Nigel Taylor

Established Member

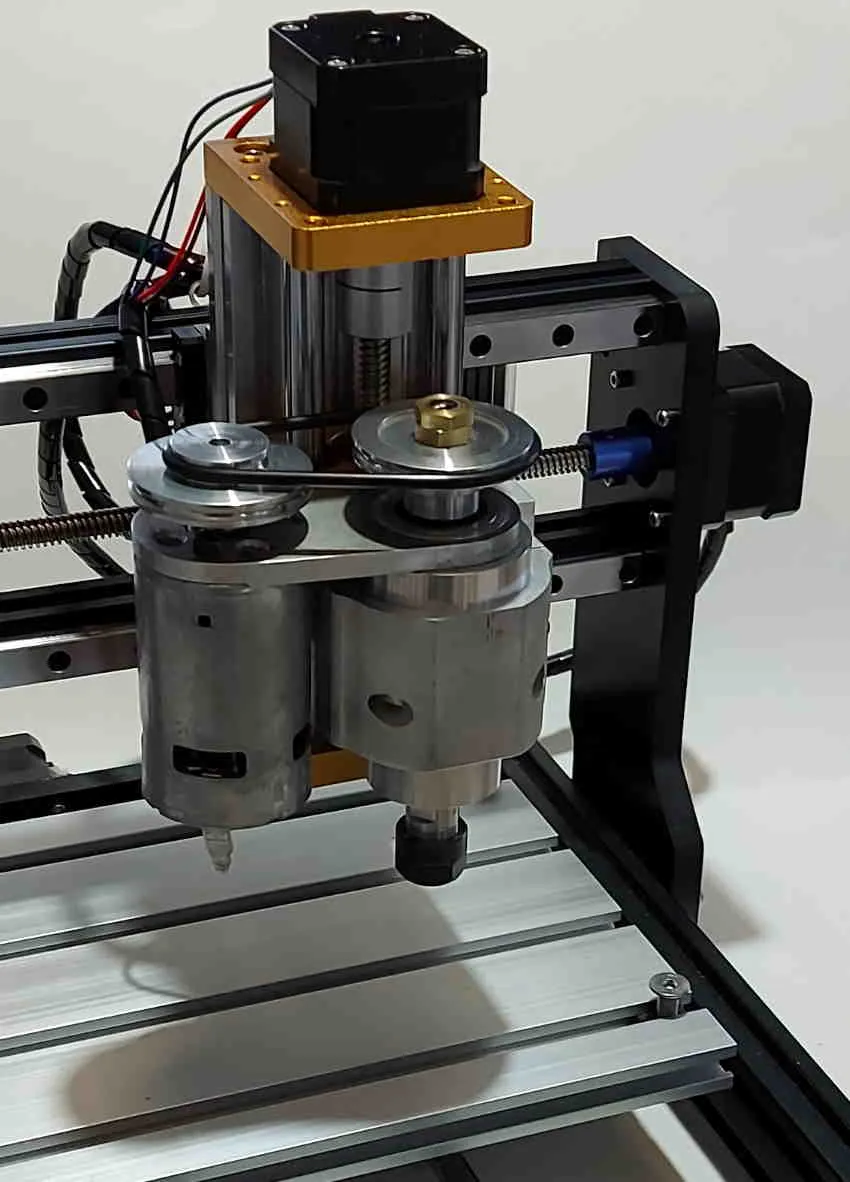

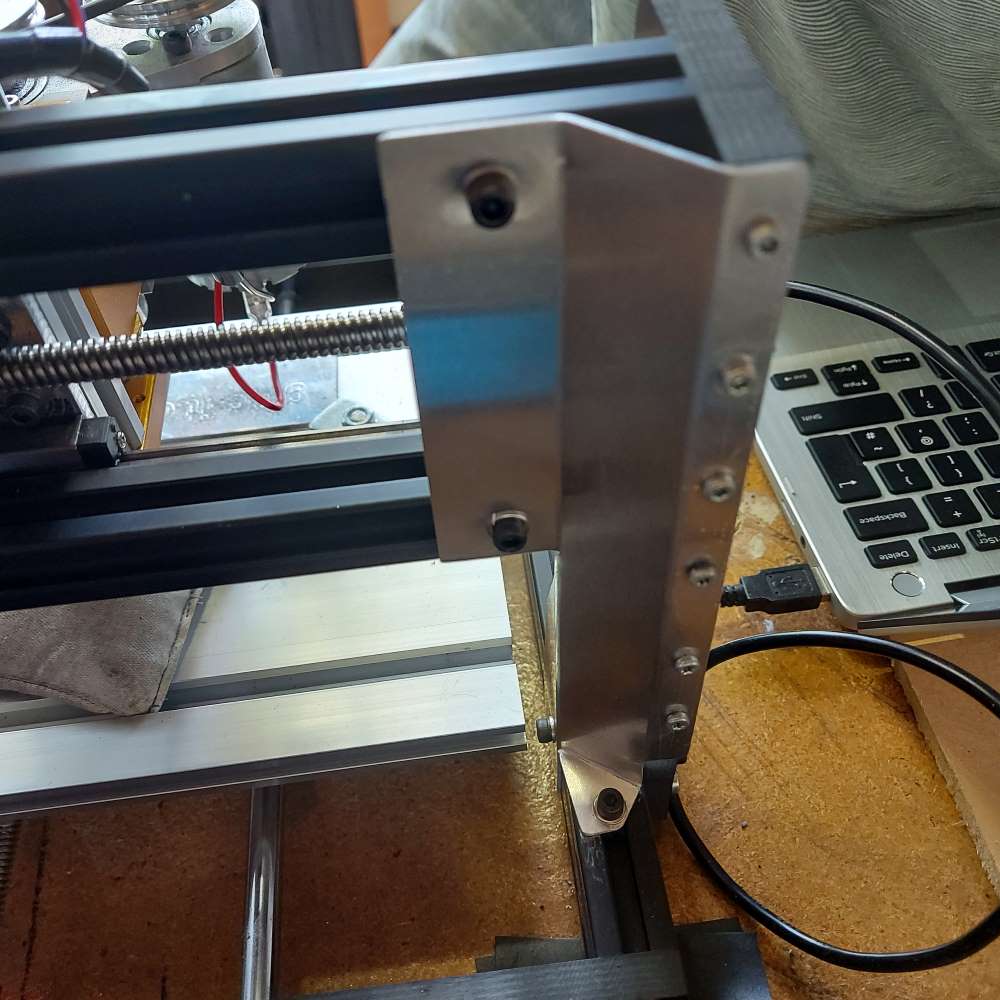

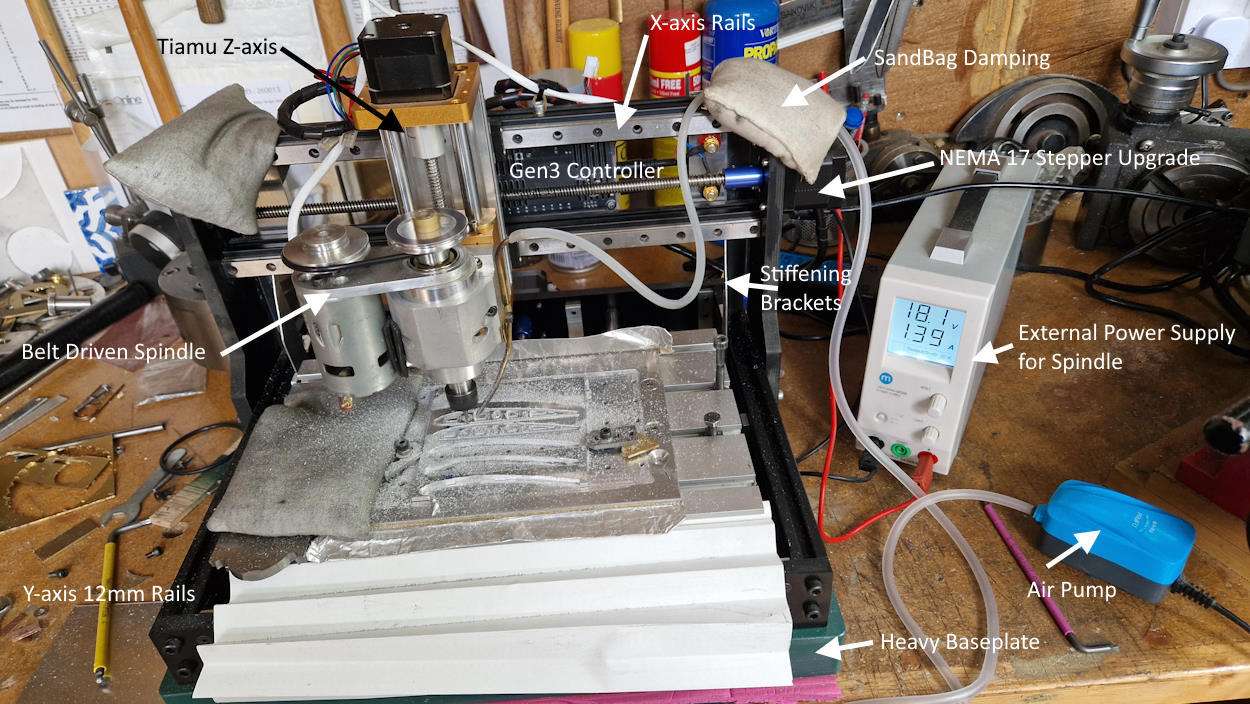

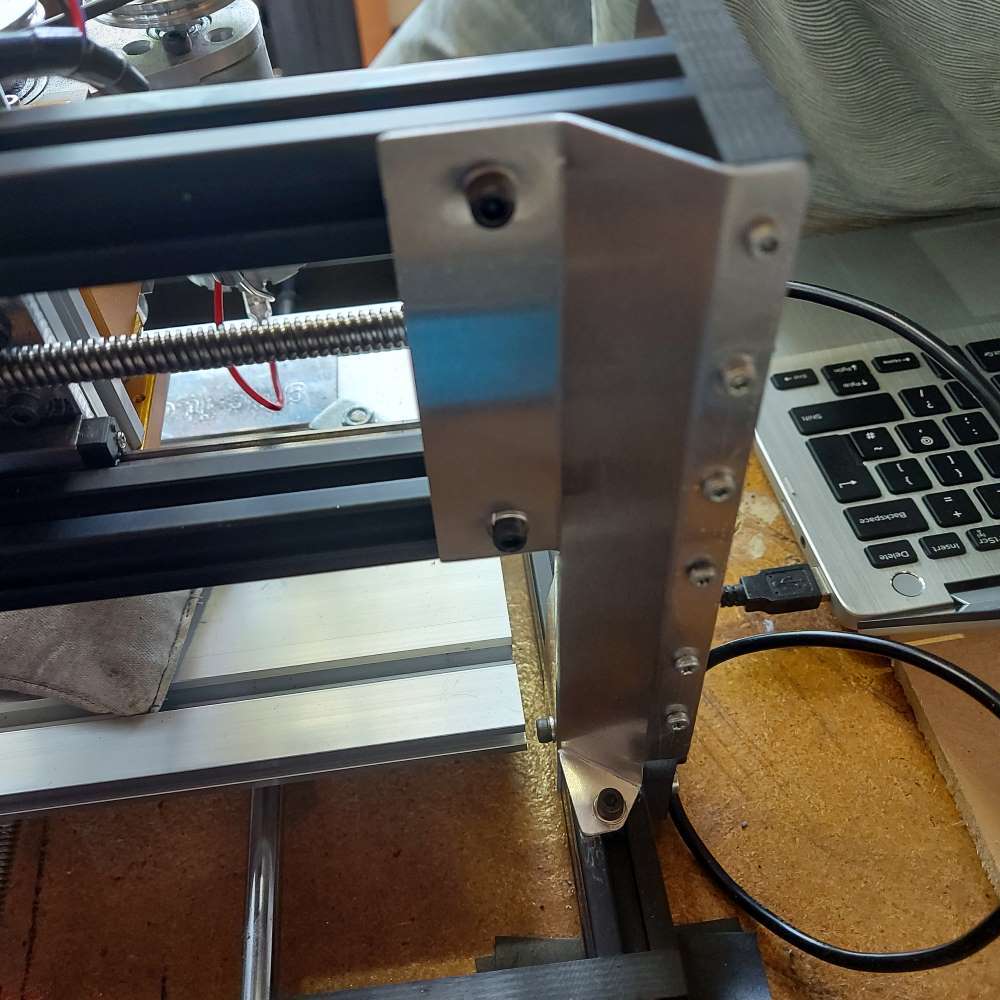

After changing the z-axis rails and increasing the stiffness of the x and y backlash I now have a Genmitsu 3018-pro that can accurately engrave hardwood.

OK, quite a few upgrades. But the lettering is 22mm high and 4mm deep, using a 1.3mm diameter end mill/burr.

OK, quite a few upgrades. But the lettering is 22mm high and 4mm deep, using a 1.3mm diameter end mill/burr.