noddy67

Established Member

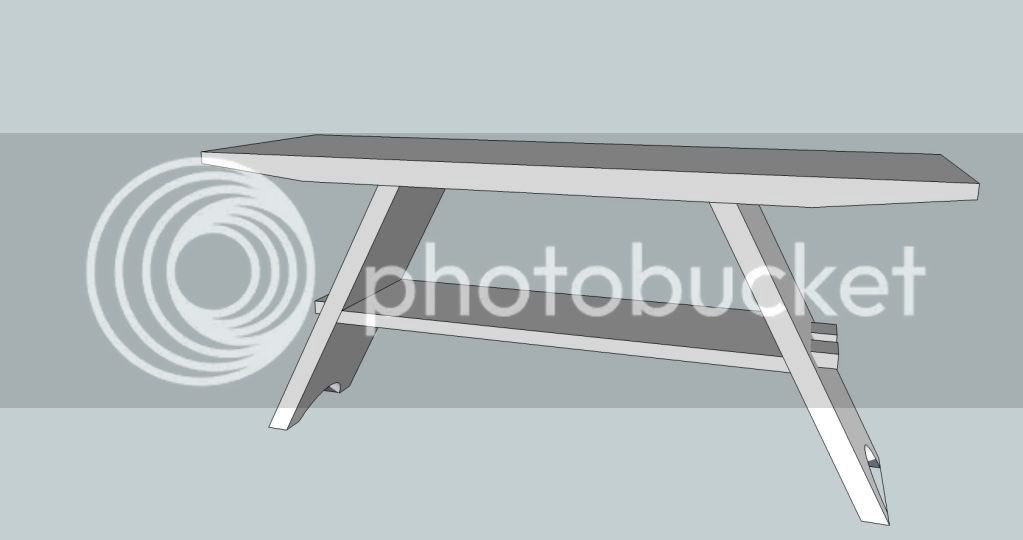

I'm currently building a very simple TV stand for my father based on the model below:

The top is 120cm long and about 40cm wide. How would you go about cutting the two angled ends of the top? Sadly my ceiling is too low over my table saw so thats not an option and I don't own a sufficiently good hand saw to do it by hand. I'm currently thinking of using the band saw to rough cut the two 20cm wide parts of the top and then hand planing it smooth and true after they've been glued up.

I was wondering if anyone had a better suggestion.

The wood is sycamore. Any finishing suggestions that don't involve spraying or subsequent yellowing of the wood would also be gratefully received.

Many thanks

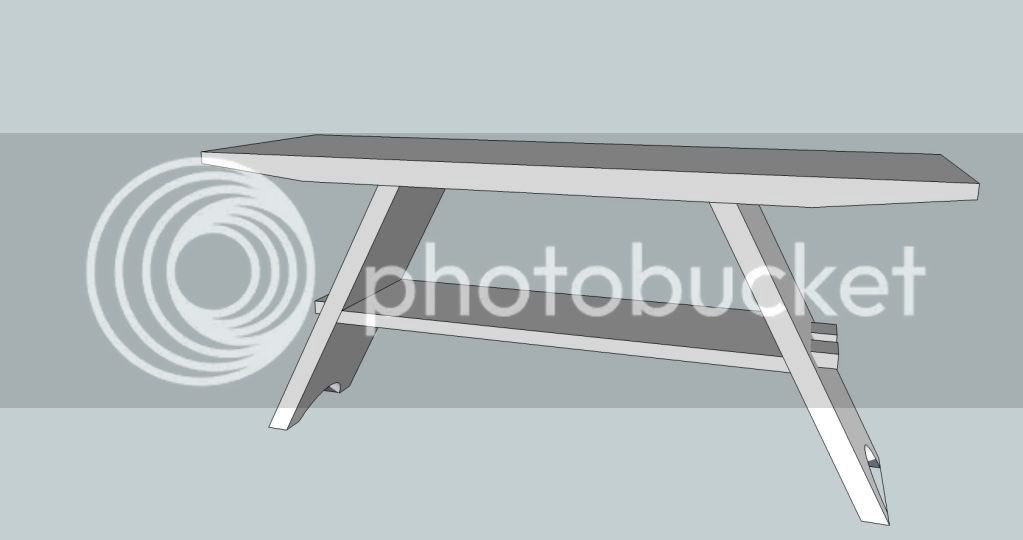

The top is 120cm long and about 40cm wide. How would you go about cutting the two angled ends of the top? Sadly my ceiling is too low over my table saw so thats not an option and I don't own a sufficiently good hand saw to do it by hand. I'm currently thinking of using the band saw to rough cut the two 20cm wide parts of the top and then hand planing it smooth and true after they've been glued up.

I was wondering if anyone had a better suggestion.

The wood is sycamore. Any finishing suggestions that don't involve spraying or subsequent yellowing of the wood would also be gratefully received.

Many thanks