Derek Cohen (Perth Oz)

Established Member

sihollies":2zogjbd4 said:Hi

I have been asked what I want for Christmas, and decided that a cutting gauge would be handy.

I made one several years ago, which works in the main, but I wouldn't mind a proper one.

I am aware that Marples do one, but was wondering if anyone had any recommendations?

I will mainly be using it for trimming veneers ready for the stringing and banding.

Thanks in advance

Simon

Simon

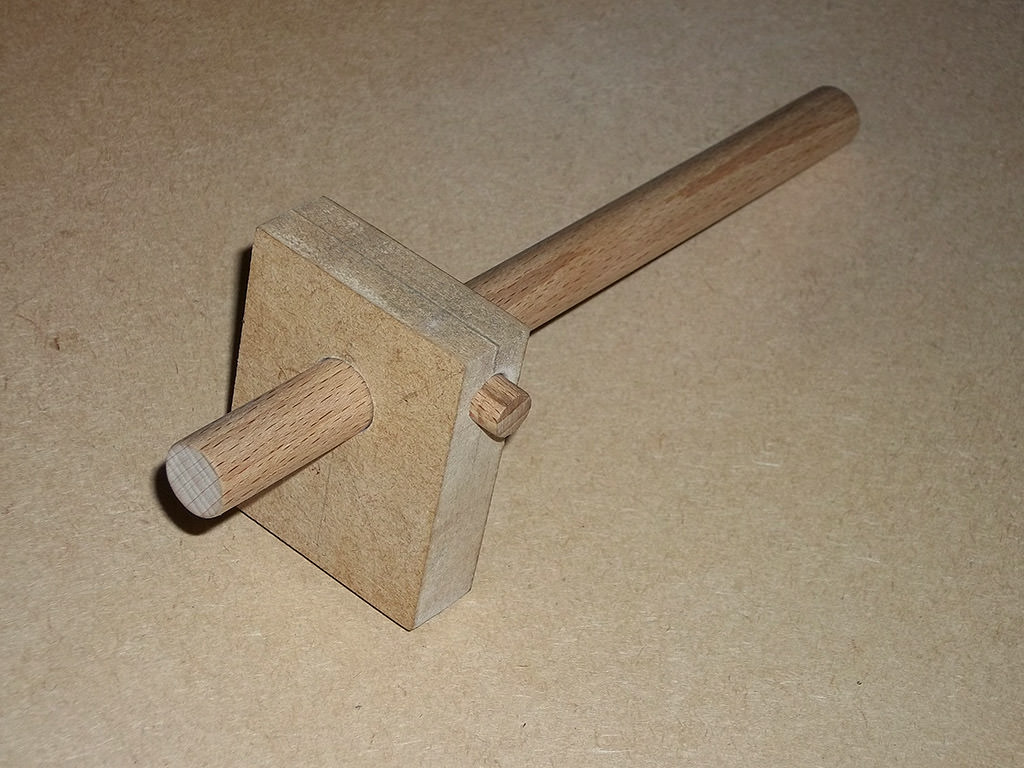

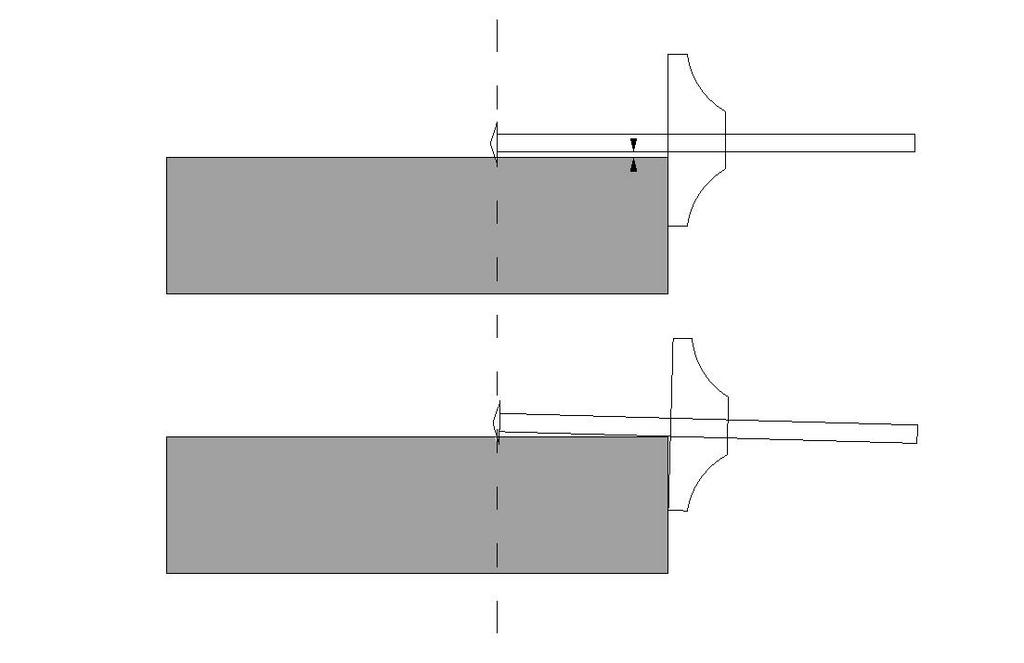

Since you have stated a desire to purchase rather than make a gauge, and it is needed for veneer, I would recommend a wheel gauge. These cut a fine line, one that is less likely to tear the thin veneer. For the best, look at the Tite-Mark and the latest Veritas gauges.

Regards from Perth

Derek