You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

unusual profile

- Thread starter SteveF

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

nev

Established Member

bobham

Established Member

I think I would glue up a 5.25" x 5.25" square 36" long and cut the step profile on a table saw while the blank was still square. Then glue in filler pieces using paper in the joints to make it square again. Then mount it on the lathe and turn it into a 5" round, splitting the paper joint apart once it was done and cutting to final length to produce the finished piece. If the final profile needs to be accurate you will need to be very precise in making the center dimples for the drive and tail centers to produce the required shape. It _might_ be possible to cut the profile and then simply mount the piece off center to turn to round, skipping the filler pieces, but if you are not a _very_ experienced turner (and, really, even if you are) I think having the filler pieces would be more likely to produce better results since it would be a continuous cut rather than an interrupted cut.

Here is a link to a Youtube video of the split turning technique. The glue joint would be the same but yours would be off center.

http://www.youtube.com/playlist?list=PL ... IKeaBkkviV

Good Luck!

Bob

Ahh! I see Nev types faster than I do...

Here is a link to a Youtube video of the split turning technique. The glue joint would be the same but yours would be off center.

http://www.youtube.com/playlist?list=PL ... IKeaBkkviV

Good Luck!

Bob

Ahh! I see Nev types faster than I do...

You don't need a lathe, just a bench plane.

From square stock, glue up pieces, forming the square rebate as you go. Draw the section on both ends.

Clamp the rebated part in the vice and plane the angles off, approaching the circle as you go. For something quite big (5" dia) you don't even need a hollow plane.

Finish off by sanding.

From square stock, glue up pieces, forming the square rebate as you go. Draw the section on both ends.

Clamp the rebated part in the vice and plane the angles off, approaching the circle as you go. For something quite big (5" dia) you don't even need a hollow plane.

Finish off by sanding.

chipmunk

Established Member

I think I'd be tempted use a bit of Bob's response and a bit of Andy's...

Create the square rebate with two sections (one simply offset), glued permanently together.

I don't think I'd even bother with the filler piece in the rebate unless you experience real trouble with your lathe bouncing around and even then I'd just use nev's suggestion of a couple of large tie-wraps or tape at the ends to keep the filler in-place.

Before turning I'd roughly plane off the corners to ease the roughing out and then turn the item round with a spindle roughing gouge and then finally use a bench plane to put the flat on the side.

HTH

Jon

Create the square rebate with two sections (one simply offset), glued permanently together.

I don't think I'd even bother with the filler piece in the rebate unless you experience real trouble with your lathe bouncing around and even then I'd just use nev's suggestion of a couple of large tie-wraps or tape at the ends to keep the filler in-place.

Before turning I'd roughly plane off the corners to ease the roughing out and then turn the item round with a spindle roughing gouge and then finally use a bench plane to put the flat on the side.

HTH

Jon

bellringer

Established Member

I would take a square block rip the piece you don't want out then turn it should be fine

£16.59

£25.00

Woodworking Joinery by Hand: Innovative Techniques Using Japanese Saws and Jigs

Amazon.co.uk

£19.99

Respirator Mask,Safety Dust Face Cover,Dust Face Cover Paint Face Cover,Gas Mask With Filter,For Paint,Dust And Formaldehyde,Sanding,Polishing,Spraying And Other Work

ShenZHEN CIRY MINGYANG LITIAN ELECTRONIC ECOMMERCE

£238.91

£360.17

Trend Portable Benchtop Router Table with Robust Construction for Workshop & Site Use, 240V, CRT/MK3

Amazon.co.uk

£12.50 (£1,250.00 / kg)

£14.45 (£1,445.00 / kg)

JSP M632 FFP3moulded Disposable Dustmask (Box of 10) One Size suitable for Construction, DIY, Industrial, Sanding, dust protection 99 Percent particle filtration Conforms and Complies to EN 149

Amazon.co.uk

£17.99 (£1.80 / count)

£27.44 (£2.74 / count)

3M 8822 Disposable-fine dust mask FFP2 (10-pack)

Amazon.co.uk

£24.99

Facemoon Reusable Masks,Safety Masks,Dual Filter Masks, Paint, Dust, Epoxy Resin, Construction, Welding, Sanding, Woodworking, Chemical Reusable Gas Masks

ShenZHEN CIRY MINGYANG LITIAN ELECTRONIC ECOMMERCE

Dalboy

Established Member

This is assuming that you have a router table.

