That's a friggin' crime. The price isn't bad, but I'd cut off the hand drill and leave it lying on his floor as I drove away with the rest.

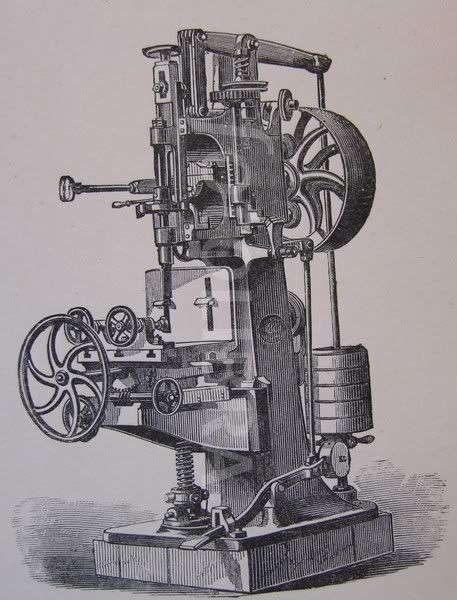

I seriously doubt that was a solid chisel mortiser to begin with. Those were almost always foot, not arm, powered so you could get a more powerful stomp on them. Also, that's a pretty massive casting for the solid chisel mortiser era. Once chain mortisers and hollow chisel mortisers came out, they displaced the solid chisel ones pretty quickly (for obvious reasons). This probably had another head on it back in the day.

Kirk