MikeG.

Established Member

I bought some seasoned (French) oak boards, and planed most of it up on a friend's wide planer/ thicknesser:

Some of the boards were too wide even for his monster machine:

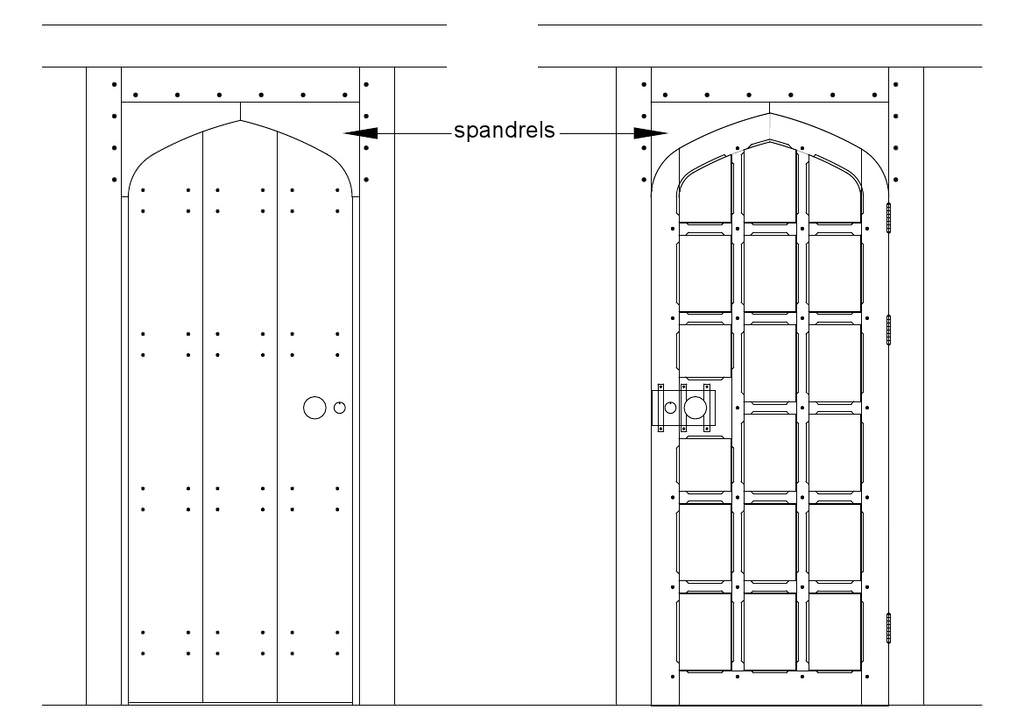

This is for three doors: the external front door (porch door), the internal front door, and the downstairs loo door. I started with the outside front door. Before I could start work on the door itself I had to make the 4-centred arch door head, which is done with a pair of spandrels. First, a template:

That last photo shows the long mortices I left when I made the porch last year. Now, with a wedding coming up in no time at all, I needed to make the spandrels, but I wouldn't have time to carve them, so they'll have to be removable for carving later. I had set aside a large piece of green oak from the porch build, but as it was over a year old it wasn't quite so green any more:

Big as it was, it wasn't big enough to do the spandrels in one piece a side, so I had to glue on an extra bit:

Marking up the template on the door opening revealed no surprises at aLL..........the timbers weren't straight:

To cut the long shoulder of the top mortice I clamped a guide-piece to the spandrel and just sawed. There are a number of other ways this could be done:

Hogging off the waste:

A bit of wax to help it into place:

And the first trial fit:

It needed a whack or two with a rubber mallet, but went in rather well.

The second one was always going to be more awkward, because the first one is ion the way. I shaped the tenon:

The butt joint in the middle is obviously never going to be weather-tight:

So my solution was to add a groove to each piece:

And in due course I shall whack in a sliding tenon. Of course, that can't happen until the spandrels have been completely finished and carved, because they won't be removable after the loose tenon is fitted.

And so to the door.........

Some of the boards were too wide even for his monster machine:

This is for three doors: the external front door (porch door), the internal front door, and the downstairs loo door. I started with the outside front door. Before I could start work on the door itself I had to make the 4-centred arch door head, which is done with a pair of spandrels. First, a template:

That last photo shows the long mortices I left when I made the porch last year. Now, with a wedding coming up in no time at all, I needed to make the spandrels, but I wouldn't have time to carve them, so they'll have to be removable for carving later. I had set aside a large piece of green oak from the porch build, but as it was over a year old it wasn't quite so green any more:

Big as it was, it wasn't big enough to do the spandrels in one piece a side, so I had to glue on an extra bit:

Marking up the template on the door opening revealed no surprises at aLL..........the timbers weren't straight:

To cut the long shoulder of the top mortice I clamped a guide-piece to the spandrel and just sawed. There are a number of other ways this could be done:

Hogging off the waste:

A bit of wax to help it into place:

And the first trial fit:

It needed a whack or two with a rubber mallet, but went in rather well.

The second one was always going to be more awkward, because the first one is ion the way. I shaped the tenon:

The butt joint in the middle is obviously never going to be weather-tight:

So my solution was to add a groove to each piece:

And in due course I shall whack in a sliding tenon. Of course, that can't happen until the spandrels have been completely finished and carved, because they won't be removable after the loose tenon is fitted.

And so to the door.........