Ihaveadream

Member

Hi Everyone,

I am an absolute beginner to woodworking and hope to make a sturdy 2000mm x 1600mm x 600mm cabinet on casters that will hold heavy equipment.

Short question is:

Is the edge grain of plywood still classed as long grain for gluing purposes.

The reason im asking:

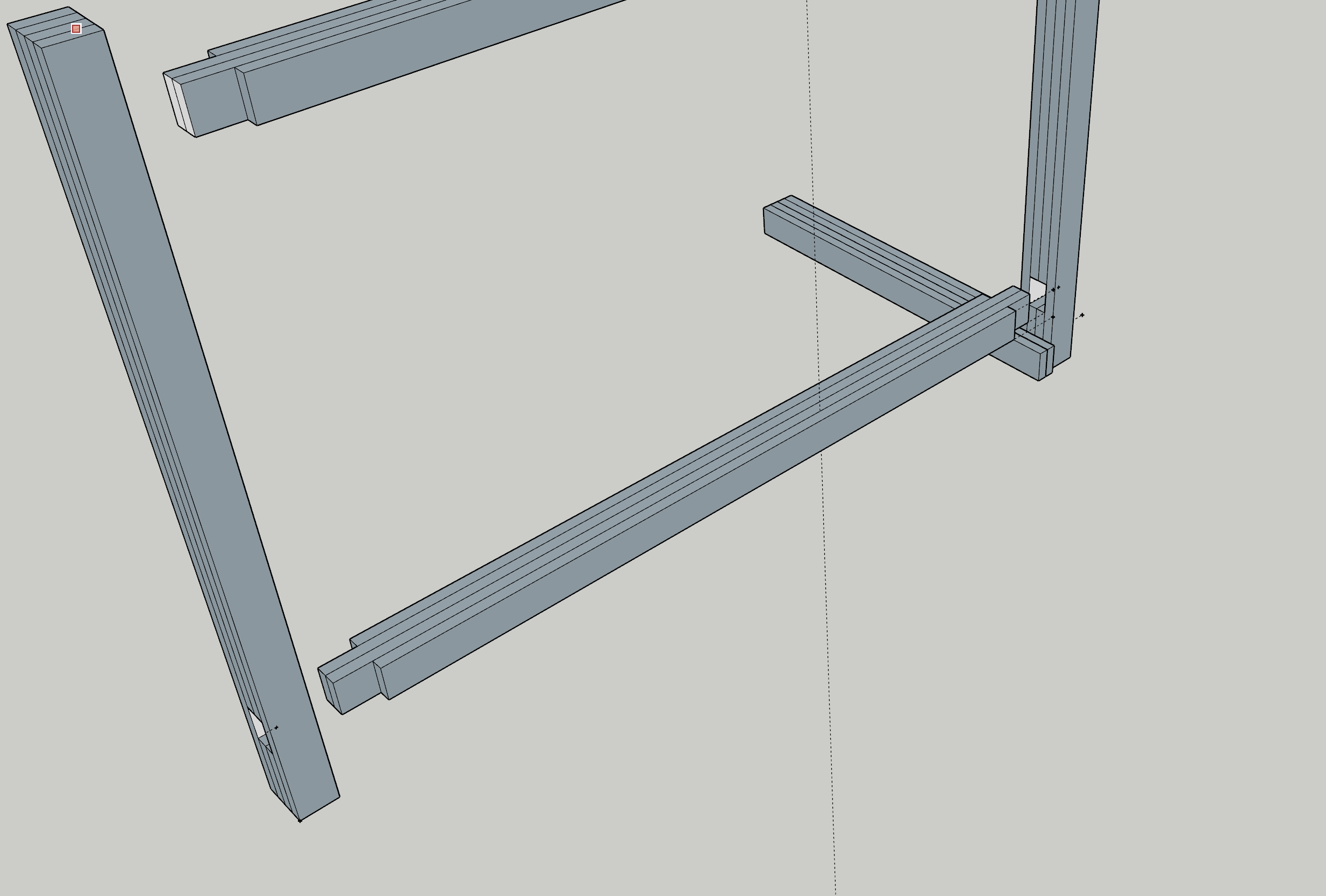

I plan to just use glue and a saw for my cabinet. Im going to try and make mortice and tenons by gluing 4 x 6mm plywood planks together and cutting the two middle planks longer to make the tenon.

These planks will be the 1600mm pieces.

Then cut a section out of the middle two of another 4 planks and gluing them together leaving space for a through tenon in the 2000mm tall piece. Thats how i want to construct the front and back of the cabinet.

But to join the front and back pieces together i wanted to do a half lap joint by leaving the outer two of a 4 plank glue up longer and then gluing the exposed faces to the edge grain of the joint that has the mortice in it. I know if i screw into this i risk separating the ply sheets so im wondering if a glue joint, face to edge grain will hold and be strong enough to hold the front and back together.

Sorry for the extremely long post hopefully you can visualise what I mean.

I am an absolute beginner to woodworking and hope to make a sturdy 2000mm x 1600mm x 600mm cabinet on casters that will hold heavy equipment.

Short question is:

Is the edge grain of plywood still classed as long grain for gluing purposes.

The reason im asking:

I plan to just use glue and a saw for my cabinet. Im going to try and make mortice and tenons by gluing 4 x 6mm plywood planks together and cutting the two middle planks longer to make the tenon.

These planks will be the 1600mm pieces.

Then cut a section out of the middle two of another 4 planks and gluing them together leaving space for a through tenon in the 2000mm tall piece. Thats how i want to construct the front and back of the cabinet.

But to join the front and back pieces together i wanted to do a half lap joint by leaving the outer two of a 4 plank glue up longer and then gluing the exposed faces to the edge grain of the joint that has the mortice in it. I know if i screw into this i risk separating the ply sheets so im wondering if a glue joint, face to edge grain will hold and be strong enough to hold the front and back together.

Sorry for the extremely long post hopefully you can visualise what I mean.