Nail

Established Member

Good evening,

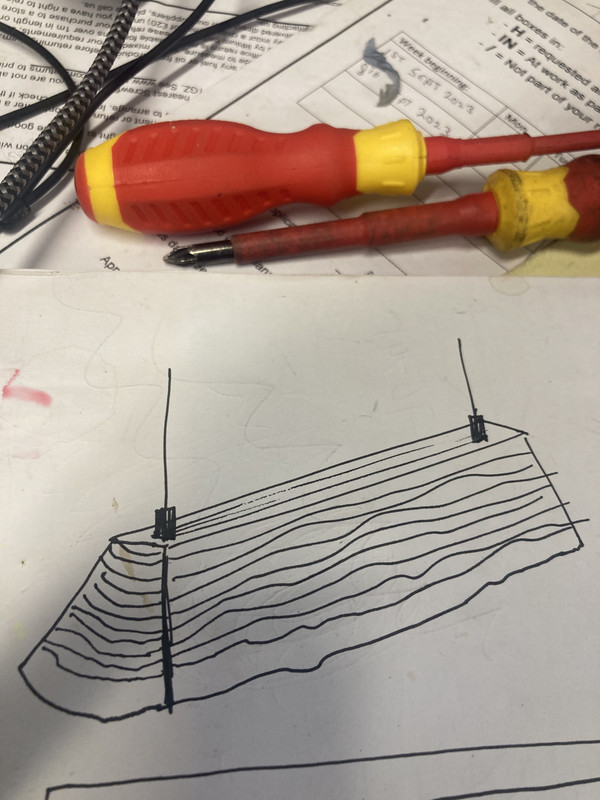

I’ve meant to ask this for a while but kept forgetting. I had planned to do a little sketch but perhaps text will suffice.

Essentially, I’m wondering if anyone has a view on a type of light for recessing into a log as a feature light.

A standard bit of strip LED would be too narrow and I’m conscious of the outer appearance. I could use multiple lengths to increase the width ( no set width yet - trying to be good and plan it first!) but then there is the appearance issue.

I’ve seen side emitting LEDs used for one but again, narrow.

I have wondered about cannibalising an LED baten for inner parts and also the diffuser but before I got into it too far wondered if anyone else had solved this problem of mine!

Thanks!

I’ve meant to ask this for a while but kept forgetting. I had planned to do a little sketch but perhaps text will suffice.

Essentially, I’m wondering if anyone has a view on a type of light for recessing into a log as a feature light.

A standard bit of strip LED would be too narrow and I’m conscious of the outer appearance. I could use multiple lengths to increase the width ( no set width yet - trying to be good and plan it first!) but then there is the appearance issue.

I’ve seen side emitting LEDs used for one but again, narrow.

I have wondered about cannibalising an LED baten for inner parts and also the diffuser but before I got into it too far wondered if anyone else had solved this problem of mine!

Thanks!