tool613

Established Member

there are two guards on a modern jointer. There is the stander pork chop/bridge and what I will call the back guard that covers the head when the fence is move over the table. Most old jointer don,t have the main and very little have a back guard.The wakin RM never had the back guard and so I made one.

the machine as i got it.

A safety guard has to do 3 things to be of any use.

1 The most important is protect the operator from the cutter head.

2 be easy to adjust and not be in the way of the machines function as it was designed to preform.

3 be easy to remove for assess to the cutter head.

it can than look good if you want .

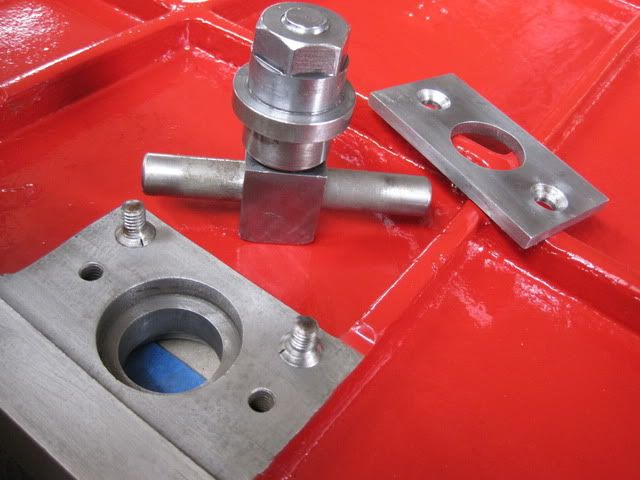

I have 26" of head to cover at any given time and I wanted to be able to adjust while the machine was running. Most back guards are attached to the fence and so I designed mine to do the same. I simply welded a simple rod and bracket that screwed in taped holes to the fence base for my guard to attach.

Because the table slide in and out to open the cutter block for moulding my guard needed this adjustment as-well.

I made it from aluminum and copper to keep it light but strong.

adjustment for sliding in and out

fully extended to 26"

fence tip 45 drgs

jack

the machine as i got it.

A safety guard has to do 3 things to be of any use.

1 The most important is protect the operator from the cutter head.

2 be easy to adjust and not be in the way of the machines function as it was designed to preform.

3 be easy to remove for assess to the cutter head.

it can than look good if you want .

I have 26" of head to cover at any given time and I wanted to be able to adjust while the machine was running. Most back guards are attached to the fence and so I designed mine to do the same. I simply welded a simple rod and bracket that screwed in taped holes to the fence base for my guard to attach.

Because the table slide in and out to open the cutter block for moulding my guard needed this adjustment as-well.

I made it from aluminum and copper to keep it light but strong.

adjustment for sliding in and out

fully extended to 26"

fence tip 45 drgs

jack