David -

Mia Iwasaki translated this (I'm pretty sure it was her) in April of 2012, I found it in my email. I recall Bill Tindall being pretty disappointed in how vague it was as he was looking for something as you are - something that provides a setting and paramaters.

Credit goes to the same professors and collegiate resources as provided with the original videos (it was important to K&K that they are credited each time their work is shared - that was relayed to me by Bill).

At any rate, here it is:

Technical Studies on Education of Orthogonal Cutting of 百九 food II Cutting force and chip length in cutting parallel to the grain by knife with cap iron by y 畠 sunoriKAWAI*,Chutaro KATO*昌 ndKenji Y AMANISHI** *Faculty of Education,Yam 昌伊 taUniversity 場 場 場 *JoetsuUniv 号 rsityof EducationSummary:

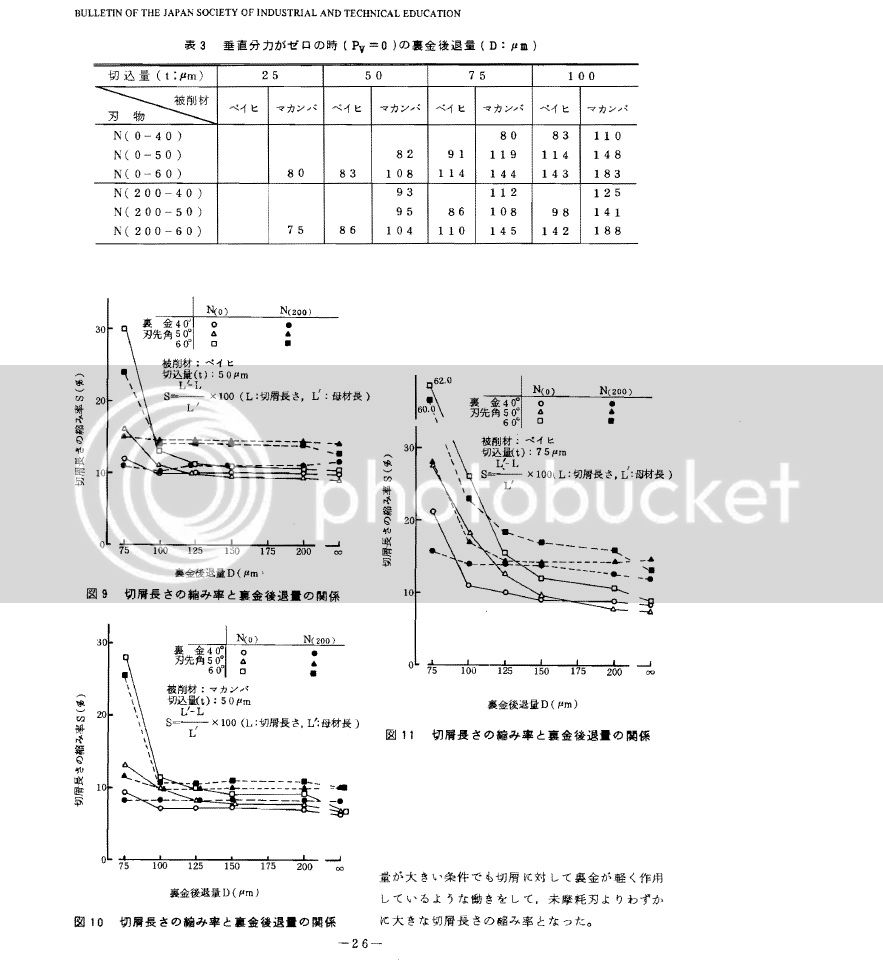

The objective of the work was to investigate the influence of capiron angle and cap iron recess on the level/quality/amount of the work on the shaving in double blade planing. The cutting force/resistance and length of shaving .

1. Average double blade resistance(planing force) increased with amount of cap iron effect compared to single blade.

2. In that occasion horizontal force starting from condition when shavings are not touching cap iron, started to show change. In vertical force, from point where shaving started to touch cap iron sufficiently the change startedto show clearly (sharp change).

3. Cutting resistance range showed the tendency to increase in accordancewith cap iron effect.

4. Shaving length is thought to be a favorable factor to determine the effectof cap iron on shaving by observation (looking at it with naked eye).

5. Also length of shaving reacted sensitively to the wear of the blade whichcould not be observed by cutting force.

6. Analyzing the use of hand planes can say:Setting cap iron can not be done by eye. Must take a test shaving and judge work(effect of) of cap iron little by little with precise adjustment. For judging, one of the methods is to measure length of shaving. [I presume that the cap iron is adjusted close, but not so close that a scrunched shaving results.]

My translation of the translation, shaving length means how the shaving straightens up out of the plane (I recall that from conversation). They liked relying on what was happening to the shaving to determine whether or not they had a good set.

For #6, I believe they were using a japanese plane, which has the iron and cap iron (or blade and subblade to appease those into the japanese planes) hidden under the wear when in the plane. I think that is why they are saying that you can't set the iron and cap iron by eye. Maybe their eyesight wasn't that good, though, I could be wrong with that guess.

In the case where you have an iron and double iron that can be affixed securely to each other, you can certainly set them by eye reliably, I have good eyesight so I can't say for sure you can do it with bad eyesight, but I think you can do it with bad eyesight and a decent light source. I have tested planes for people, and the ones that come with a flat cap iron milled precisely and finely, it's a little bit harder to differentiate the difference between the iron and cap iron. In the case of those planes, I've found it helpful to gun blue the cap iron so that it is easy to tell it apart from the iron (and then the light only shines back off of the iron). Talking about this is harder than doing, the "do" of the setting is over in 10 or 15 seconds.

I have some back and forth emails from this (this was Bill and Steve Elliot's baby, to do all of the work to dig this stuff up - their efforts and Bill was only including me to see if I thought their translations made sense from an actual use standpoint), but what I remember the gist was that the professors suggested they had trouble providing specific prescriptions for hand planes and never went into the same level of detail that they did for the machine-based testing (which, IIRC, was intended for industrial use). Or to put it more briefly, I think they decided that they couldn't come up with more specific instructions than the above, but the hand plane instructions were only an off shoot of the original study, so they weren't bothered by that.

Mia Iwasaki translated this (I'm pretty sure it was her) in April of 2012, I found it in my email. I recall Bill Tindall being pretty disappointed in how vague it was as he was looking for something as you are - something that provides a setting and paramaters.

Credit goes to the same professors and collegiate resources as provided with the original videos (it was important to K&K that they are credited each time their work is shared - that was relayed to me by Bill).

At any rate, here it is:

Technical Studies on Education of Orthogonal Cutting of 百九 food II Cutting force and chip length in cutting parallel to the grain by knife with cap iron by y 畠 sunoriKAWAI*,Chutaro KATO*昌 ndKenji Y AMANISHI** *Faculty of Education,Yam 昌伊 taUniversity 場 場 場 *JoetsuUniv 号 rsityof EducationSummary:

The objective of the work was to investigate the influence of capiron angle and cap iron recess on the level/quality/amount of the work on the shaving in double blade planing. The cutting force/resistance and length of shaving .

1. Average double blade resistance(planing force) increased with amount of cap iron effect compared to single blade.

2. In that occasion horizontal force starting from condition when shavings are not touching cap iron, started to show change. In vertical force, from point where shaving started to touch cap iron sufficiently the change startedto show clearly (sharp change).

3. Cutting resistance range showed the tendency to increase in accordancewith cap iron effect.

4. Shaving length is thought to be a favorable factor to determine the effectof cap iron on shaving by observation (looking at it with naked eye).

5. Also length of shaving reacted sensitively to the wear of the blade whichcould not be observed by cutting force.

6. Analyzing the use of hand planes can say:Setting cap iron can not be done by eye. Must take a test shaving and judge work(effect of) of cap iron little by little with precise adjustment. For judging, one of the methods is to measure length of shaving. [I presume that the cap iron is adjusted close, but not so close that a scrunched shaving results.]

My translation of the translation, shaving length means how the shaving straightens up out of the plane (I recall that from conversation). They liked relying on what was happening to the shaving to determine whether or not they had a good set.

For #6, I believe they were using a japanese plane, which has the iron and cap iron (or blade and subblade to appease those into the japanese planes) hidden under the wear when in the plane. I think that is why they are saying that you can't set the iron and cap iron by eye. Maybe their eyesight wasn't that good, though, I could be wrong with that guess.

In the case where you have an iron and double iron that can be affixed securely to each other, you can certainly set them by eye reliably, I have good eyesight so I can't say for sure you can do it with bad eyesight, but I think you can do it with bad eyesight and a decent light source. I have tested planes for people, and the ones that come with a flat cap iron milled precisely and finely, it's a little bit harder to differentiate the difference between the iron and cap iron. In the case of those planes, I've found it helpful to gun blue the cap iron so that it is easy to tell it apart from the iron (and then the light only shines back off of the iron). Talking about this is harder than doing, the "do" of the setting is over in 10 or 15 seconds.

I have some back and forth emails from this (this was Bill and Steve Elliot's baby, to do all of the work to dig this stuff up - their efforts and Bill was only including me to see if I thought their translations made sense from an actual use standpoint), but what I remember the gist was that the professors suggested they had trouble providing specific prescriptions for hand planes and never went into the same level of detail that they did for the machine-based testing (which, IIRC, was intended for industrial use). Or to put it more briefly, I think they decided that they couldn't come up with more specific instructions than the above, but the hand plane instructions were only an off shoot of the original study, so they weren't bothered by that.