After a good rummage in the nuts and bolts box I found a hacksaw bolt and thumbscrew which when paired up with a bolt and brass wing nut I thought would be ideal:-

Well the hacksaw bolt migt have been a good ideal if I had drilled the large hole on the right side

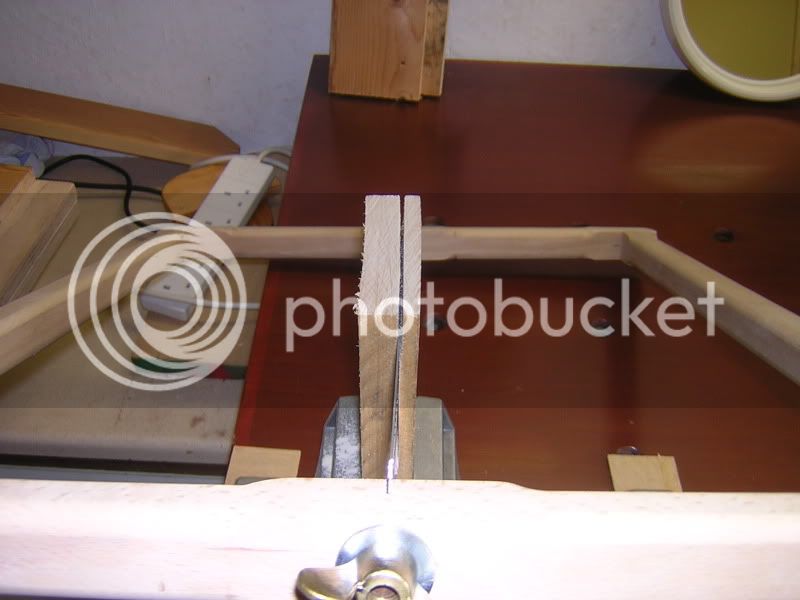

The slot is there so the blade does not twist when tightening or in use.

In reality what seemed like a good idea was not. The hack saw bolt was too short and the large hold required weakened the frame too much when the blade was tensioned.

So out came my variable speed lathe

and along with the only turning tool I own I made a plug

Which seemed to fit quite well

A new longer bolt was fashioned. By being able to adjust the blade at each end I reasoned that it would be easier to keep the blade upright

The finished saw

Of course any tool is only as good as it performs

I am reasonably pleased with the result. I think the frame needs to be thicker, at least wider than the blade itself so as the blade does not touch the bench when it is laid down.

It also seems quite hard to exert downward pressure while sawing. Perhaps it shouldn't be necessary? I'll put this down to technique although I think I would like to try a t thinner Japanese pul saw blade. Blade came from

http://www.fine-tools.com/gestell.htm

Cheers

Andy