Ivan was a little ambiguous when he said

the camber will match that of the template about as well as a jig ground straight blade will match a square

.

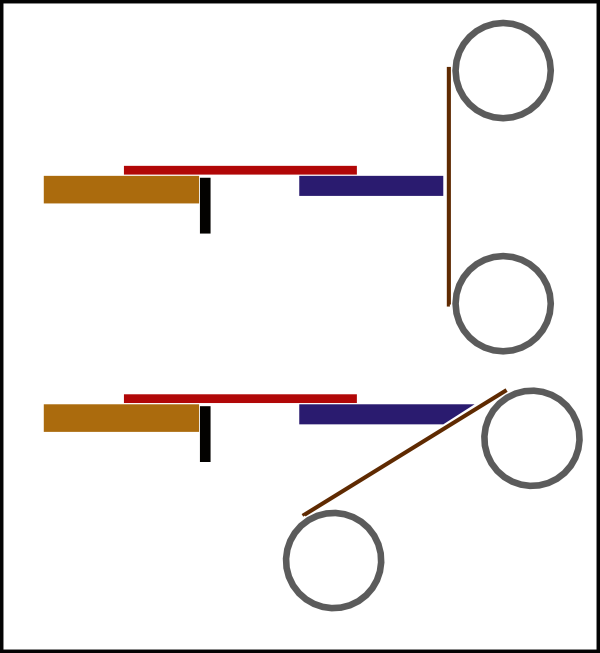

When the abrasive is wider than the blade, the edge can be very straight. With Derek's wide abrasive belt, he can put straight edges on very wide blades.

However, when the abrasive is narrower than the edge, there are problems. Notice that working a rounded edge with a flat abrasive always falls into this category. I used to grind with a 1" belt. I noticed that I could not get a really good ground edge no matter how careful I was to work steadily and carefully. That is one of the reasons I switched to a wide bench stone.

Forgetting the jig and getting back to the original post, we can split the problem into two parts -- preparing the iron, using the iron.

What can we say about preparing the iron? Until the iron goes into the plane, there is really nothing in its preparation that is affected by whether it is used bevel down or bevel up. If we can camber a bevel down iron, we can camber a bevel up iron.

It has been observed, correctly I think we can agree, that blades bedded at 12 degrees require about 3.4 times the curvature of blades bedded at 45 degrees. So, it comes to a question of degree. Can we sharpen to a smaller curvature. This is really only a problem for the extreme curvature of an iron used for scrubbing. In my experience, with radii from 6" to 3" there is not a lot more difficulty. Find a stance that lets you work through the full range of motion, practise a couple of times with the blade just off the abrasive, use light passes, ... Grinding is not much of an issue. Honing might be, but if you can hone a bevel down scrub iron you should be able to do a more extreme curve.

That leaves us with the problems during use. With 3.4 times the curvature for an equivalent use: Is there more effort? Is there faster edge wear? Is there a surface quality effect?

On surface quality, I suspect that most of the experience with surface quality and cambered blades comes from using hollows and moulding planes. There the geometry of the corners of the blade make it a scraper rather than a plane, resulting is degraded surfaces. These are final use planes - unless you sand after them. The scrub is not a final use plane, so surface quality cannot be an issue. On the much smaller radii of the jack and try planes, I would not expect it to be a problem (it is not on the corresponding moulding planes).

So, we are left with effort and edge durability as issues.

Anyone ready to try to compare the two? I might try to set up a bit of a test in the next couple of weeks. Can't be the same blade in the same plane, but something might be possible.

Brent

[Who really did not want to drag this thread out but noticed the "about as well" in Ivan's post, which is ambiguous, probably intentionally, so had to give the can one more kick and then got a little long winded.]

[Who hopes the connection stays up during submit of this second attempt. This first attempt had some comments about preparation which I hoped would not restart the discussion, but I cannot remember them now. I don't think further discussion of the grinding jig is necessary - it works.]

) but the template is also doing its work to create a specific camber.