Froggy

Established Member

Hi All,

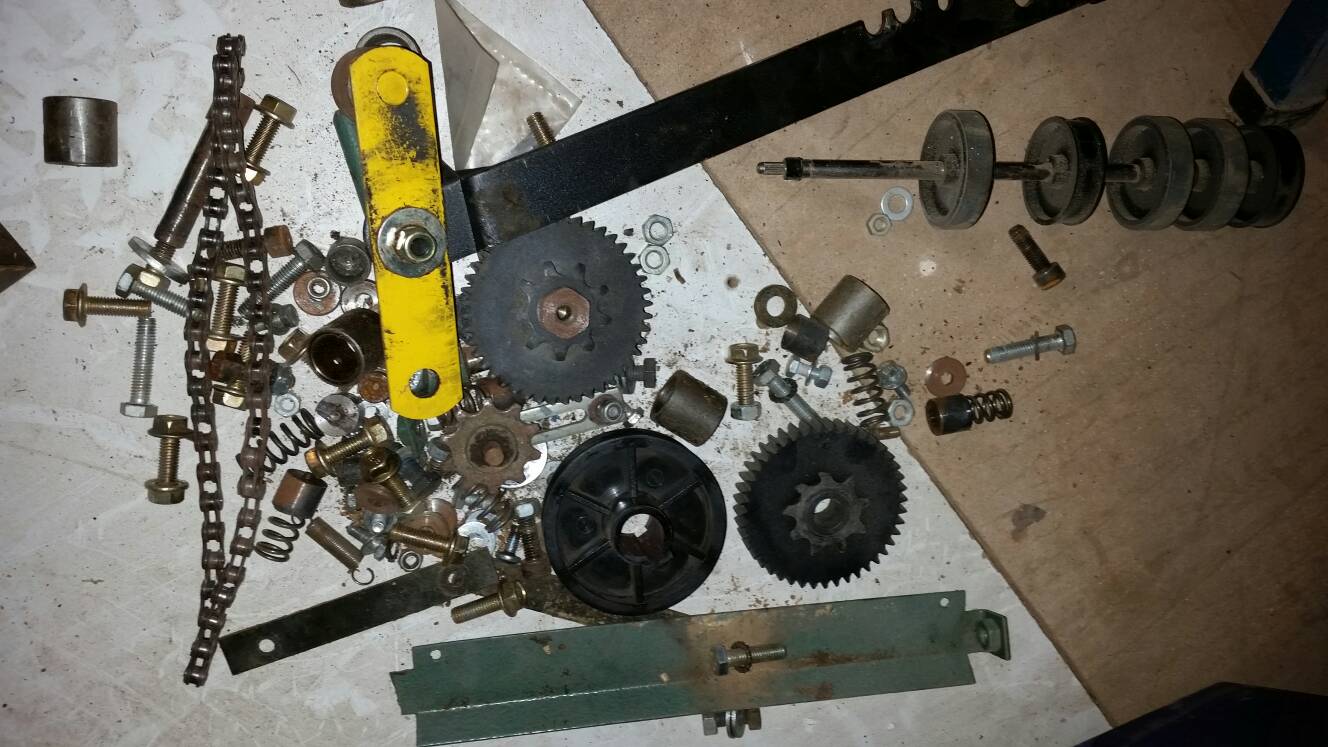

I'm looking for a this pulley http://www.probois-machinoutils.com/en/ ... hings.html for my Kity PT. I can't get one anywhere. The company who are advertising this say they can no longer supply them either. Does anyone know where I might be able to get one please? I know the whole Kity - Scheppach story and don't hold out much hope for a new one, but I thought one of you might have a broken down old Kity pt at the back of the workshop with this pulley attached. :roll: I can always hope :lol:

Cheers, Froggy.

I'm looking for a this pulley http://www.probois-machinoutils.com/en/ ... hings.html for my Kity PT. I can't get one anywhere. The company who are advertising this say they can no longer supply them either. Does anyone know where I might be able to get one please? I know the whole Kity - Scheppach story and don't hold out much hope for a new one, but I thought one of you might have a broken down old Kity pt at the back of the workshop with this pulley attached. :roll: I can always hope :lol:

Cheers, Froggy.