You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Extractor fan for spray booth Heeeelp?

- Thread starter seaco

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

RobertMP

Established Member

I extracted using a plate fan in the wall when I did my spraying and it worked really well. In front of the fan I mounted a filter frame which had the innards from an old sleeping bag as a filter. Nothing at all got through to the back of the filter even when it was near to being fully loaded on the face.

Pictures are in my kitchen thread here about halfway down page 2. The filter isn't pictured though.

The first link I turned up on google for the fan was this one -

http://www.mathews.co.uk/acatalog/Single_Phase_Fans.html

Though mine is black it colour it looks similar. I also have the louvre flap cover / guard on the outside.

The filter worked so well I would think allowing the air to stay in the room would not be a problem. I've seen similar filter sold for spraying on ebay.

Pictures are in my kitchen thread here about halfway down page 2. The filter isn't pictured though.

The first link I turned up on google for the fan was this one -

http://www.mathews.co.uk/acatalog/Single_Phase_Fans.html

Though mine is black it colour it looks similar. I also have the louvre flap cover / guard on the outside.

The filter worked so well I would think allowing the air to stay in the room would not be a problem. I've seen similar filter sold for spraying on ebay.

9fingers

Established Member

seaco":2k0nxser said:Hi Bob

I am completely green when it comes to motors how would I tell if it's an induction motor and as for a over temperature cut out switch, I wouldn't know one of those if I saw one?

The easiest way of spotting a non induction motor is the presence of brushes - carbon blocks pressing on the a section at the end of the motor shaft.

As for the cut out switch, this would be another device with two wires mounted on the iron of the static (stator) part of the motor in addition to the coils. These could appear on a brush or an induction motor.

The reason to avoid brush motors is that under normal operation there are a steady stream of small sparks generated.

hth

Bob

RobertMP":j1e6c4wv said:I extracted using a plate fan in the wall when I did my spraying and it worked really well. In front of the fan I mounted a filter frame which had the innards from an old sleeping bag as a filter. Nothing at all got through to the back of the filter even when it was near to being fully loaded on the face.

Pictures are in my kitchen thread here about halfway down page 2. The filter isn't pictured though.

The first link I turned up on google for the fan was this one -

http://www.mathews.co.uk/acatalog/Single_Phase_Fans.html

Though mine is black it colour it looks similar. I also have the louvre flap cover / guard on the outside.

The filter worked so well I would think allowing the air to stay in the room would not be a problem. I've seen similar filter sold for spraying on ebay.

Hi Robert

I have seen these for sale are they safe to use with spirit vapours as obviously they will get past the filter?

9fingers":j1e6c4wv said:The easiest way of spotting a non induction motor is the presence of brushes - carbon blocks pressing on the a section at the end of the motor shaft.

As for the cut out switch, this would be another device with two wires mounted on the iron of the static (stator) part of the motor in addition to the coils. These could appear on a brush or an induction motor.

The reason to avoid brush motors is that under normal operation there are a steady stream of small sparks generated.

hth

Bob

Thanks for the info Bob I'll have to have a look when I'm next there (Monday) and report back!

9fingers

Established Member

Lee,

Having thought about it, I'm pretty sure the vent axia will be an induction motor.

Another couple of characteristics of brush motors are high speed and relatively noisy. Neither of which would be desirable for a domestic fan.

Bob

Having thought about it, I'm pretty sure the vent axia will be an induction motor.

Another couple of characteristics of brush motors are high speed and relatively noisy. Neither of which would be desirable for a domestic fan.

Bob

Ironballs

Established Member

Lee - let me know what you end up doing, I had a brief look into this a couple of months back. I'm considering spraying a guitar myself with nitrocellulose and in the interests of not killing myself with fumes was looking to build a small booth with extractor, came unstuck when trying to find an explosion proof extractor fan that wasn't part of a multi thousand pound booth installation

Reckon if you do it and do it we, there could be plenty of interest on here as a spray booth build how to for spraying solvents

Cheers

Damian

Reckon if you do it and do it we, there could be plenty of interest on here as a spray booth build how to for spraying solvents

Cheers

Damian

BradNaylor

Established Member

- Joined

- 17 Oct 2007

- Messages

- 2,311

- Reaction score

- 2

Possibly too big for your application but my advice to anyone contemplating a spraybooth is to look for a complete second-hand set-up.

