jimi43

Established Member

Thanks for the clarification Richard...and I have spent many an hour when I should have been a-kip...working my way through your most excellent website...

If anyone is interested...Richards website can be found HERE

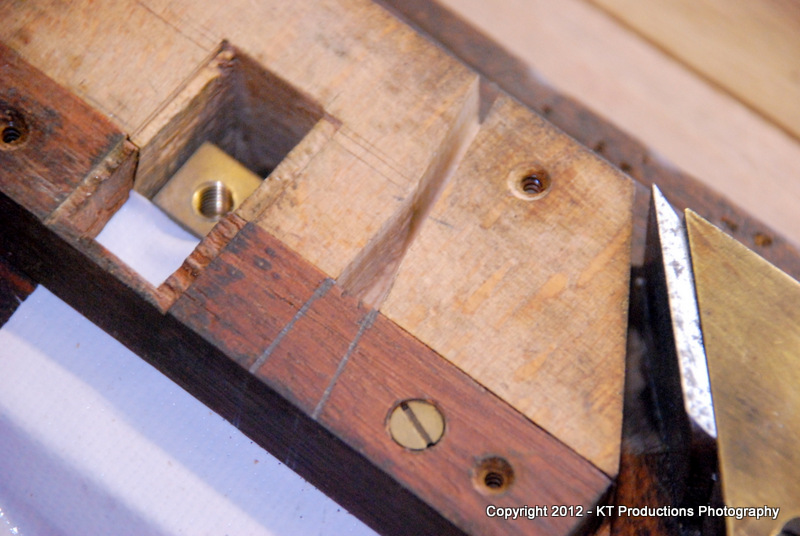

On the subject of the fence...I am going to spend a lot of time on here and trawling the research sites...to get the proper information before I decide to add a fence to this old lady. I want to make sure that I can do it justice...I want to get it back working again...clearly it had a small fence simply tacked on to do one job....and I would dearly love to make it adjustable.

To do this with a pre-War Stanley is one thing...to attempt it with something I happen to revere...is something quite different and will take a bit of guts before I even consider whether to embark on it.

Jim

If anyone is interested...Richards website can be found HERE

On the subject of the fence...I am going to spend a lot of time on here and trawling the research sites...to get the proper information before I decide to add a fence to this old lady. I want to make sure that I can do it justice...I want to get it back working again...clearly it had a small fence simply tacked on to do one job....and I would dearly love to make it adjustable.

To do this with a pre-War Stanley is one thing...to attempt it with something I happen to revere...is something quite different and will take a bit of guts before I even consider whether to embark on it.

Jim