Andrewf

Established Member

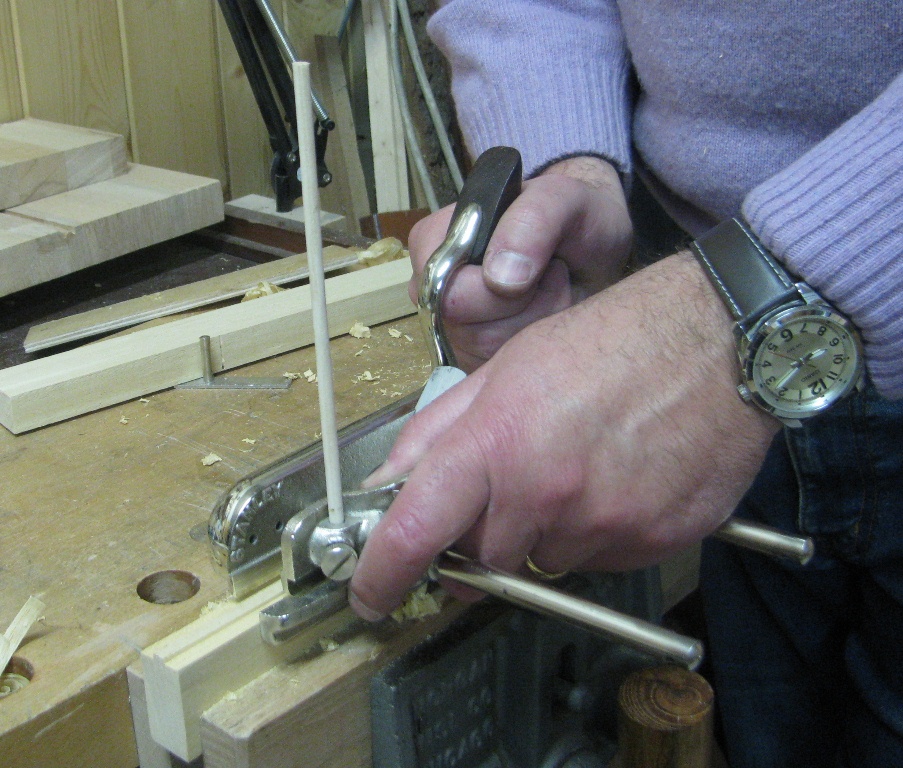

I have recently acquired the below Stanley 50, all the bits are there and it's in nearly new condition, even though it has to be over 40 years old. On a post somewhere else on this forum somebody posted that they had added a wooden strip to the fence of a similar plane. The question is how did they fix it.

I think the addition of a wooden strip would improve the use of this plough quite a bit. As the fence isn't quite as smooth as it could be.

I think the addition of a wooden strip would improve the use of this plough quite a bit. As the fence isn't quite as smooth as it could be.