I have bought and sold several over the last 25 years or so and have never paid more than £300 for a complete spraybooth including fan and motor.

Machinery dealers who specialise in buying the entire contents of bankrupt factories are often glad to give the sprayshop equipment away to anyone who will dismantle and clear it.

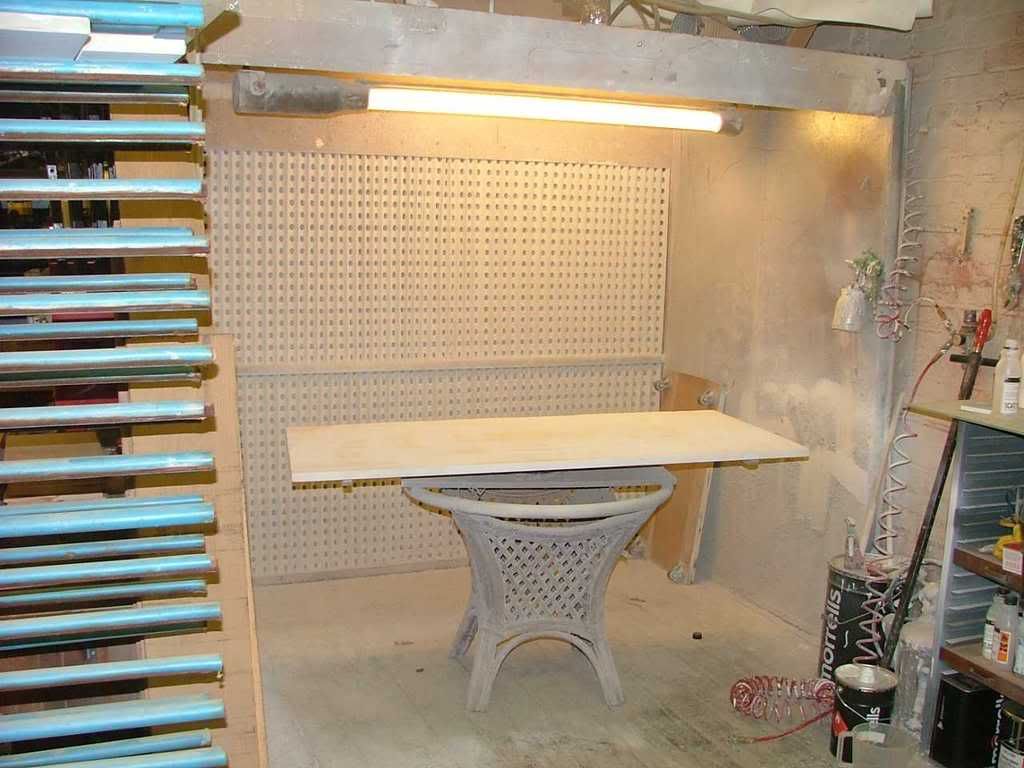

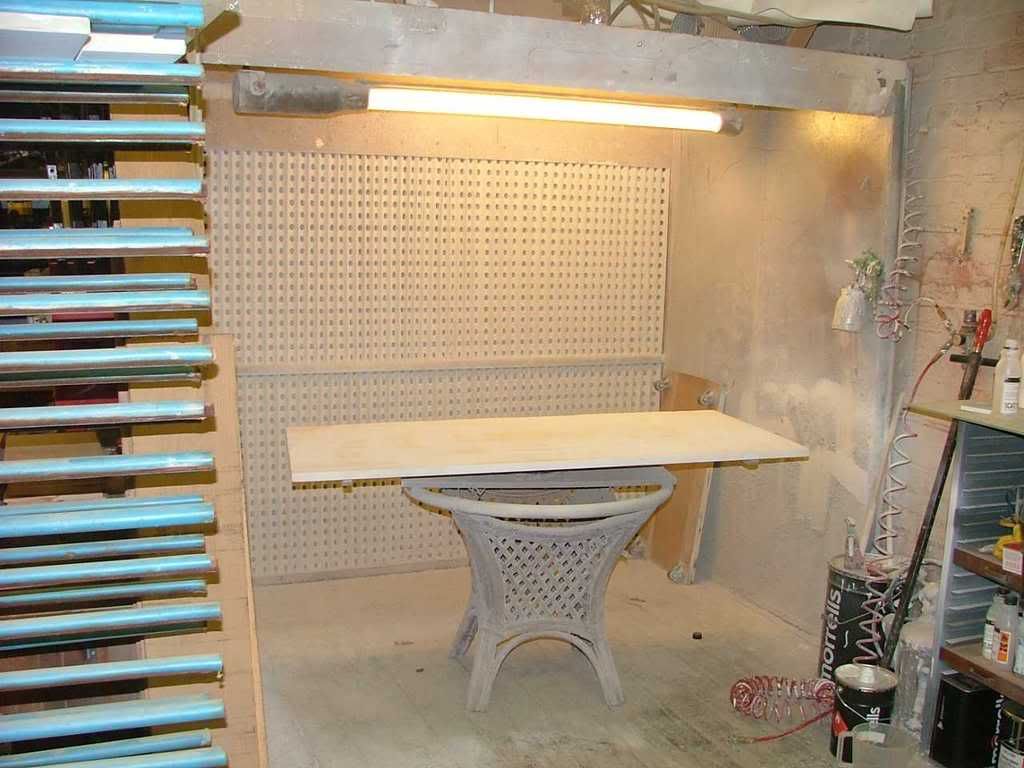

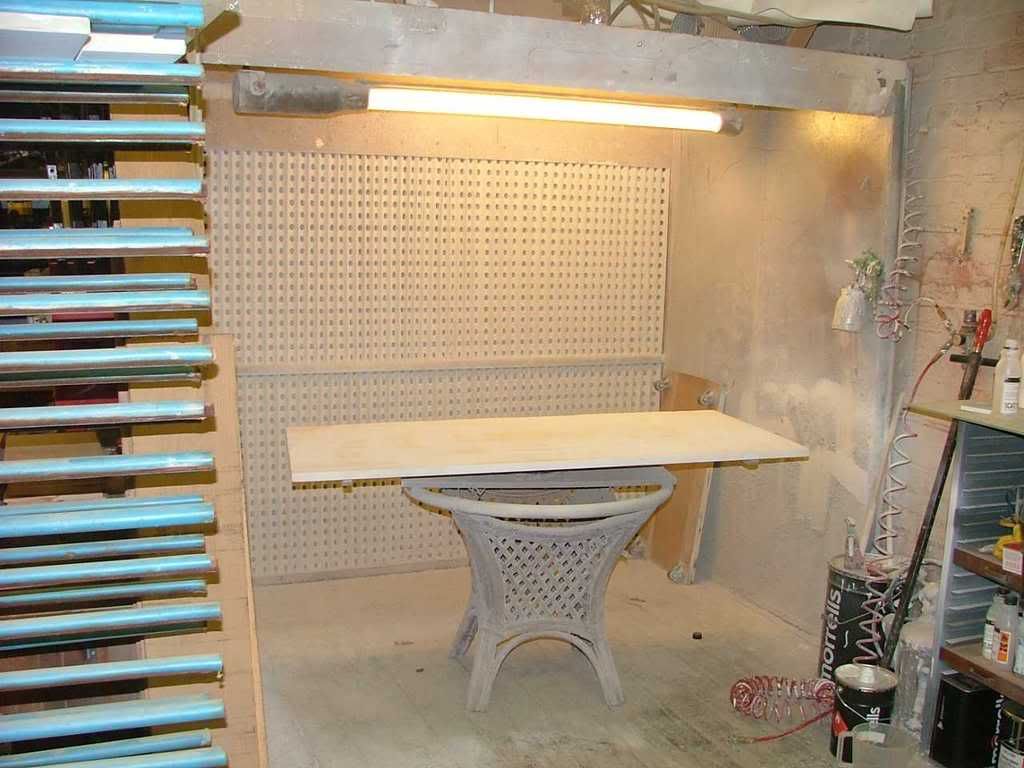

This is my set up - £300 all in.

