DuncanDesigns

Established Member

So I decided I wanted to build some form of storage in the garage and what started out as a quick and inexpensive project, turned into a 12 month marathon which became an obsession after watching Jay Bates Mitre Station videos on YouTube. The garage had become a tip that had no order or layout. With my new found inspiration I hoped to kill two birds with the one stone.

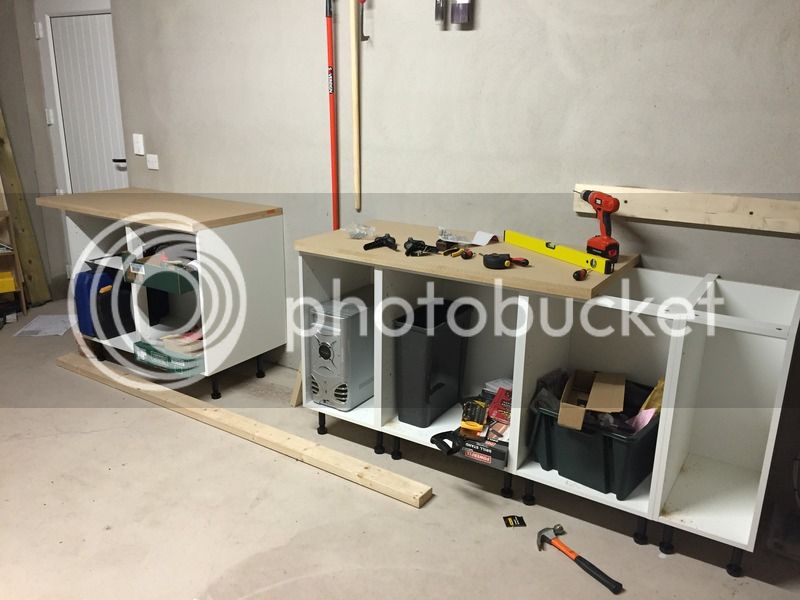

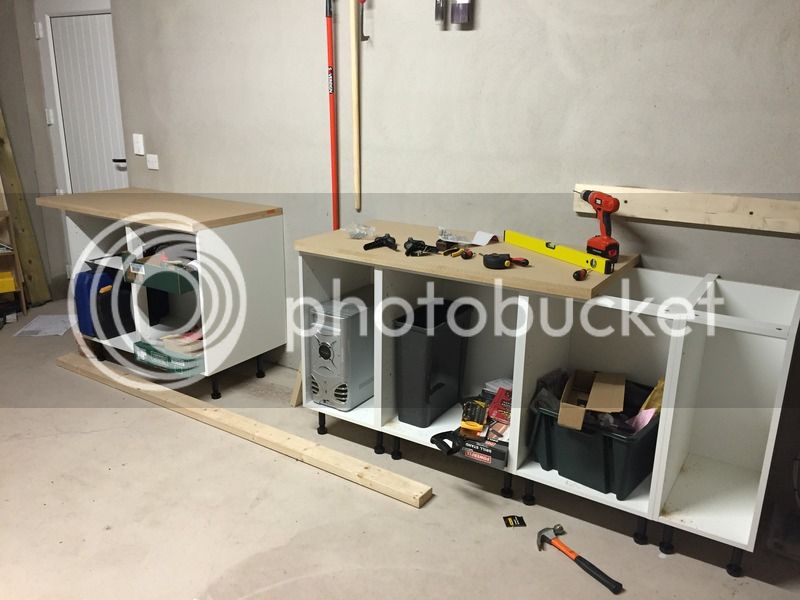

It started out with picking up these carcasses when a local B&Q were closing down. I had intended to build my own shells but when I saw these going for about £100 I decided it was too good an offer to pass up. I set them out and shifted them around until they were in a configuration I was happy with.

I decided I wanted to keep the overall look simple and straight forward so I used MDF for the worktop, doubling it up to make the depth required and then adding a 4mm MDF sheet to use as a waste board on the top surface. Under the mass of clutter it can just about be seen.

