katellwood

Established Member

wrought iron balusters maybe screw under the mortice for the iron

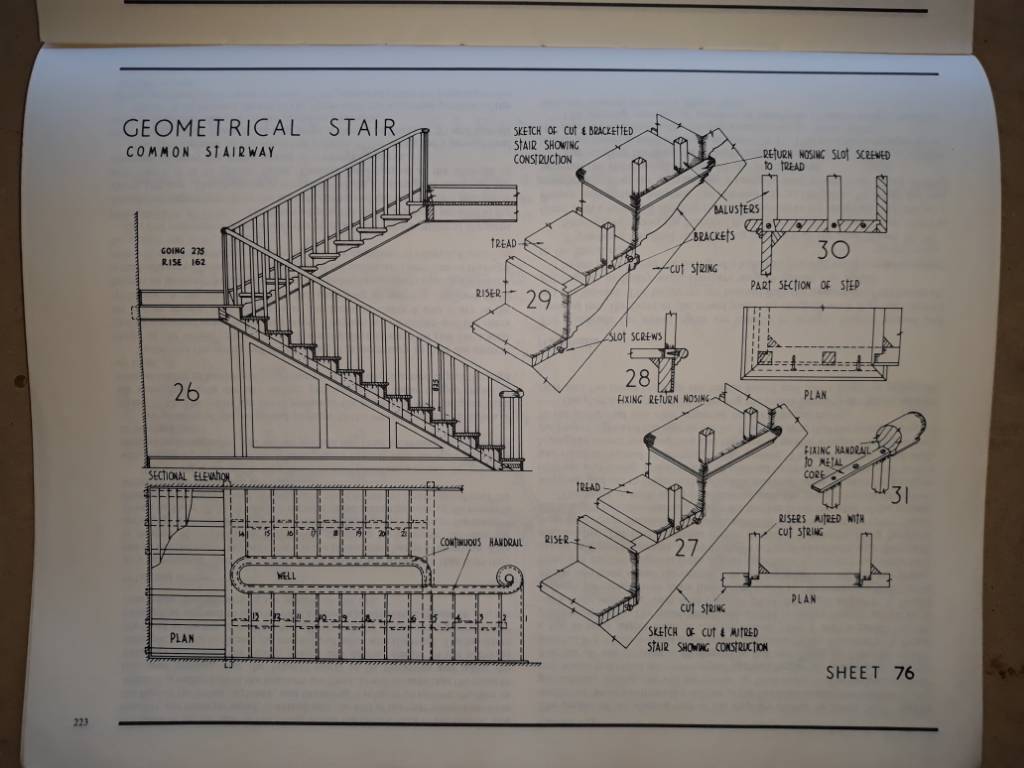

That picture looks like computer graphics so you won't see any useful clues.MikeG.":mtdgwpwh said:Right, the cut-string side of the stair, and the all-important junction between the riser and the string. I am planning on something very similar to this (albeit with some carving):

A couple of questions. How is the riser fixed to the cut string? I can see no pins or plugs, so I am guessing it is just glued (clamping will be fun!). That's a weak glue joint, being end grain to long grain.

Secondly, I have seen the mitred junction between the riser and the planted-on piece open up unpleasantly on older stairs. Because of the moulding under the tread, I don't want a planted on moulding over this junction. I am thinking about dovetailing this join, rather than a mitre. Does anyone have any thoughts on that? One of the drivers for that is that the the riser is likely to be much thicker than the planted-on detail, which makes the mitre a sod (in my workshop, at least). The main reason, though, is to produce a joint which doesn't open up over time, and I don't trust a butted mitre.

