Hi there,

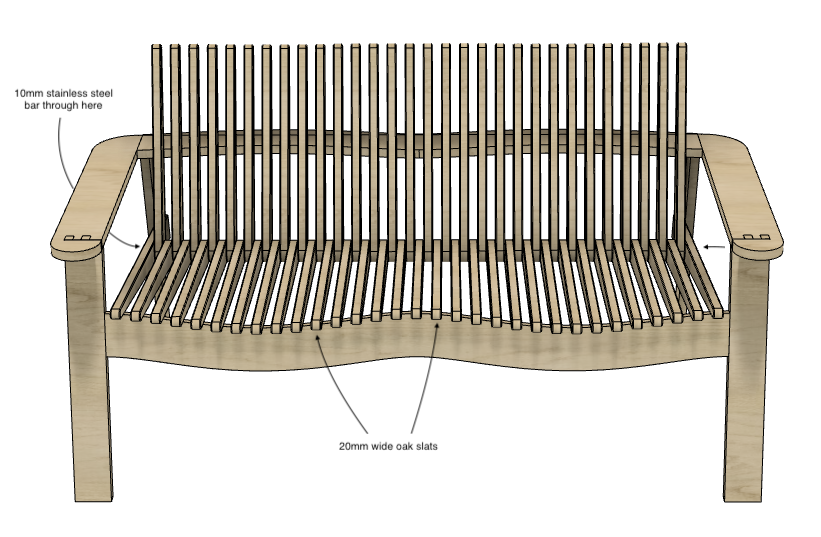

I am making a garden bench out of air-dried english oak boards. The bench will have interlocking slats for the seat and back (running fore and aft, and up and down, rather than along the bench). I have posted a couple of pics below.

My original plan was to thread the 20mm wide slats tightly together onto a 10mm stainless steel bar running the length of the bench where the slats interlock (at the back of the seat / base of the back). I planned to thread the ends of the bar and secure with s/s nuts and washers at each end.

However, now I am wondering what will happen when the bench gets saturated with rain? The oak will obviously want to expand but would a 10mm s/s bar stop them expanding and just cause them to compress?

Or do I need to leave small gaps between the seat and the back slats - and if so how much gap?

Any ideas / thoughts / experience would be greatly appreciated.

Thanks

I am making a garden bench out of air-dried english oak boards. The bench will have interlocking slats for the seat and back (running fore and aft, and up and down, rather than along the bench). I have posted a couple of pics below.

My original plan was to thread the 20mm wide slats tightly together onto a 10mm stainless steel bar running the length of the bench where the slats interlock (at the back of the seat / base of the back). I planned to thread the ends of the bar and secure with s/s nuts and washers at each end.

However, now I am wondering what will happen when the bench gets saturated with rain? The oak will obviously want to expand but would a 10mm s/s bar stop them expanding and just cause them to compress?

Or do I need to leave small gaps between the seat and the back slats - and if so how much gap?

Any ideas / thoughts / experience would be greatly appreciated.

Thanks