I'm looking into the options of getting a CNC machine or laser cutting machine to expand the range of 1/12th scale fireplaces I can make.

I can only afford the entry level type machines - ~£1K

For that sort of money, what options are available? I'm wondering what the advantages and disadvantages are of the two types of machine.

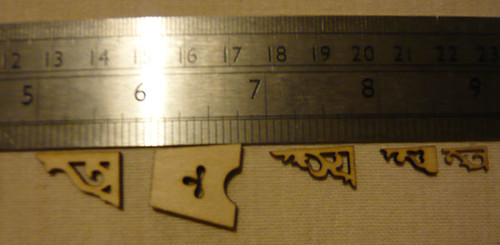

I have some samples of laser cutting done so I know it can cut out extremely fine detail but everything is 2D. The samples I have though were cut on a machine costing £18K so appart from speed and ability to cut through thicker wood /materials, can a cheap machine still do the job?

I'm also wondering about reliability as this has come up because I was going to get some false hinges, fret work etc cut on a laser cutter (the £18K one) but it has broken down and is beyond repair so the guy has folded, hence I'm looking at options. I'm learning that relying on other people is risky so I'd like to be able to do as much stuff myself as I can.

If laser cutters have high maintenance costs (I know the one I saw for £1K has a laser lifespan of 1000-1500 hours), is it really a viable option?

I can't afford for it to break down or need replacing every year etc... and maintenance alone was £175 / year for this particular model with a new laser costing £300. (HPC laser 3020 pro)

I see a CNC router being more versatile as I could cut 3D shapes and mouldings but how fine a detail can you get with them?

1/12th scale stuff can be very finely detailed - say for miniature fretwork etc.

I would ideally like to be able to go along to a shop and see them in action but I'm struggling to find anywhere local to Manchester. Does anyone know of any shops I could go to?

Any advice would be greatly appreciated. If you want examples of what sort of thing I'm talking about I can post a couple of photos if it would help.

thanks,

Jennifer,

I can only afford the entry level type machines - ~£1K

For that sort of money, what options are available? I'm wondering what the advantages and disadvantages are of the two types of machine.

I have some samples of laser cutting done so I know it can cut out extremely fine detail but everything is 2D. The samples I have though were cut on a machine costing £18K so appart from speed and ability to cut through thicker wood /materials, can a cheap machine still do the job?

I'm also wondering about reliability as this has come up because I was going to get some false hinges, fret work etc cut on a laser cutter (the £18K one) but it has broken down and is beyond repair so the guy has folded, hence I'm looking at options. I'm learning that relying on other people is risky so I'd like to be able to do as much stuff myself as I can.

If laser cutters have high maintenance costs (I know the one I saw for £1K has a laser lifespan of 1000-1500 hours), is it really a viable option?

I can't afford for it to break down or need replacing every year etc... and maintenance alone was £175 / year for this particular model with a new laser costing £300. (HPC laser 3020 pro)

I see a CNC router being more versatile as I could cut 3D shapes and mouldings but how fine a detail can you get with them?

1/12th scale stuff can be very finely detailed - say for miniature fretwork etc.

I would ideally like to be able to go along to a shop and see them in action but I'm struggling to find anywhere local to Manchester. Does anyone know of any shops I could go to?

Any advice would be greatly appreciated. If you want examples of what sort of thing I'm talking about I can post a couple of photos if it would help.

thanks,

Jennifer,