Hi all, good morning to you.

I dont see newbie section so I'll put this in here.

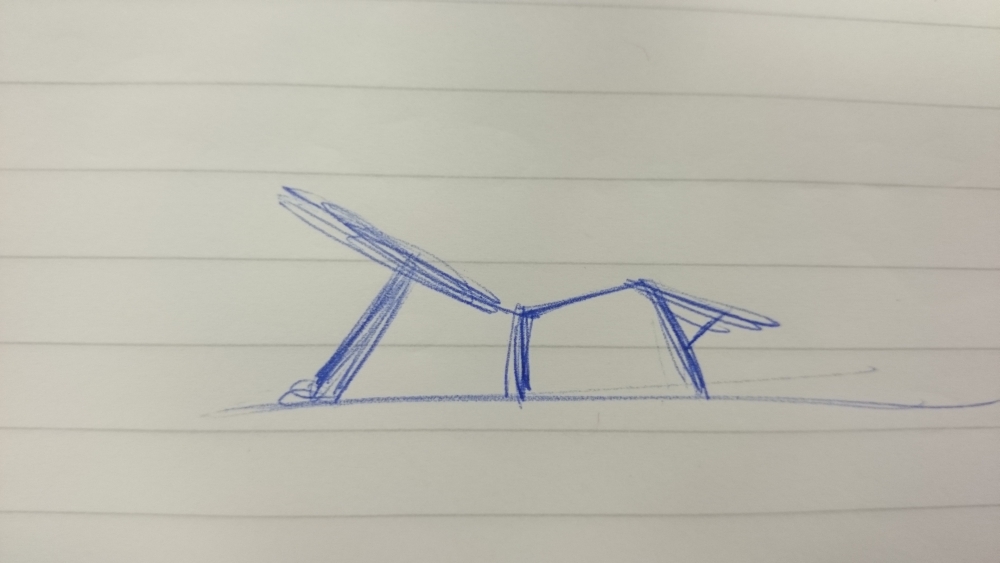

We want a garden bench, so I said, okay, I'll throw one together, get it done fast, it'll be grand. So I made that, which you can see below. But then the problem formed in my head, that's not pretty enough dammit, it needs to be prettier. So I'm in the process of making it more interesting to the eye.

It will be obvious from the pics below I am no carpenter or woodworker. My material is steel, and no matter how many woodworking tools I buy, I find it hard to invest mentally in the material. I don't know how that reads to you, but what it means in practical terms is that I have zero interest in doing dovetail joints or similar to bond this.

But, saying that, if someone can suggest a really cool or suitable joint I might give it a go.

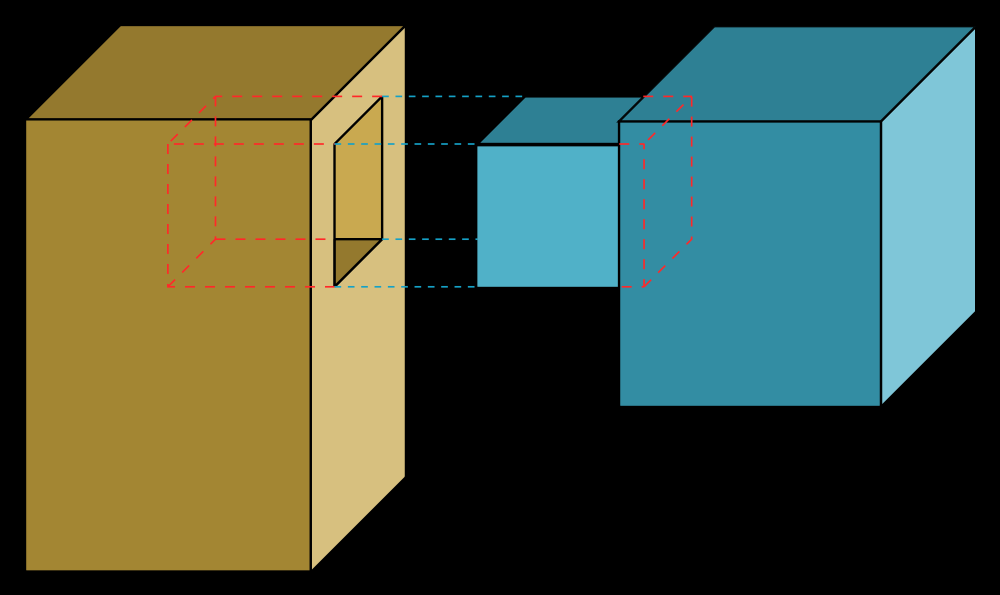

Ideally I'd like to bind the back and the sides with the stuff they use to bond rafters together, the metal plates with hundreds of spikes in them, I don't know what they are called.

Can anyone suggest alternative, easy ways to put this together please? At the moment its aligned with biscuit joints and thats all.

If I cant find a better idea I'll weld together some metal to support the back and sides, for each joint.

You can see the first version has metal plates to hold it together, but I think they look rubbish. I would like to just have bare wood on the surface facing the viewer.

The below are in chronological order:

latest version, need to fix this together, would love suggestions... dowels? joints? metal sections, glue?

It needs to be strong because I'm going to be drunk, and standing on this. I weigh 12 stone.

thanks for reading,

redd .

I dont see newbie section so I'll put this in here.

We want a garden bench, so I said, okay, I'll throw one together, get it done fast, it'll be grand. So I made that, which you can see below. But then the problem formed in my head, that's not pretty enough dammit, it needs to be prettier. So I'm in the process of making it more interesting to the eye.

It will be obvious from the pics below I am no carpenter or woodworker. My material is steel, and no matter how many woodworking tools I buy, I find it hard to invest mentally in the material. I don't know how that reads to you, but what it means in practical terms is that I have zero interest in doing dovetail joints or similar to bond this.

But, saying that, if someone can suggest a really cool or suitable joint I might give it a go.

Ideally I'd like to bind the back and the sides with the stuff they use to bond rafters together, the metal plates with hundreds of spikes in them, I don't know what they are called.

Can anyone suggest alternative, easy ways to put this together please? At the moment its aligned with biscuit joints and thats all.

If I cant find a better idea I'll weld together some metal to support the back and sides, for each joint.

You can see the first version has metal plates to hold it together, but I think they look rubbish. I would like to just have bare wood on the surface facing the viewer.

The below are in chronological order:

latest version, need to fix this together, would love suggestions... dowels? joints? metal sections, glue?

It needs to be strong because I'm going to be drunk, and standing on this. I weigh 12 stone.

thanks for reading,

redd .