Cheers

Dan

I have bought and sold several over the last 25 years or so and have never paid more than £300 for a complete spraybooth including fan and motor.

Machinery dealers who specialise in buying the entire contents of bankrupt factories are often glad to give the sprayshop equipment away to anyone who will dismantle and clear it.

This is my set up - £300 all in.

Cheers

Dan

RobertMP

Established Member

I'm only a hobbyist now so I don't have to worry about factory inspectors and regulations. The fan I use is not rated for anything more than extracting air. The terminals and motor are fully enclosed though not to zone 2 or whatever the spec should be for flammable vapours.

We had a spray booth in my business though it was for powder coating not wet spray. The fan on that was back behind the filters and was a centrifugal fan (like on a basic dust extractor blower but larger) with the motor external to the booth enclosure. We bought the booth second hand along with the rest of the powder coating plant. The booth was scrapped when we closed the business so I'd agree you might find something cheap at a dealer( or ebay as we sold off most of our surplus stuff on ebay!).

We had a spray booth in my business though it was for powder coating not wet spray. The fan on that was back behind the filters and was a centrifugal fan (like on a basic dust extractor blower but larger) with the motor external to the booth enclosure. We bought the booth second hand along with the rest of the powder coating plant. The booth was scrapped when we closed the business so I'd agree you might find something cheap at a dealer( or ebay as we sold off most of our surplus stuff on ebay!).

Hi All

Just an update Jake kindly sent me a link to an extractor fan going on Ebay it was bought for a spray booth but never used what do you all think will it be ok I only had a couple of hours to decide so went for it and got it for £27...

Just an update Jake kindly sent me a link to an extractor fan going on Ebay it was bought for a spray booth but never used what do you all think will it be ok I only had a couple of hours to decide so went for it and got it for £27...

Oryxdesign

Established Member

Dan Tovey":tmharof9 said:Possibly too big for your application but my advice to anyone contemplating a spraybooth is to look for a complete second-hand set-up.

I have bought and sold several over the last 25 years or so and have never paid more than £300 for a complete spraybooth including fan and motor.

Machinery dealers who specialise in buying the entire contents of bankrupt factories are often glad to give the sprayshop equipment away to anyone who will dismantle and clear it.

This is my set up - £300 all in.

Cheers

Dan

Dan do you have an active carbon filter on the back of your booth to remove odours, have you ever had any complaints about smell? Thanks Simon

Jake":nih04jbb said:Why not call Air Vent Technology and see what they say?

Due diligence, as it were.

Just done that Jake and the news wasn't good...

"Sorry to disappoint, but our fans are not ATEX certified, and therefore unsuitable for extracting potentially flammable vapours.

We don’t supply such equipment, but can point you in the right direction if need be".

Regards

Oliver Behegan

big soft moose

Established Member

- Joined

- 22 May 2008

- Messages

- 5,079

- Reaction score

- 0

lee - i'm after an extractor fan to power a home built dust collector. If you dont want that one i'll buy it off you for the 27 notes you paid. I'm in wiltshire so i could probably pick it up depending where in zummerzet you are.

pm me

Pete

pm me

Pete

Phew, BSM, it sounds like you might salve my guilt for bringing the listing to Lee's attention.

If not, I think I'd complain to the seller about misdescription if I were you, Lee - but it's borderline - whether by ignorance or design.

If not, I think I'd complain to the seller about misdescription if I were you, Lee - but it's borderline - whether by ignorance or design.

In fact, BSM's idea is fantastic, so if that doesn't work out between you and him, I'll step in and do the same (been meaning to make a dust filter for ages).

There are definitely ATEX rated fans listed in the same category (albeit with 3 phase motor, so you'd need a little inverter, presumably).

There are definitely ATEX rated fans listed in the same category (albeit with 3 phase motor, so you'd need a little inverter, presumably).

Similar threads

- Replies

- 4

- Views

- 385

- Replies

- 18

- Views

- 3K

- Replies

- 5

- Views

- 2K

- Replies

- 17

- Views

- 984