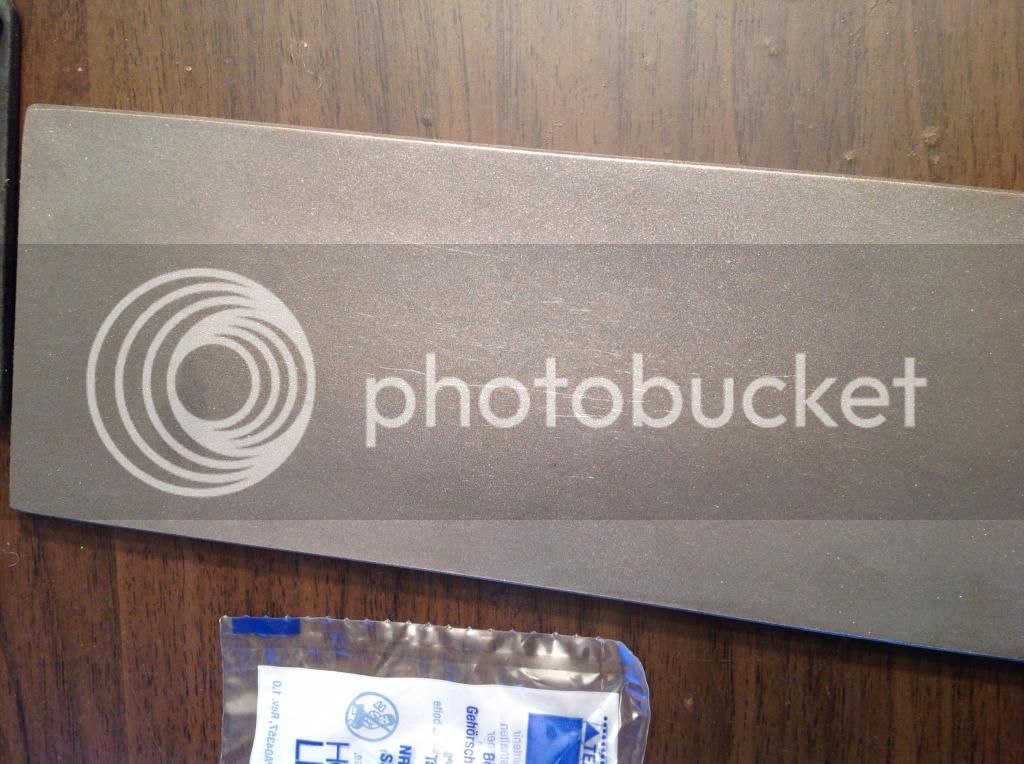

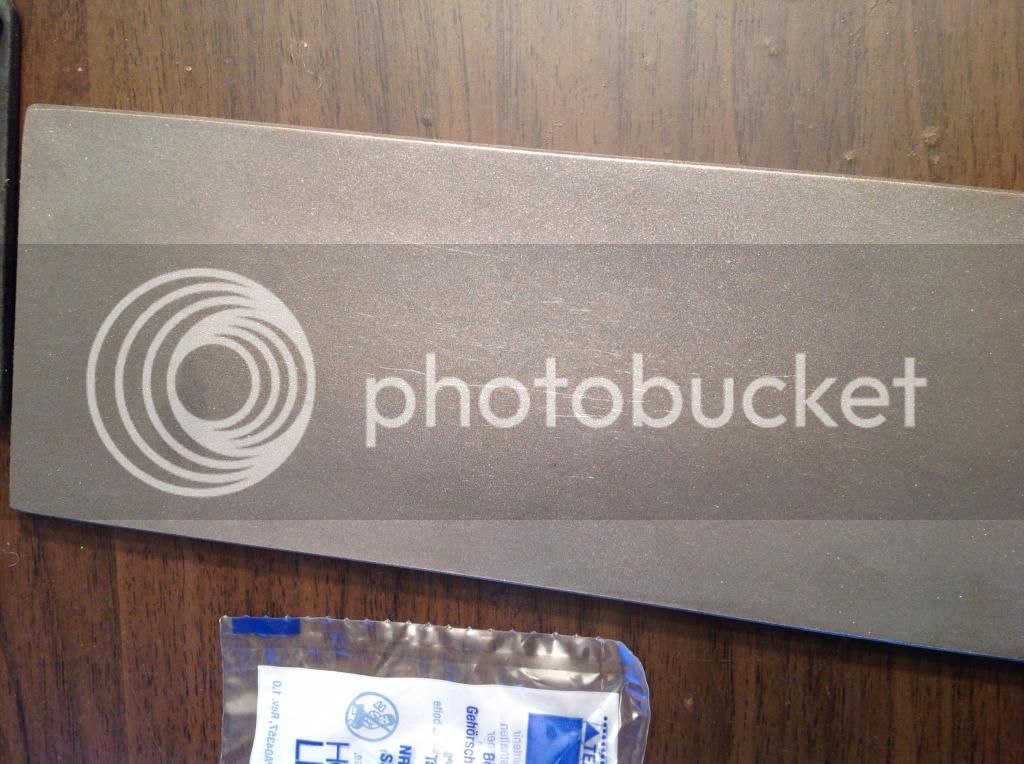

And they did a number on the stone too:

Going by the way it feels on the stone, I think that if anything, it is overly hard, not soft. But then again maybe I'm just used to how quickly the Bailey-type irons sharpen. The burr is tough to hone off, not very typical of old steel at all. With my other old irons the burrs just jump off if I so much as point them at a strop.

Any ideas? Improperly tempered or wrong alloy content? If the former, should I pop it in the oven? At what temperature?

Lesson learned, don't buy NOS... There's a reason they were never used #-o.

Thank you,

Sam

Here's the weird bit: whilst I was flattening its back on a diamond stone, little particles started to fall off... They were extremely hard, hard enough to scratch the stone by knocking diamond off. It's a bit hard to put into words so pics:

Those short black lines:

And they did a number on the stone too:

Going by the way it feels on the stone, I think that if anything, it is overly hard, not soft. But then again maybe I'm just used to how quickly the Bailey-type irons sharpen. The burr is tough to hone off, not very typical of old steel at all. With my other old irons the burrs just jump off if I so much as point them at a strop.

Any ideas? Improperly tempered or wrong alloy content? If the former, should I pop it in the oven? At what temperature?

Lesson learned, don't buy NOS... There's a reason they were never used #-o.

Thank you,

Sam