BigShot

Established Member

Hi folks,

I'm planning a small workshop in the garage. The floor space is smaller than the typical 1-car garage as there's already a wall partitioning the back off from the main part.

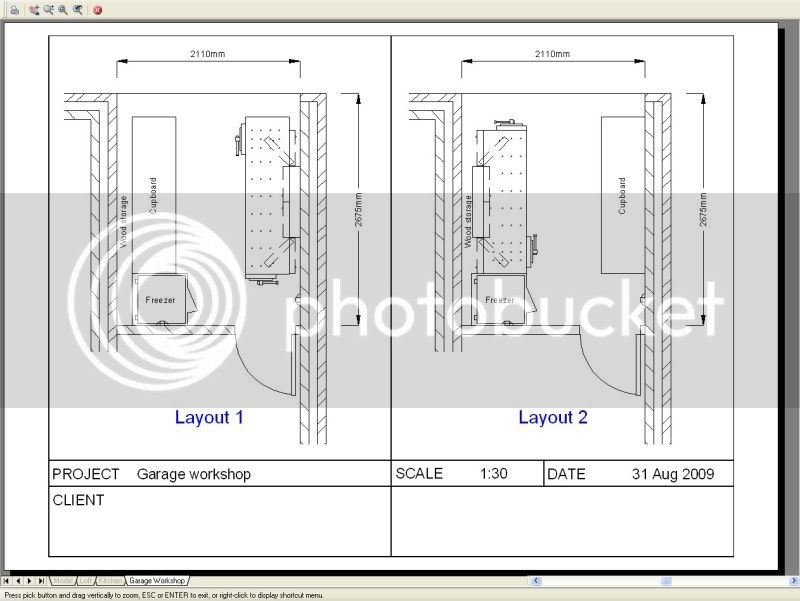

I've done a bit of a sketch in AutoCAD (a bit of a skive off from work) and would like some input on the layout and particularly some input on a couple of questions I have.

Firstly, the layouts:

You'll find a larger version of the image here.

To explain:

The garage door is a segmented up-and-over type so there has to be a gap between anything I put in there and the door to allow space for door hardware and rails. It also means I can't use the roof/ceiling as a storage area.

I'll refer to the end with the garage door as the "top end" and the end with the internal door as the "bottom end" - I'll use those terms with regards to things like the workbench too.

The ceiling height is 2250mm (about 7' 4")

The concrete floor slopes towards garage door (fall isn't excessive but I'll need to account for it when making things).

It's my intention to build some cupboards from the floor to just below the ceiling to store everyday stuff (currently it's all on open shelves) and also to enclose the small chest freezer. The main reason for this as opposed to keeping it all open is to keep things as dust free as possible.

I'll also have some shelves or small cupboards above the freezer (high enough above to allow the top to open fully).

The large thing over the workbench will be a tool cabinet along similar lines (though nothing like as big) as the one Lord Nibbo made as shown here.

The "wood storage" area is going to have to be smaller than I would like by necessity. Any wider and the space between cupboards and bench will become too small I think. It will mean less-than-ideal conditions for storing wood, but I don't anticipate having a huge stockpile anyway. Sheet stock would be stored on edge (gasp! horror! yea - I know) as would wider planks.

Option 2 does have a slightly smaller workbench, but in that case I'd build up the (top opening) enclosure for the chest freezer to the same level as the bench top effectively giving a bench almost the full length of the garage. (Possibly without dog-holes for the last part though, depending on which one of a few approaches I take)

The main difference between options 1 and 2 seem to be:

Option 1 allows things to hang off both ends of the bench.

Option 1 allows me to get around the end of the bench (by the end vise).

Option 1 allows things to hang off both ends of the bench.

Option 2 has potential for a longer "bench" when using the freezer cabinet top too.

I suppose Option 2 still provides a useful space on top of the freezer for putting things like grinders for sharpening chisels, irons, gouges and the likes.

Power tool storage will mostly be below the bench, though some may go in the cupboards if there's not enough space there. I've got to find a home for a bench-top bandsaw, a lathe, a table saw, a few grinders, a bench-top pillar drill, some hand power tools like sanders and so on. The table saw is on legs, but I expect I'll unscrew them, dump it all under the bench and just re-build the TS when I need it. It's FAR from ideal but I don't have enough space for ideal. I think I'll have enough space to store it all and though it means a complete pain-in-the-backside working method it's the best I can see for the space I have available.

Most likely I'll need to use the tablesaw outside on the driveway when it comes to things like 8x4 boards. I think things will be too cramped in the workshop to use a tablesaw and stand to the side for safety.

As I need the tools I'll most likely be taking them from under the bench and placing or clamping them on top, putting them on the freezer-cabinet or putting them on a "workmate" type thing I've got.

So - input please.

I'm after suggestions about which layout seems better (particularly which would make for a "better" bench) and any improvements you can suggest.

The wood storage can't be as wide as I would like, but can you suggest an "absolute minimum" if there is such a thing? I'd like to store as much as I can lying flat, but anything wide will have to go on edge.

A bit of a long post, thanks for reading and I look forwards to any replies you can give.

