Hi all,

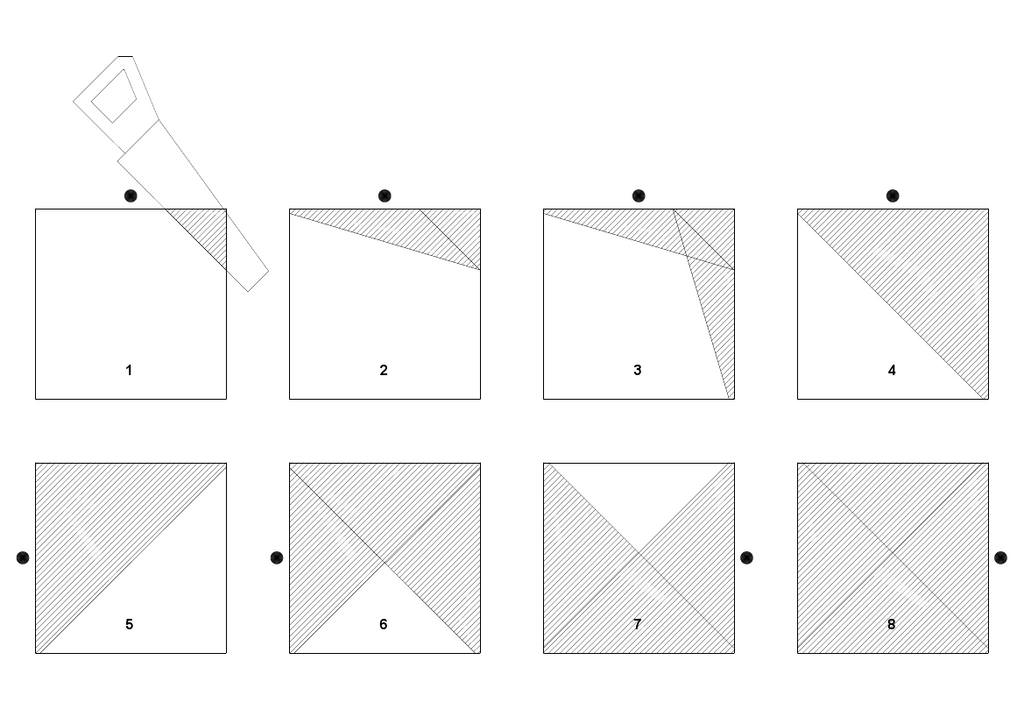

I admit my sawing isn’t the best, but today I actually realised that I have a slight lean to the right which no matter how hard I try I just couldn’t shift.

My wife has told me to just keep practising but I had an issue where I needed to shave 1mm off the end of a piece of 2x2 but I ended up shaving 1mm where I first started my cut but by the bottom I trimmed 2mm, not ideal.

Am I right in thinking that a block plane would have been the right tool for the job to take that 1mm off? I am on about across the grain as well if that makes a difference with the tool.

Thanks.

H

Sent from my iPhone using Tapatalk

I admit my sawing isn’t the best, but today I actually realised that I have a slight lean to the right which no matter how hard I try I just couldn’t shift.

My wife has told me to just keep practising but I had an issue where I needed to shave 1mm off the end of a piece of 2x2 but I ended up shaving 1mm where I first started my cut but by the bottom I trimmed 2mm, not ideal.

Am I right in thinking that a block plane would have been the right tool for the job to take that 1mm off? I am on about across the grain as well if that makes a difference with the tool.

Thanks.

H

Sent from my iPhone using Tapatalk