andy king

Established Member

Hi BigShot,

It shouldn't be a problem with the short grain if the unit isn't being moved, it's simply good practice to avoid short grain situations if possible.

Don't make the joint so tight that it has to be hammered in, that will likely break it away - a little bit of play to allow it to swell slightly as the weather changes may help prevent it splitting away as well, but a joint that fits well by hand pressure alone should be your aim in any joinery work.

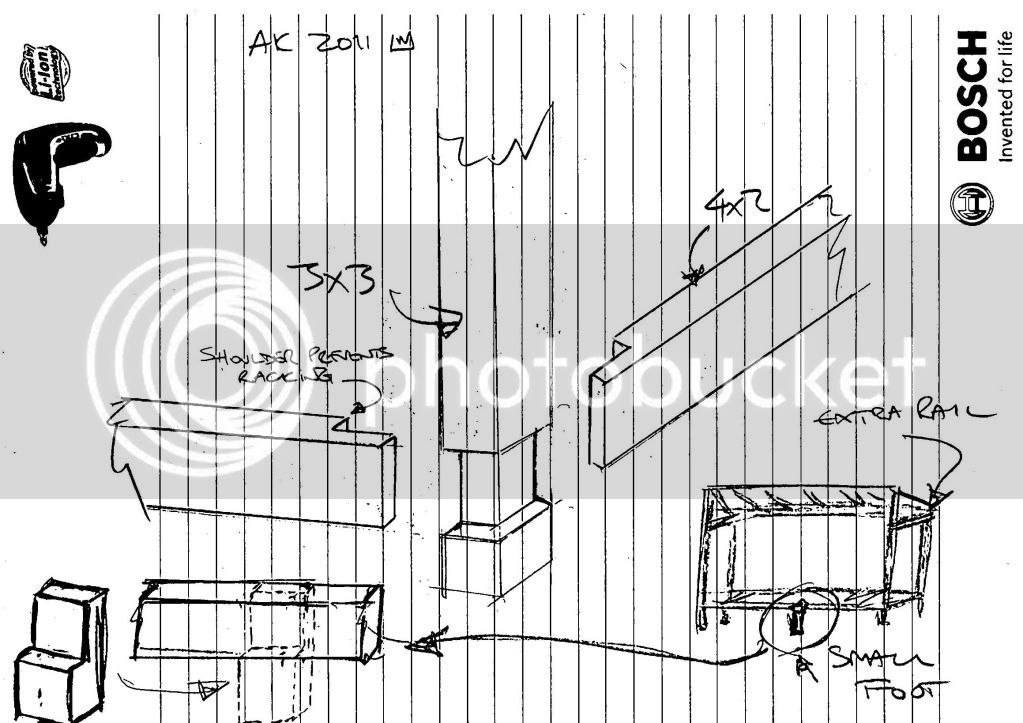

I would stick with 3x3 posts for the legs, that's more than man enough for the job, but if you choose to go for 4x2 as rails you have increased strength, plus you can now introduce a shoulderline and that immediately helps stiffen the framework and minimse racking.

If you are concerned about the frame deflecting in the middle, a stub leg will solve that problem.

Give me 10 mins and i'll do a sketch and scan it in - hopefully that may make more sense then...

cheers,

Andy

It shouldn't be a problem with the short grain if the unit isn't being moved, it's simply good practice to avoid short grain situations if possible.

Don't make the joint so tight that it has to be hammered in, that will likely break it away - a little bit of play to allow it to swell slightly as the weather changes may help prevent it splitting away as well, but a joint that fits well by hand pressure alone should be your aim in any joinery work.

I would stick with 3x3 posts for the legs, that's more than man enough for the job, but if you choose to go for 4x2 as rails you have increased strength, plus you can now introduce a shoulderline and that immediately helps stiffen the framework and minimse racking.

If you are concerned about the frame deflecting in the middle, a stub leg will solve that problem.

Give me 10 mins and i'll do a sketch and scan it in - hopefully that may make more sense then...

cheers,

Andy