After the router table the next piece of equipment to go mobile is the table saw.

Initial construction was 2 ply 18mm mdf for the top, with more 18mm for the sides, uprights, saw stand and base.

Built unit, added wheels, fitted saw and left overnight, come the morning there was a bit of a "sag", the saw was too heavy for the construction, don't think it was helped by the fact that I had mounted the castors outside of the main load. I made a torsion box and fixed it under the uinit, then added some extra bracing, it was better but still not quite there. Only one thing for it, add an extra set of castors in the middle of the unit. hey presto, solid as the proverbial rock with absolutely no sagging.

Next added a drop down outfeed table.

I thought that I'd need to add some fold down legs on the back edge of the outfeed table, but as it is with the 2 swing up braces it easily withstands the weight of a bag of cement.

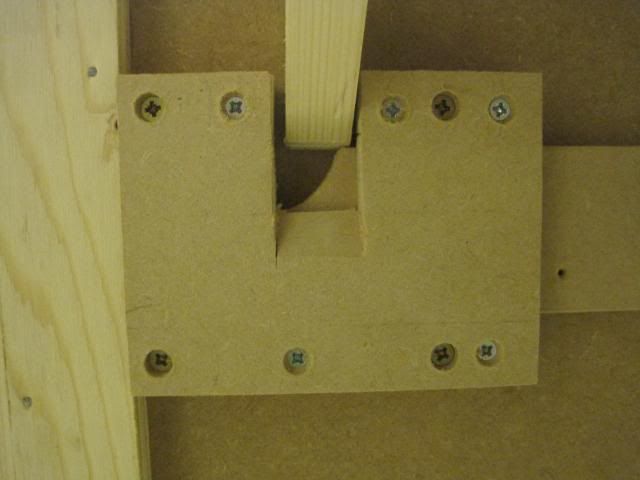

The braces are attached to the side of the unit (6mm nut and bolt) and swing up to locate in the catch.

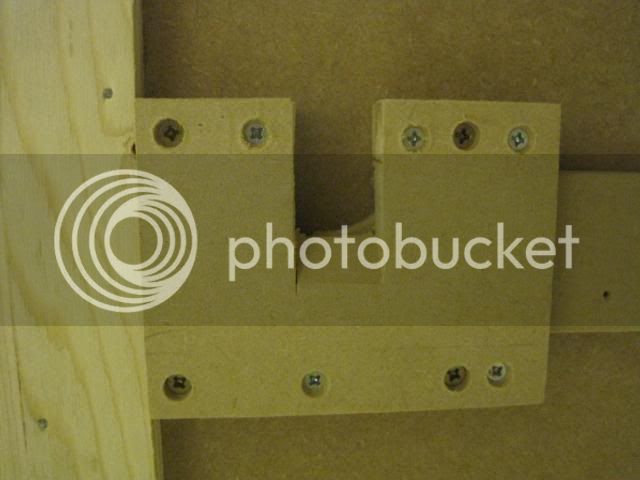

The catch in its "open" position, once the support is in place the slide is moved across, locking the support in place.

.

.

In its previous (fixed) workshop position the extraxtion for the crown guard was from overhead (rafters) now its mobile I don't have that optiuon so onto the whiteboard, eventually coming up with this:

The beam is easily removed if needed and the height is adjustable to cope with a higher of lower blade height.

Next thing on wheels is omething for the pillar drill, scms and new morticer - thats tomorrows job.

Cheers all

Vinny

Initial construction was 2 ply 18mm mdf for the top, with more 18mm for the sides, uprights, saw stand and base.

Built unit, added wheels, fitted saw and left overnight, come the morning there was a bit of a "sag", the saw was too heavy for the construction, don't think it was helped by the fact that I had mounted the castors outside of the main load. I made a torsion box and fixed it under the uinit, then added some extra bracing, it was better but still not quite there. Only one thing for it, add an extra set of castors in the middle of the unit. hey presto, solid as the proverbial rock with absolutely no sagging.

Next added a drop down outfeed table.

I thought that I'd need to add some fold down legs on the back edge of the outfeed table, but as it is with the 2 swing up braces it easily withstands the weight of a bag of cement.

The braces are attached to the side of the unit (6mm nut and bolt) and swing up to locate in the catch.

The catch in its "open" position, once the support is in place the slide is moved across, locking the support in place.

In its previous (fixed) workshop position the extraxtion for the crown guard was from overhead (rafters) now its mobile I don't have that optiuon so onto the whiteboard, eventually coming up with this:

The beam is easily removed if needed and the height is adjustable to cope with a higher of lower blade height.

Next thing on wheels is omething for the pillar drill, scms and new morticer - thats tomorrows job.

Cheers all

Vinny