frosties

Established Member

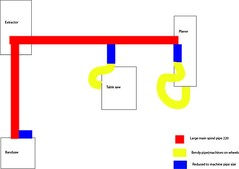

Hi there. I've just bought the following items and need to get the spiral ducting sorted out

Bandsaw/resaw

http://www.startrite.co.uk/index.php?se ... and+Resaws

Planer thicknesser

http://www.startrite.co.uk/index.php?se ... hicknesser

Extractor

http://www.startrite.co.uk/index.php?se ... Extraction

The hose outlet for the extractor is a 220mm. I'm trying to work out when the best time to use a reducer?? do I reduce by the extractor? do I have a reducer just before the machine?

Heres what I propose to do

I appreciate any advise before I splash out on ducting blast gates and angles. I'm not too sure if the unit has enough oomph

Print by frostie's, on Flickr

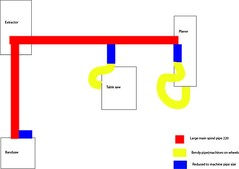

Bandsaw/resaw

http://www.startrite.co.uk/index.php?se ... and+Resaws

Planer thicknesser

http://www.startrite.co.uk/index.php?se ... hicknesser

Extractor

http://www.startrite.co.uk/index.php?se ... Extraction

The hose outlet for the extractor is a 220mm. I'm trying to work out when the best time to use a reducer?? do I reduce by the extractor? do I have a reducer just before the machine?

Heres what I propose to do

I appreciate any advise before I splash out on ducting blast gates and angles. I'm not too sure if the unit has enough oomph

Print by frostie's, on Flickr