Time out from the kitchen build. Had my friend Ross this week for helping on a kitchen build, however Friday was always set aside for fry up and spray booth.

Last year I bought a 500mm fan off eBay and the cardboard filters in anticipation. I will only ever do WB stuff and generally stick to Morrells primer and top coat. Initially the plan is too recirculate the air, as taking it outside is problem.

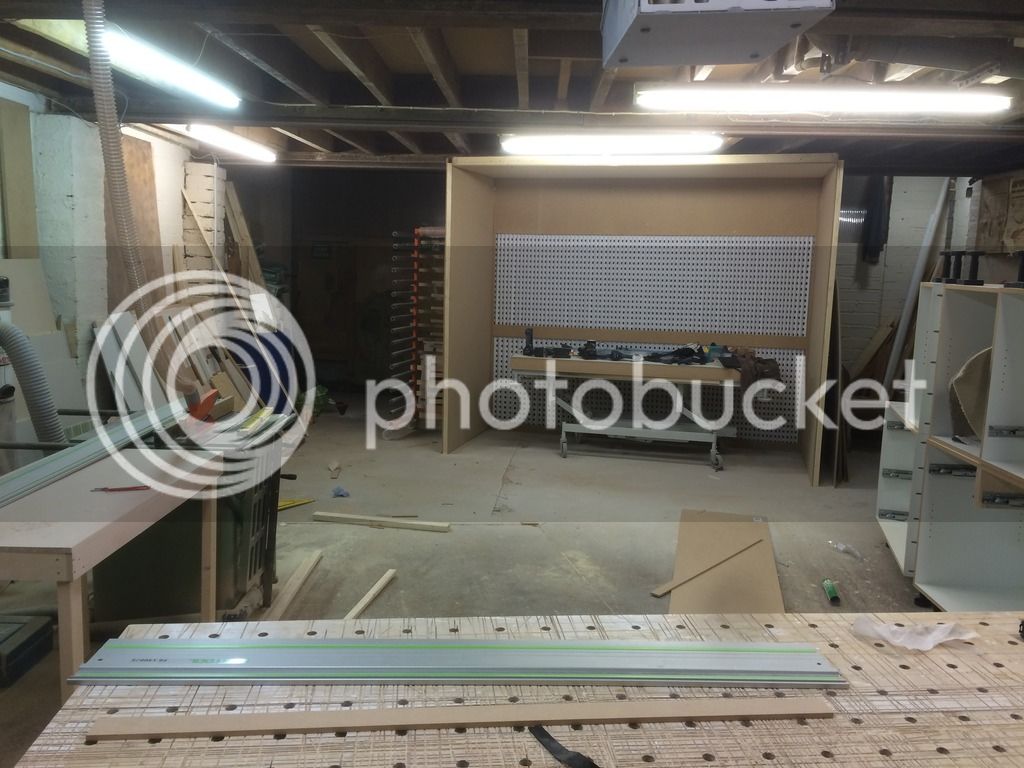

So far it's a 3m wall with two sets of 900mm high filters as you see in The picture. There will be 1-1.2m wing walls attached, thinking of hinging theses so I can close the booth. Then a ceiling just under the beam which is 2.4m high with a light box may be.

Area located for it

Sussing it out! It's a very adhoc build

Lower section done and a test fit.

Box on the back for the fan to sit on top

End of play. Not bad with a fry included and fetching materials. Probably another day and it be sorted.

Very happy for your thoughts.

Last year I bought a 500mm fan off eBay and the cardboard filters in anticipation. I will only ever do WB stuff and generally stick to Morrells primer and top coat. Initially the plan is too recirculate the air, as taking it outside is problem.

So far it's a 3m wall with two sets of 900mm high filters as you see in The picture. There will be 1-1.2m wing walls attached, thinking of hinging theses so I can close the booth. Then a ceiling just under the beam which is 2.4m high with a light box may be.

Area located for it

Sussing it out! It's a very adhoc build

Lower section done and a test fit.

Box on the back for the fan to sit on top

End of play. Not bad with a fry included and fetching materials. Probably another day and it be sorted.

Very happy for your thoughts.