Okay, have been able to steal chunks of time over the last week and make some progress. My next job was to mark up the mortices, made sure I checked from the glued up legs rather than the plan, to allow for any deviation, there was some but not much.

My attempt to drill out most of the waste was thwarted by my cheap Clark forstners, I've always thought that sycamore is a softer hardwood, my experience on this piece is that it's about as hard as maple, ie very. So out with router to freehand the waste from the middle.

This worked fine but left far too much waste to pare away as I was losing the will to live. So made a template to use with a smaller bit, this would leave much less paring

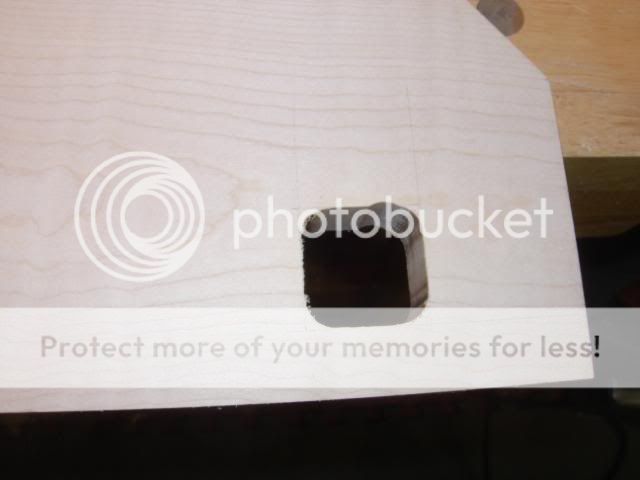

All was going well until the template slipped, was it on the back, no, of course it wasn't, it was on the front...

There's a nick out, not too big and I'll until the leg is in before deciding what to do about it. Added another clamp

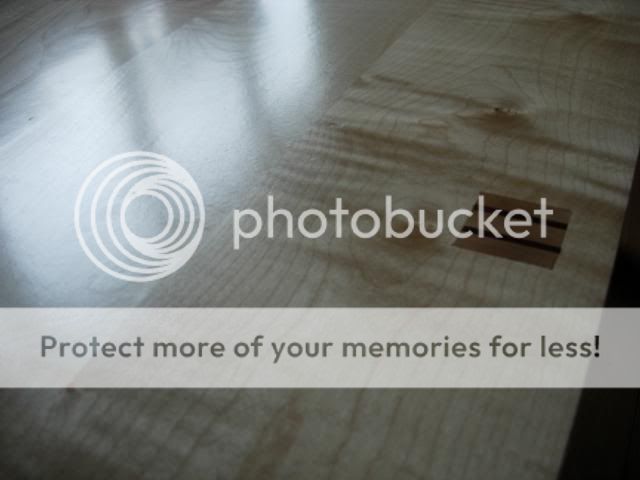

Here are the finished mortices, the paring to fit after routing took all of the afternoon football on Saturday. My hands are mincemeat but on the bright side, Up the Villa

Went for a steep angled chamfer on the edges eventually, hopefully will blend in the curve of the legs. Once again there wasn't a router bit to fit and I didn't fancy attempting it on either saw. So out with the handplanes, slight gloatage again but both planes were well used. Mincemeat hands now burger meat

Back to the legs, bit of masking tape on the glue areas to protect from the finish

Which is this, a spray lacquer. Never used one before so a bit of a leap into the unknown. Having used rattle can spray paint before I know that a mask is essential, this is one of Screwfix's finest chemical masks, works a treat.

Legs received all bar the final coat before attaching to the top. Look good so far though. Cut the tenon slots on the bandsaw, marked up a line and then cut just either side of it to have accuracy and a wide enough slot

Dug out a bit of walnut and marked roughly the wedge width, before bandsawing

Initially got out the sandpaper to shape and fit each wedge to the slots. Approximately 48 seconds later realised that this was a bad idea and moved on to the power sander. Worked well and only re-profiled my fingertips a couple of times

As I had fitted them individually to their slots I decided I could do without any more stress at glue up, so marked up where they were going to go once I took them out

Finally onto glueing the legs in, fairly painless (unlike the dovetail keys) and inserting the wedges went well and it was most satisfying to drive them home with a solid twatting from the mallet. Here the legs have been rubbed down to accept their final coat and the top has no finish at all yet

Pressure is on to get the finish on so I can take it to the glaziers

/