boysie39

Established Member

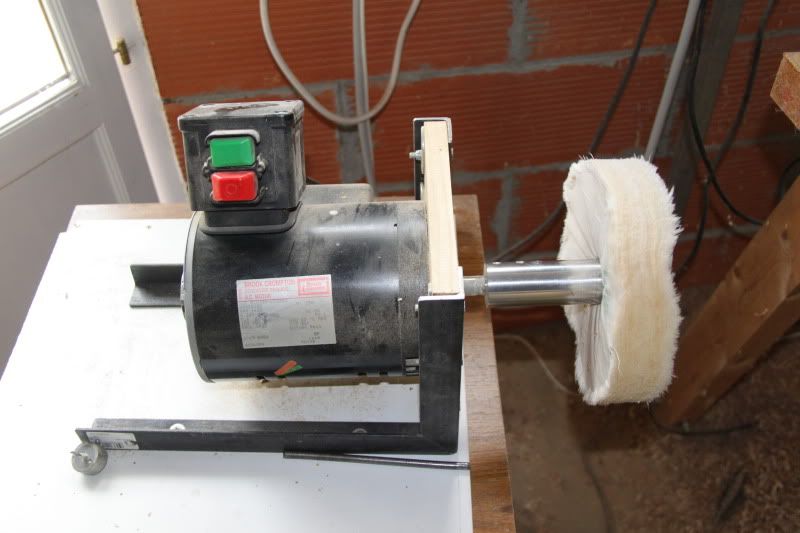

I was wondering what way you turners that have buffing wheels set them up for useing.

I read on another forum where some have the three wheels mounted on a shaft that is

set up between centers on the lathe. Questions

What do you use and

what way do you set it up if any.

I have never used any buffing system so look fwd. to your advice.

Can finishes such as Woodwax ,Microcrystelian or whatever be applied with buffing wheels .

How to get the best results with buffing wheels :?: :?: .

I read on another forum where some have the three wheels mounted on a shaft that is

set up between centers on the lathe. Questions

What do you use and

what way do you set it up if any.

I have never used any buffing system so look fwd. to your advice.

Can finishes such as Woodwax ,Microcrystelian or whatever be applied with buffing wheels .

How to get the best results with buffing wheels :?: :?: .