RobertMP

Established Member

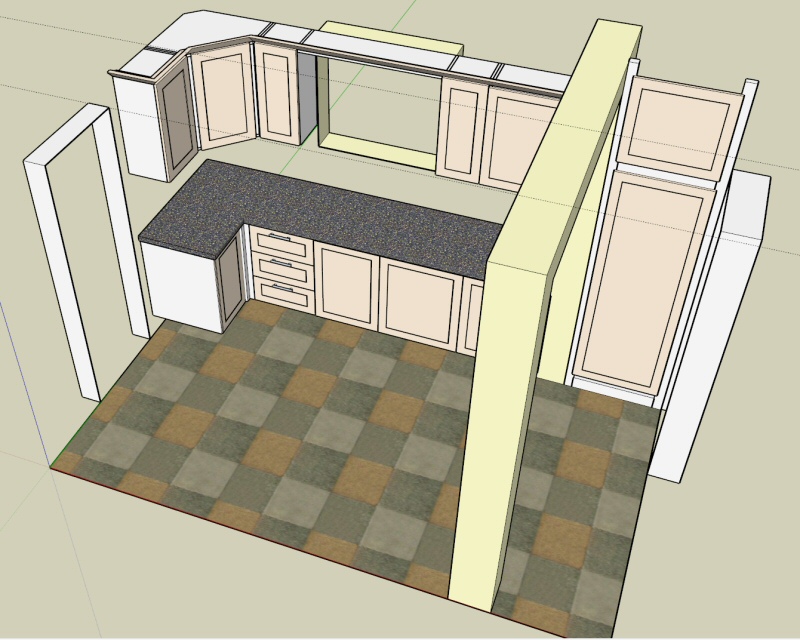

I wasn't going to start posting until after my upcoming holiday but as I've started cutting up the MR MDF and took a couple of pictures i thought i may as well start the thread off. I'm hoping logging my progress on here might spur me to get on with it as I seem to have developed a knack of leaving things until tomorrow

Anyway my take on board cutting...

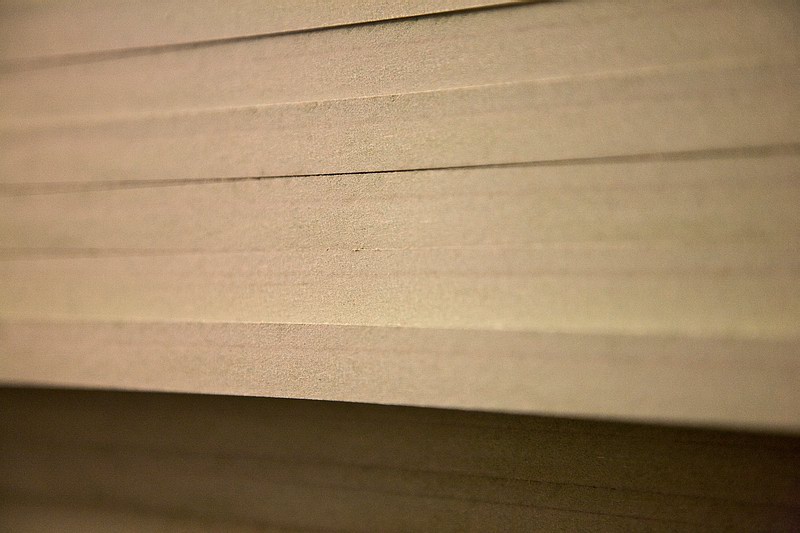

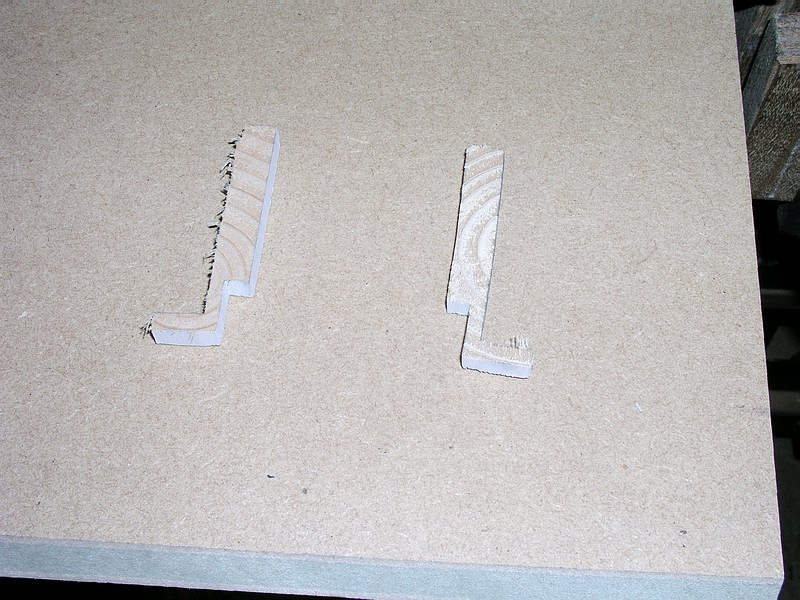

Need a lot of strips to stick round the edge of the doors to simulate panels so I cut a piece off of one 6mm sheet to use as a straight edge. Set my rule stop to allow for the blade offset on the saw and cut loads of 66mmstrips for my 60 mm finished edging. I cut the 2 sheets of 6mm together. The big vice is there to weigh the middle down so the board doesn't try to lift as i pass with the saw.

Then 2 sheets of 12mm got cut to 716 + 498 and a bit of clean up allowance. Very tight out of 1220mm width but it should be OK.

Lunch now

Anyway my take on board cutting...

Need a lot of strips to stick round the edge of the doors to simulate panels so I cut a piece off of one 6mm sheet to use as a straight edge. Set my rule stop to allow for the blade offset on the saw and cut loads of 66mmstrips for my 60 mm finished edging. I cut the 2 sheets of 6mm together. The big vice is there to weigh the middle down so the board doesn't try to lift as i pass with the saw.

Then 2 sheets of 12mm got cut to 716 + 498 and a bit of clean up allowance. Very tight out of 1220mm width but it should be OK.

Lunch now