krismusic

Established Member

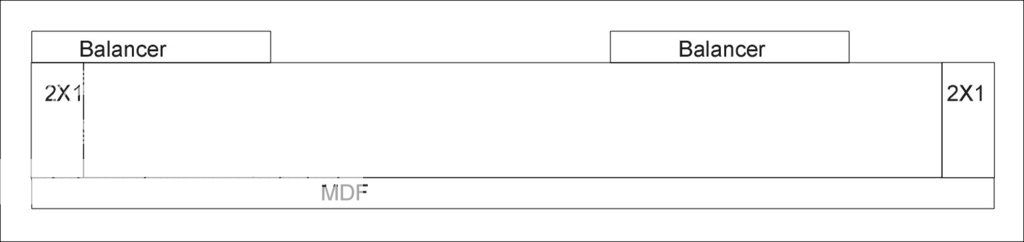

Hi guys. This is an ongoing problem that has reared it's head once again. From time to time, over the last 30 yrs I have had the job of knocking up quantities of panels for exhibition stands. 2x1 frames . Used to cover them in 6mm ply but now use fire resistant MDF, 6mm. The problem is that from time to time the panels bend once assembled. The nearest I can describe is that it is a similar effect to what happens if you do not use a balancer when using laminate. It doesn't happen every time and I thought I had solved the problem by not glueing the boards and relying on 40mm air staples. The batch I am producing currently has curved. Any ideas what may be causing this? Sorry for the long post.