Worthtrying

Member

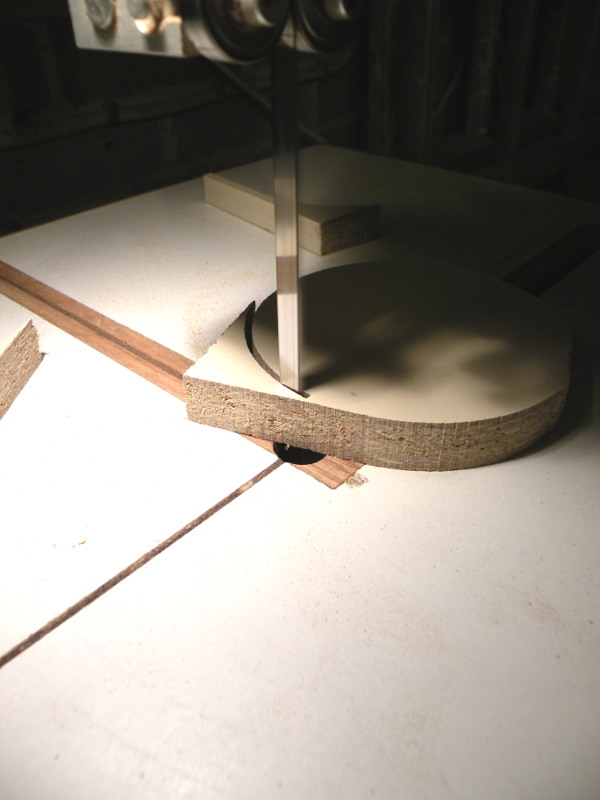

Hi everybody, as a virgin member, this is my first foray on the UKW Forum. My problem is regarding my Startrite 351 bandsaw, with which I'm trying to cut 38mm thick oak discs (worktop offcuts) in sizes ranging from 100mm - 400mm diameter. Surface finish isn't important in this instance as they're just rough blanks for woodturning. I'm using 3/8" wide x .025", 6TPI skip-tooth blades without much success. The motor labours, the wood smokes, & eventually the switch trips off. I can resume work after a couple of minutes but usually with the same results. I'm assuming that the task I'm trying to carry out is within the capacity of the machine but would like to here from any other 351 owners who might have experienced similar problems. I'm also considering ordering a couple of 3TPI skip-tooth blades but any advice or suggestions from other UKW members would be much appreciated.

Thanks

Thanks