thetyreman

Established Member

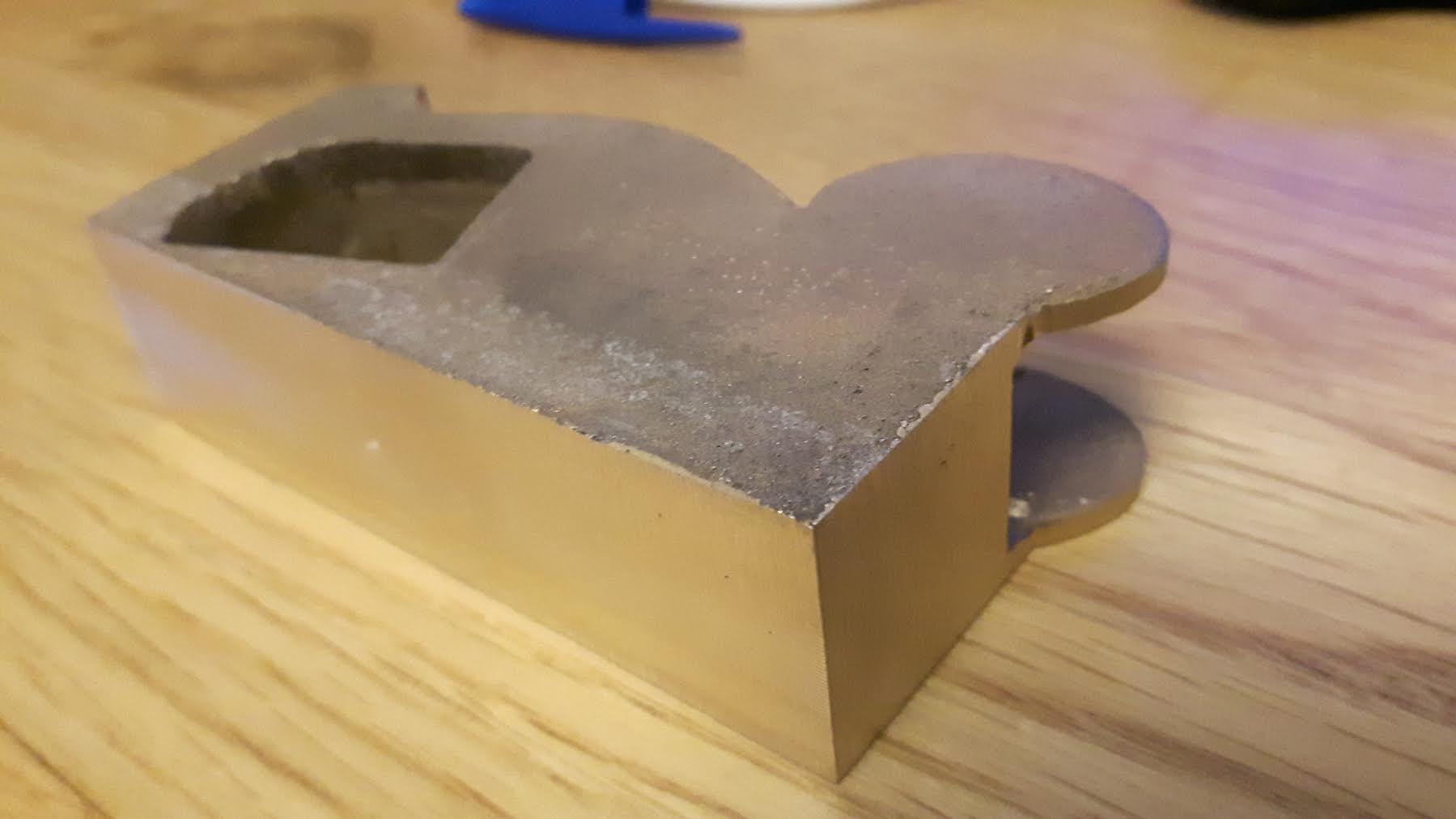

MattRoberts":4hlyonpj said:Nice - I did the same. I also modified the screw component. I found that if I tightened them up, they would shear off the silver screw that fits into the Grove at the end of the clamp head screw.thetyreman":4hlyonpj said:retofitted all my cheap clamps with wood, using 2x1 pine (cut to size), now they really feel quite solid:

What I did was undo it all, pop a small nut loose in the receiving hole of the clamp head and then do it back up again. The loose nut closes the gap, so the clamping pressure isn't all put on the silver screw.

thanks for the tip, I've already had problems with them falling off on a couple of them, so just for clarity, you mean the actual blue clamp head? on the black screw thread, put the nut inside there? cheers