Paul.J

Established Member

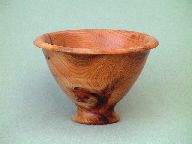

Very nice Chas

I like the detail on the rim again.Great grain pattern too.

I nearly bought an Elm blank last week,but all the pieces he had looked a bit too plain,unlike the pieces you have been doing

I like the detail on the rim again.Great grain pattern too.

I nearly bought an Elm blank last week,but all the pieces he had looked a bit too plain,unlike the pieces you have been doing