happy woodworker

Member

- Joined

- 3 Jun 2011

- Messages

- 6

- Reaction score

- 0

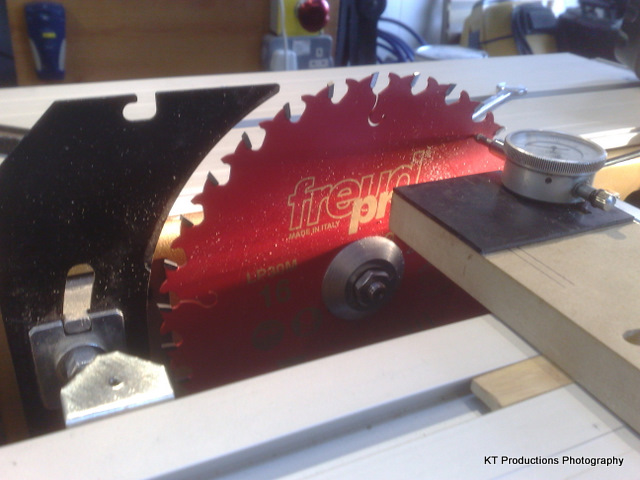

I have a Scheppach TS 2000 (table saw)

Generally, I am very happy with it but the blade is running slightly out along its length ie it does not run exactly parallel to the fence.

Ive stripped the saw down twice but can't see which screw/s I should be turning to adjust it. Also, I have to take the top off completely to get to where I think the adjustment screw/s is/are.

Doesn't seem to me to be a clever design when you have to go to all this to adjust the saw blade.

Can someone help me please with step by step instructions?

Thanks,

Happy Woodworker (not right now though!!!)

Generally, I am very happy with it but the blade is running slightly out along its length ie it does not run exactly parallel to the fence.

Ive stripped the saw down twice but can't see which screw/s I should be turning to adjust it. Also, I have to take the top off completely to get to where I think the adjustment screw/s is/are.

Doesn't seem to me to be a clever design when you have to go to all this to adjust the saw blade.

Can someone help me please with step by step instructions?

Thanks,

Happy Woodworker (not right now though!!!)