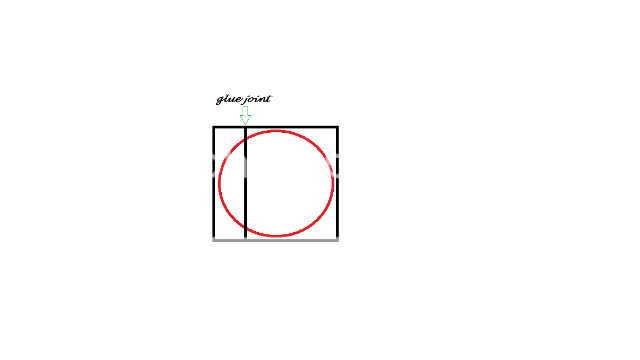

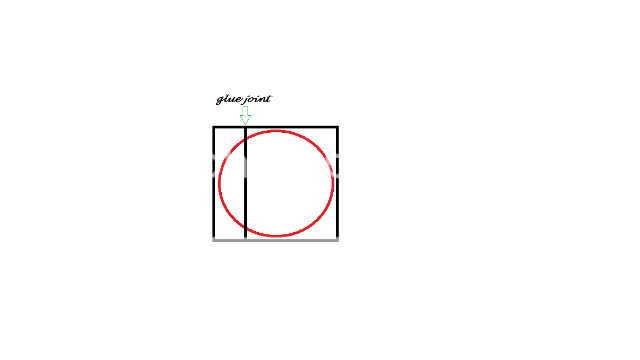

Make up a square section from two pieces longer than the length that you need as in the diagram using a paper glue joint, glue joint at the measurements that you require

Once rounded split the two pieces apart. using a router table place the flat on the table and run the curved part along the fence and rout our the step as required.

Hope this makes sense. this is how I would do it as I have a largish router table

Make up a square section from two pieces longer than the length that you need as in the diagram using a paper glue joint, glue joint at the measurements that you require

Once rounded split the two pieces apart. using a router table place the flat on the table and run the curved part along the fence and rout our the step as required.

Hope this makes sense. this is how I would do it as I have a largish router table

MMUK

Established Member

I assume this is some kind of handrail profile?

Personally, I'd just glue and biscuit the timber. Then I'd chamfer the edges and turn it on the lathe to the diameter you want. Then I'd run it through the table saw to create the flat on the left, mount it and rout out the rest.

Personally, I'd just glue and biscuit the timber. Then I'd chamfer the edges and turn it on the lathe to the diameter you want. Then I'd run it through the table saw to create the flat on the left, mount it and rout out the rest.

Jacob

What goes around comes around.

Ditto. Much easier than turning. In fact you don't need a hollow plane for anything convex, large or small, though they can help with smaller profiles.AndyT":1cdc3cfk said:You don't need a lathe, just a bench plane.

From square stock, glue up pieces, forming the square rebate as you go. Draw the section on both ends.

Clamp the rebated part in the vice and plane the angles off, approaching the circle as you go. For something quite big (5" dia) you don't even need a hollow plane.

Finish off by sanding.

I took AndyT and Jacob advise......sort of

decide not to glue extra pieces on

I thought i would just mount up an turn between centers

after my lathe shaking like mad and then throwing the timber at me :x

I got a #4 clamped the lump and proceeded to hand plane

took me a good few hours but they are close to being round

I need to fill a few bits and get the sander out but am pleased with result

the extra pieces glued on paper was really the better option I guess

thankyou everyone for their advise given ....i will know next time

Steve

decide not to glue extra pieces on

I thought i would just mount up an turn between centers

after my lathe shaking like mad and then throwing the timber at me :x

I got a #4 clamped the lump and proceeded to hand plane

took me a good few hours but they are close to being round

I need to fill a few bits and get the sander out but am pleased with result

the extra pieces glued on paper was really the better option I guess

thankyou everyone for their advise given ....i will know next time

Steve

Similar threads

- Replies

- 17

- Views

- 755

- Replies

- 6

- Views

- 880