Yes is top notch. Mines 1955 3 volume with more detail. Still doesn't say much about cut strings (well out of fashion) so went to "Joinery& Carpentry"Jonathan S":75quoz92 said:Mike

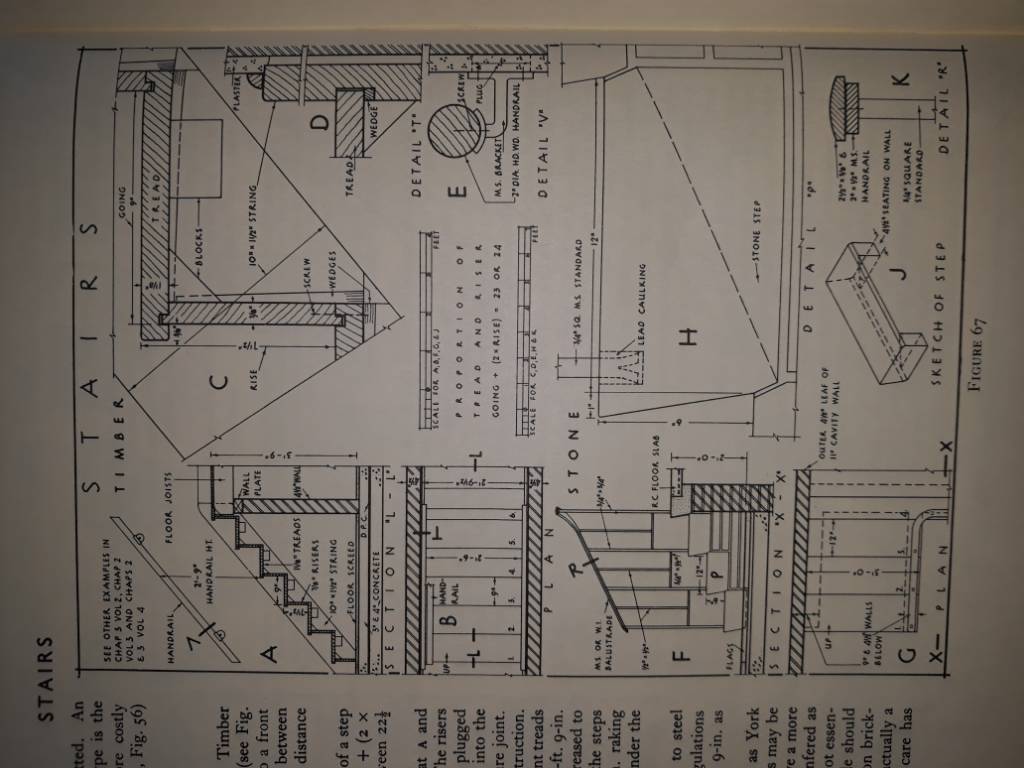

Here is a detail from McKay new edition 1968.....fantastic book! unfortunately only this on timber staircase construction.

What? You mean all that hedge stuff? :lol:MikeG.":366l5xrx said:I am sure that you are posting some terribly useful stuff Jacob, but you don't get to speak to me the way you did in the Brexit thread and then expect further interaction.

When I do stairs I glue the joint.MikeG.":2ggfsu9w said:If you are managing shrinkage across the tread at the back edge like this (as per a window board), does that imply that you don't fasten or glue the tread into the riser? I assume the answer to that is no, and that you glue and pin this junction, but I'm interested in your thoughts.

Glue everything. But not "tread into the riser" as that's the wrong way round anyway. Should be "riser into tread" and not glued at the lower edge. Something's got to give!ColeyS1":3az4j5s4 said:When I do stairs I glue the joint.MikeG.":3az4j5s4 said:If you are managing shrinkage across the tread at the back edge like this (as per a window board), does that imply that you don't fasten or glue the tread into the riser? I assume the answer to that is no, and that you glue and pin this junction, but I'm interested in your thoughts.

Sent from my SM-G960F using Tapatalk

MikeG.":3ar2wy81 said:What do you think of my idea of maybe dovetailing the bracket to the riser?

I think there's two different type of tread/riser discussions going on in this thread. Solid wood treads and risers, and mdf treads and risers.....I thinkJacob":z4gjmolu said:Glue everything. But not "tread into the riser" as that's the wrong way round anyway. Should be "riser into tread" and not glued at the lower edge. Something's got to give!ColeyS1":z4gjmolu said:When I do stairs I glue the joint.MikeG.":z4gjmolu said:If you are managing shrinkage across the tread at the back edge like this (as per a window board), does that imply that you don't fasten or glue the tread into the riser? I assume the answer to that is no, and that you glue and pin this junction, but I'm interested in your thoughts.

Sent from my SM-G960F using Tapatalk

Enter your email address to join: