Jelly":1ej8126w said:

This may have been done before, but the search function doesn't bring much up.

What are the relative advantages of wooden and metal planes? I use both, but definitely prefer the wooden ones though in part that may be having been lucky to get a decent smoother, jack and try plane to start with. My Faithfull № 4 has been indispensable on this last project (never using purpleheart for fine joinery again!) as it was less of a big deal to sharpen a back-bevel for an increased cutting angle, as I knew the iron was an easily replaceable standard part.

I presume metal planes (especially steel planes, assuming they're not all either bargin basement, or collectable early stanley) would have an advantage for site work.

From the outside, I find it frustrating British woodworkers generally don't have an appreciation of their wooden plane heritage. In the 18th Century, when British planes were made by a local plane maker rather than by some larger factory the planes were the best ever made. At least I believe they were.

Take for example Rich's post in the thread on the history of left-handed tools:

richarnold":1ej8126w said:

As a lefty, and a lover of vintage tools, this has been a constant struggle over the years, but basically I have just learnt to adapt and use moulding planes and anything handed in the convetional manner with my right hand. The early bench planes had an offset handle and I made a big mistake a year or so ago when I made some copies of an early 18th century design. I forgot to reverse the offset!!. I just couldn't use them at all. I ended up selling them to an American tool dealer.

Rich found 18th Century style planes set up for right-handed use were unusable. I know exactly what he's talking about. But think about that for a minute. The off-set tote (yes, it's an old British term as is rabbet) makes that much difference in the side-to-side balance of the plane that Rich didn't keep those planes he made? It really does make that much difference, you feel like you're fighting the plane the whole time you're using it if the tote is off-set the wrong way.

Here's a question--if the plane makers of the time paid that much attention to the side-to-side balance of the plane, wouldn't they also pay attention to the end-to-end balance?

Given that the balance is most relevant on the return stroke and the return is more than half the work you do with a plane. I learned a long time ago to avoid dragging a tool, other project piece, or anything else across my work. This will leave a burnished scar on the surface that really leaps out on application of stain or surface film finishes. If you're going to avoid these burnished scars unexpectedly leaping out during the finishing process and spoiling the work, you need to develop the habit of never dragging anything across your work through the whole building process.

Can a plane be made so that it's easily lifted off the work with just one hand holding the tote? Yes and it can be made so that it naturally leaves the surface parallel in both the X and Y axis. I don't know of any metal planes made that way and Continental wooden planes are simply awful when it comes to balance. American wooden planes aren't much better than Continental planes.

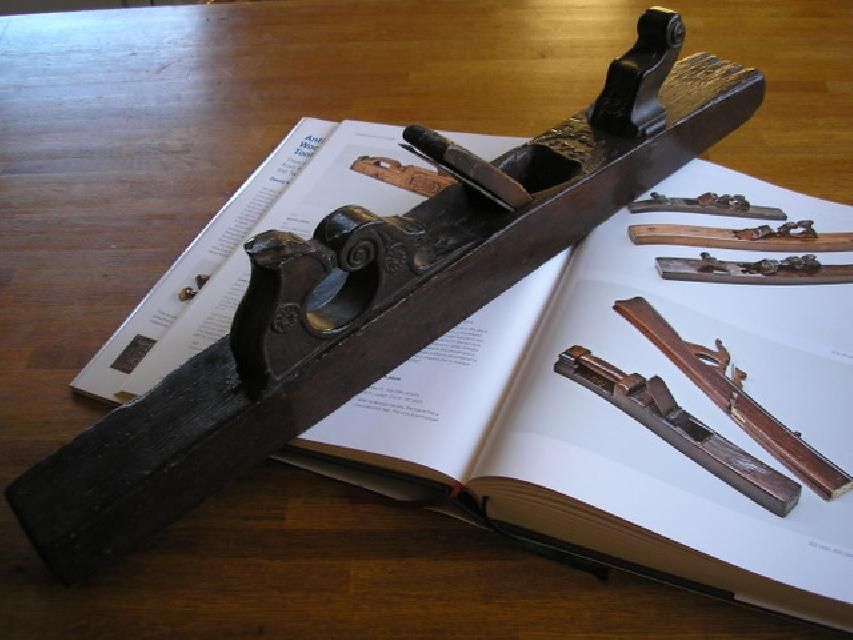

Here's a 30" 18th Century style British jointer that's balanced the way it can be. It's agile, less tiring and stressful to use, and feels like a natural extension of your arm.

Here's a photo of an early Stanley 608C that Stanley called a "jointer." No, it's a 24" trying plane as is the wooden plane just behind it and a true jointer just behind them.

The Stanley weighs 8 pounds 6 1/2 ounces, the wooden trying plane weighs 5 pounds 11 1/2 ounces, and the 30" jointer weighs 6 pounds 8 ounces. Given the poor balance of the Stanley it feels like it's actually more than twice as heavy as the wooden jointer. After working with planes they way they can be, I now find the Stanley as unusable as Rich found his right-handed planes.

As to adjusting, I find adjusting a wedge-set single iron wooden plane a lot easier and faster than Stanley's adjustment gimmick. Properly made wooden planes will make bench work a lot easier for anyone who's willing to take a few minutes to set them.