Sawdust=manglitter

Established Member

I looked at this project as an excuse to get in some practice at more curvy/sculptural type work. So I sketched some designs for the feet. Once happy with the shape I drew it full size and accurate, using some French curves to refine the sweeping curves.

Once drawn properly on paper I then cut them out and stuck onto MDF to make the template. This was the cut out template...

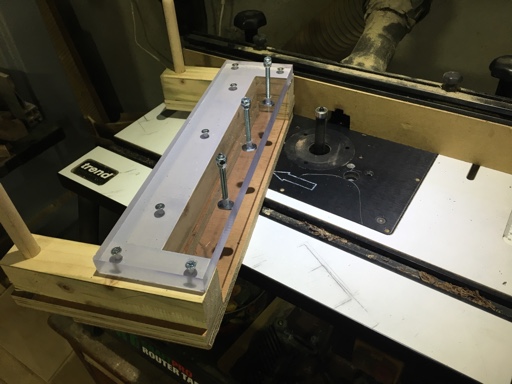

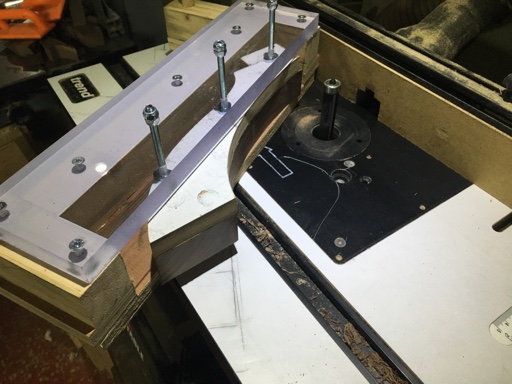

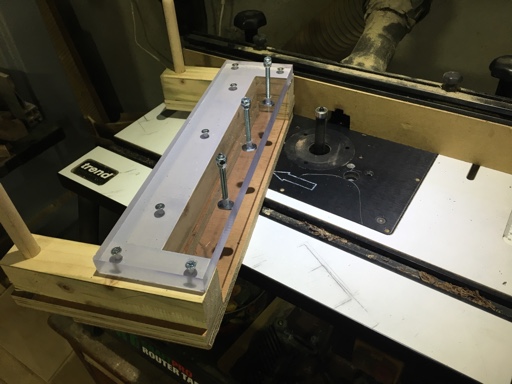

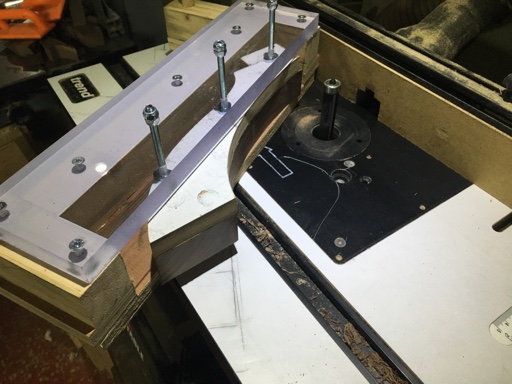

I originally intended on making three sets of legs, but having had a bit of a twitchy bum moment and a catch with one of the legs which got thrown to the floor (and broke!!) I mad a much needed jig holder thing for smaller pieces on the router table...

These are the freshly cut legs...

Not got loads of photos every step of the way sorry.

Once in this state with square corners I cut a half lap joint which needed a curved profile for as good a fit as I could manage before shaping etc. Once glued I used a round over bit to roughly shape the corners, cleaned up a bit with chisels and lots of hand sanding. Following the hand sanding I did what I could to buff them up on the buffing wheels. One mostly buffed, the other not done yet...

More photos etc will follow when I get more time later on

Once drawn properly on paper I then cut them out and stuck onto MDF to make the template. This was the cut out template...

I originally intended on making three sets of legs, but having had a bit of a twitchy bum moment and a catch with one of the legs which got thrown to the floor (and broke!!) I mad a much needed jig holder thing for smaller pieces on the router table...

These are the freshly cut legs...

Not got loads of photos every step of the way sorry.

Once in this state with square corners I cut a half lap joint which needed a curved profile for as good a fit as I could manage before shaping etc. Once glued I used a round over bit to roughly shape the corners, cleaned up a bit with chisels and lots of hand sanding. Following the hand sanding I did what I could to buff them up on the buffing wheels. One mostly buffed, the other not done yet...

More photos etc will follow when I get more time later on