digitalbot

Established Member

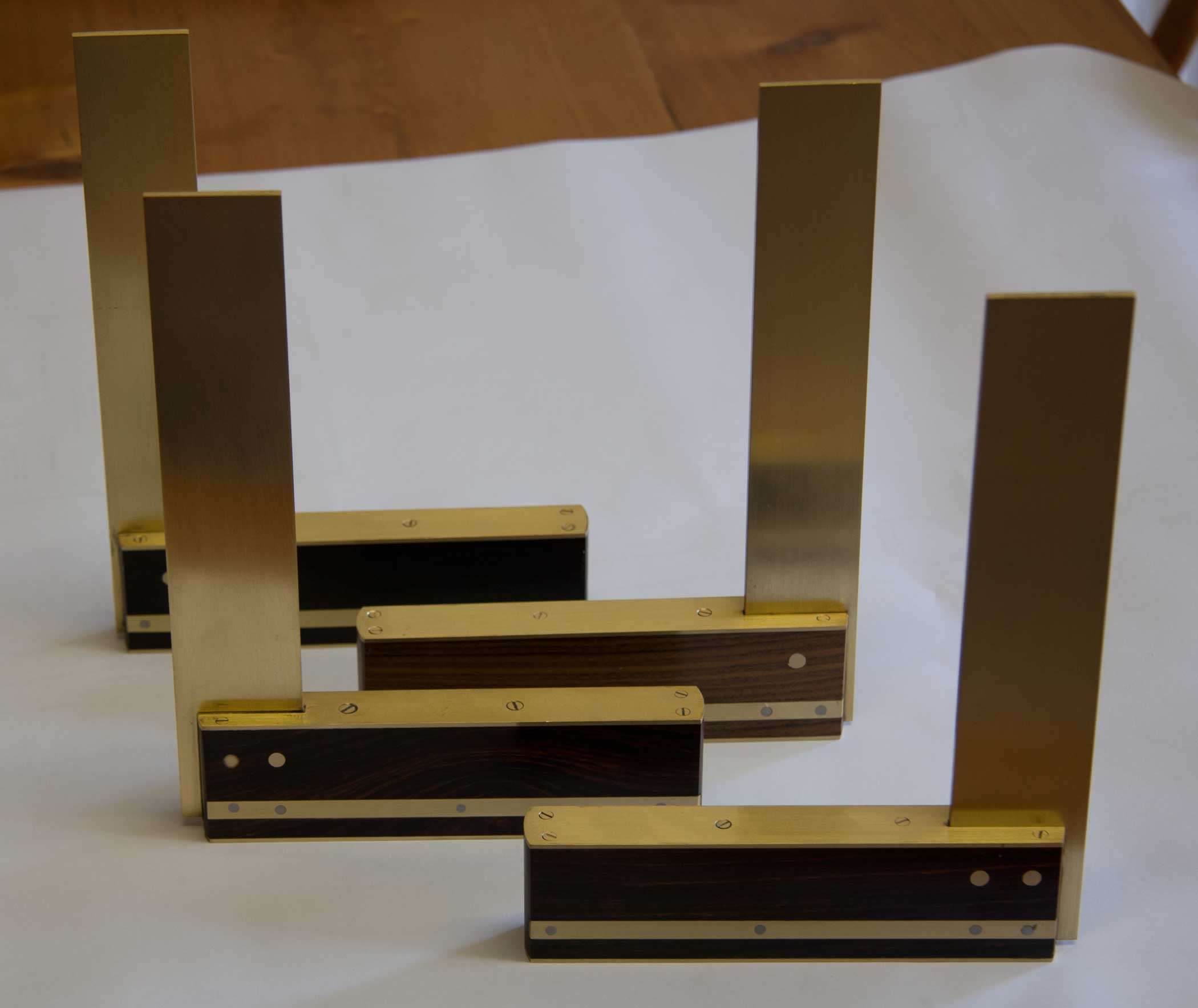

Has anyone any experience of repairing these things?

As you can see from the photo, the brass face has come away at the top and I can't think how I would re-attach it and make it useable again ( the metal thing in the gap is a fat feeler gauge ).

How is the brass face attached to the wooden stock? Does anyone know?

I can't see how I would get a drill bit in there and keep it parallel and stop it veering off into the steel.

And I am reluctant to try and prise it all off for fear of ruining it completely.

All suggestions welcome.

As you can see from the photo, the brass face has come away at the top and I can't think how I would re-attach it and make it useable again ( the metal thing in the gap is a fat feeler gauge ).

How is the brass face attached to the wooden stock? Does anyone know?

I can't see how I would get a drill bit in there and keep it parallel and stop it veering off into the steel.

And I am reluctant to try and prise it all off for fear of ruining it completely.

All suggestions welcome.