When everything was levelled up and placed where I was happy with, I started adding the worktops on each of the sections

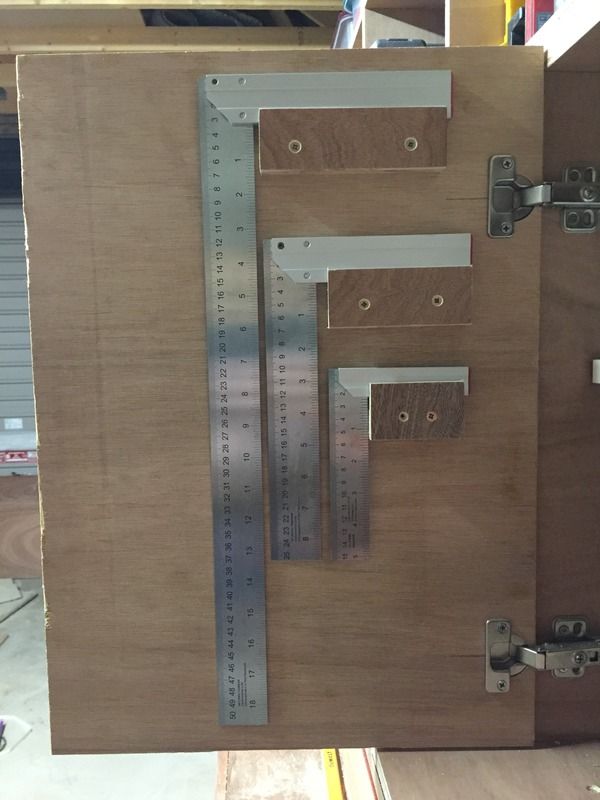

I added some edging and also bought a box of hinges to hang the doors - bargain of £17 on eBay for 20. I got a few sheets of 18mm Plywood cut to size to use as doors and drawer fronts. For now they are just set against the cupboards until I am ready to attach them to the hinges.

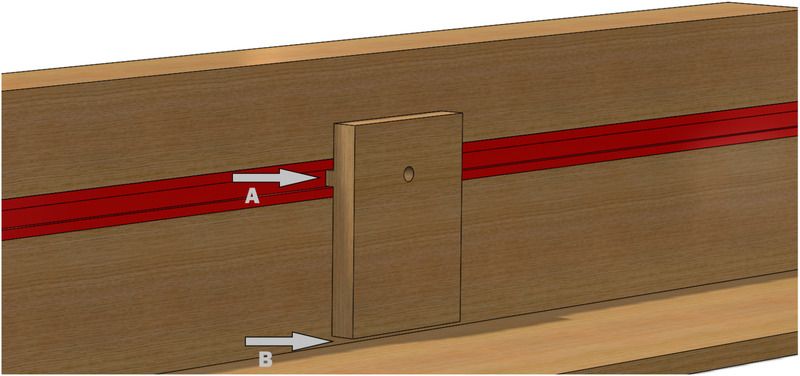

It was at this stage I decided I had to do some proper planning to work out exactly what I hoped to achieve. I drew a quick CAD model to work out some general sizes etc. I'm hoping to end up with something that resembles this when I'm done.

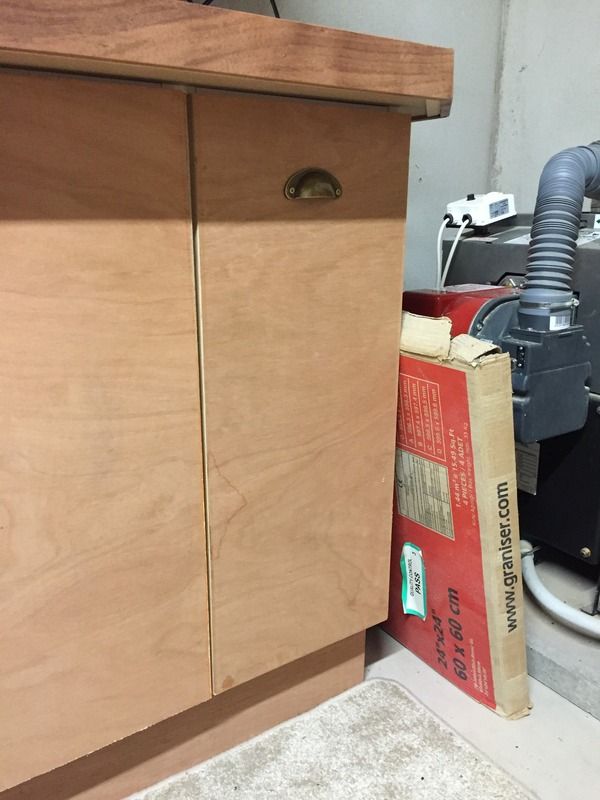

Then I started to add the doors

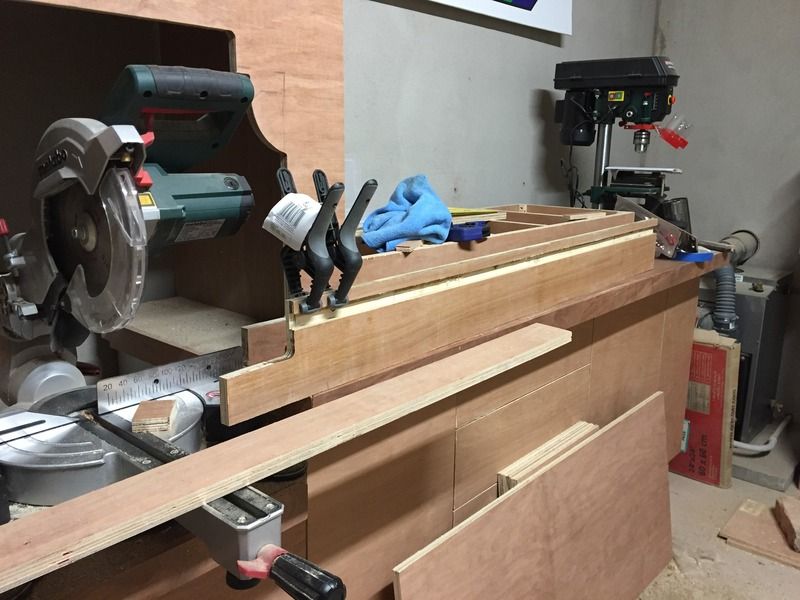

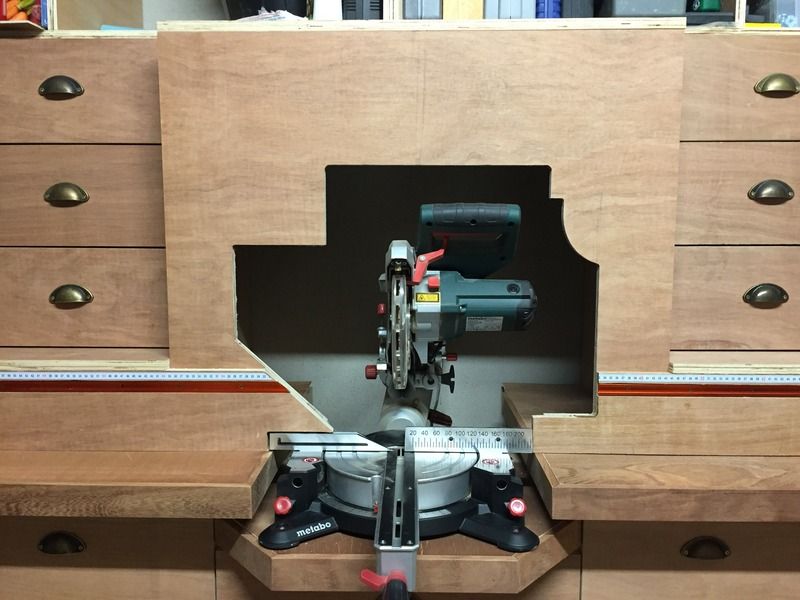

I then managed to pick up a small Mitre Saw at good value in the Christmas sale on ToolStop for £150. After measuring up the space and height requirements, a shelf was installed to hold it, and finished in the same style as the rest of the bench top.

Overall view so far

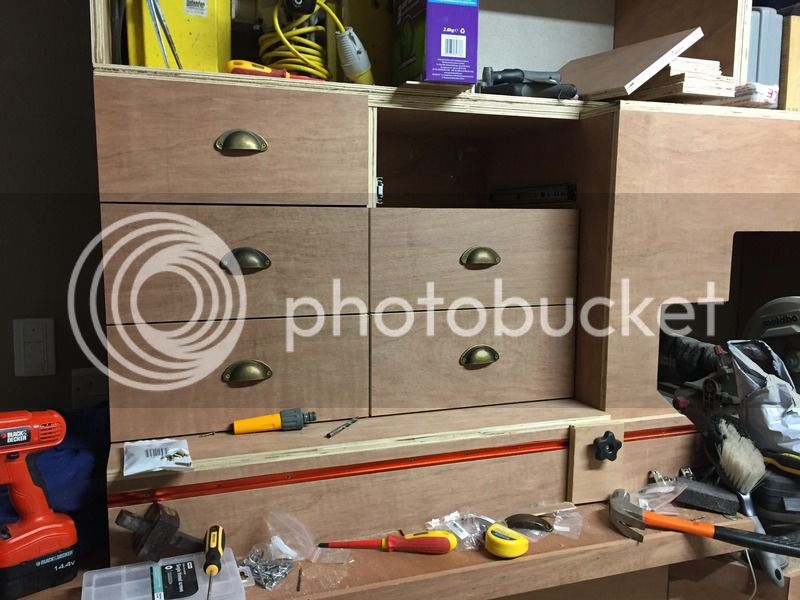

Next was time to make the drawers which will be set into the units. I'm not a wood worker and decided to do this project as a bit of fun/ learning but I have to say that this portion of the project nearly drove me to breaking point. This near killed me! If I don't have to make another drawer for several years i'll be very happy

It started out with picking up these carcasses when a local B&Q were closing down. I had intended to build my own shells but when I saw these going for about £100 I decided it was too good an offer to pass up. I set them out and shifted them around until they were in a configuration I was happy with.

I decided I wanted to keep the overall look simple and straight forward so I used MDF for the worktop, doubling it up to make the depth required and then adding a 4mm MDF sheet to use as a waste board on the top surface. Under the mass of clutter it can just about be seen.

When everything was levelled up and placed where I was happy with, I started adding the worktops on each of the sections

I added some edging and also bought a box of hinges to hang the doors - bargain of £17 on eBay for 20. I got a few sheets of 18mm Plywood cut to size to use as doors and drawer fronts. For now they are just set against the cupboards until I am ready to attach them to the hinges.

It was at this stage I decided I had to do some proper planning to work out exactly what I hoped to achieve. I drew a quick CAD model to work out some general sizes etc. I'm hoping to end up with something that resembles this when I'm done.

Then I started to add the doors

I then managed to pick up a small Mitre Saw at good value in the Christmas sale on ToolStop for £150. After measuring up the space and height requirements, a shelf was installed to hold it, and finished in the same style as the rest of the bench top.

Overall view so far

Next was time to make the drawers which will be set into the units. I'm not a wood worker and decided to do this project as a bit of fun/ learning but I have to say that this portion of the project nearly drove me to breaking point. This near killed me! If I don't have to make another drawer for several years i'll be very happy