nev

Established Member

I have come to the conclusion that the biggest hurdle i have in turning is getting a constantly and correctly shaped edge when sharpening. In light of this my next WS purchase will be a sharpening jig.

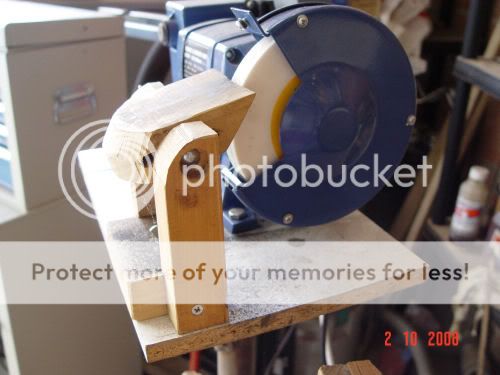

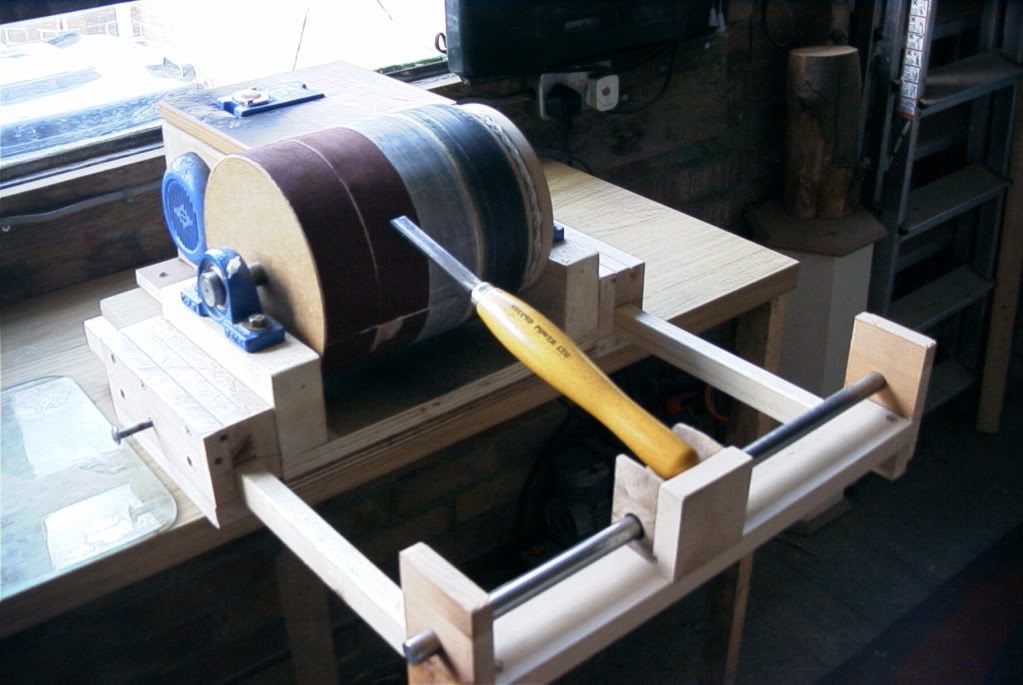

Not being made of money I am afraid the proedges and tormeks are outa my league but the bench grinder 'conversion' kits I could probably stretch to.

but the bench grinder 'conversion' kits I could probably stretch to.

http://www.tormek.com/en/accessories/bgm100/index.php

http://www.toolpost.co.uk/pages/Grindin ... l#SorbyJig

My main issue is with the spindle (generally too pointy) and bowl (uneven) gouges. I have an RP 6" grinder.

My choices seem to be between the Sorby 447 deluxe (plus a few minor jiggy bits) and the tormek kit (125 quid), or the likes of the wolverine/ storme/ trugrind/ dakota type jigs. (£less)

My question to the more experienced of you out there is this... does anyone have any experience of more than one of the above? moved from one type to another? swear by or avoid like the plague etc.

I am leaning towards the tormek but before i splash out, any reasons not too? :?

Not being made of money I am afraid the proedges and tormeks are outa my league

http://www.tormek.com/en/accessories/bgm100/index.php

http://www.toolpost.co.uk/pages/Grindin ... l#SorbyJig

My main issue is with the spindle (generally too pointy) and bowl (uneven) gouges. I have an RP 6" grinder.

My choices seem to be between the Sorby 447 deluxe (plus a few minor jiggy bits) and the tormek kit (125 quid), or the likes of the wolverine/ storme/ trugrind/ dakota type jigs. (£less)

My question to the more experienced of you out there is this... does anyone have any experience of more than one of the above? moved from one type to another? swear by or avoid like the plague etc.

I am leaning towards the tormek but before i splash out, any reasons not too? :?