I'm planning a small workshop in the garage. The floor space is smaller than the typical 1-car garage as there's already a wall partitioning the back off from the main part.

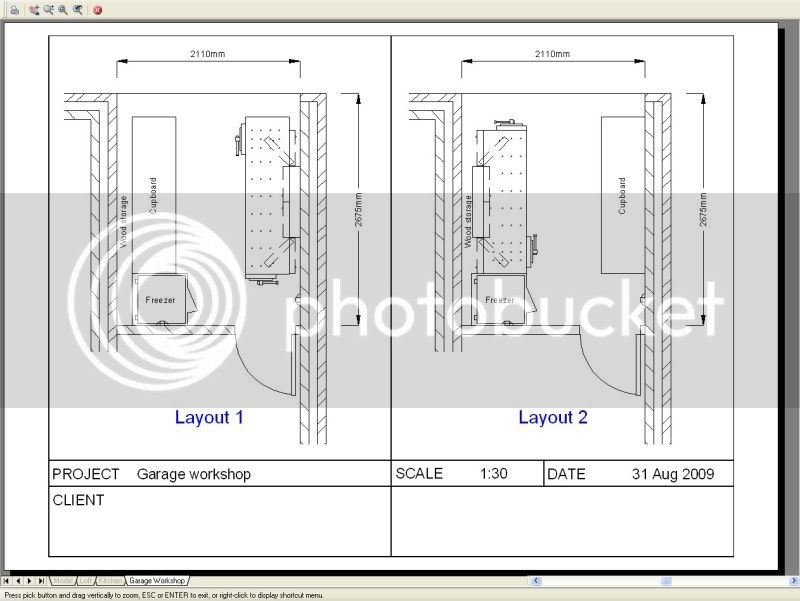

I've done a bit of a sketch in AutoCAD (a bit of a skive off from work) and would like some input on the layout and particularly some input on a couple of questions I have.

Firstly, the layouts:

You'll find a larger version of the image here.

To explain:

The garage door is a segmented up-and-over type so there has to be a gap between anything I put in there and the door to allow space for door hardware and rails. It also means I can't use the roof/ceiling as a storage area.

I'll refer to the end with the garage door as the "top end" and the end with the internal door as the "bottom end" - I'll use those terms with regards to things like the workbench too.

The ceiling height is 2250mm (about 7' 4")

The concrete floor slopes towards garage door (fall isn't excessive but I'll need to account for it when making things).

It's my intention to build some cupboards from the floor to just below the ceiling to store everyday stuff (currently it's all on open shelves) and also to enclose the small chest freezer. The main reason for this as opposed to keeping it all open is to keep things as dust free as possible.

I'll also have some shelves or small cupboards above the freezer (high enough above to allow the top to open fully).

The large thing over the workbench will be a tool cabinet along similar lines (though nothing like as big) as the one Lord Nibbo made as shown here.

The "wood storage" area is going to have to be smaller than I would like by necessity. Any wider and the space between cupboards and bench will become too small I think. It will mean less-than-ideal conditions for storing wood, but I don't anticipate having a huge stockpile anyway. Sheet stock would be stored on edge (gasp! horror! yea - I know) as would wider planks.

Option 2 does have a slightly smaller workbench, but in that case I'd build up the (top opening) enclosure for the chest freezer to the same level as the bench top effectively giving a bench almost the full length of the garage. (Possibly without dog-holes for the last part though, depending on which one of a few approaches I take)

The main difference between options 1 and 2 seem to be:

Option 1 allows things to hang off both ends of the bench.

Option 1 allows me to get around the end of the bench (by the end vise).

Option 1 allows things to hang off both ends of the bench.

Option 2 has potential for a longer "bench" when using the freezer cabinet top too.

I suppose Option 2 still provides a useful space on top of the freezer for putting things like grinders for sharpening chisels, irons, gouges and the likes.

Power tool storage will mostly be below the bench, though some may go in the cupboards if there's not enough space there. I've got to find a home for a bench-top bandsaw, a lathe, a table saw, a few grinders, a bench-top pillar drill, some hand power tools like sanders and so on. The table saw is on legs, but I expect I'll unscrew them, dump it all under the bench and just re-build the TS when I need it. It's FAR from ideal but I don't have enough space for ideal. I think I'll have enough space to store it all and though it means a complete pain-in-the-backside working method it's the best I can see for the space I have available.

Most likely I'll need to use the tablesaw outside on the driveway when it comes to things like 8x4 boards. I think things will be too cramped in the workshop to use a tablesaw and stand to the side for safety.

As I need the tools I'll most likely be taking them from under the bench and placing or clamping them on top, putting them on the freezer-cabinet or putting them on a "workmate" type thing I've got.

So - input please.

I'm after suggestions about which layout seems better (particularly which would make for a "better" bench) and any improvements you can suggest.

The wood storage can't be as wide as I would like, but can you suggest an "absolute minimum" if there is such a thing? I'd like to store as much as I can lying flat, but anything wide will have to go on edge.

A bit of a long post, thanks for reading and I look forwards to any replies you can give.