garethharvey

Established Member

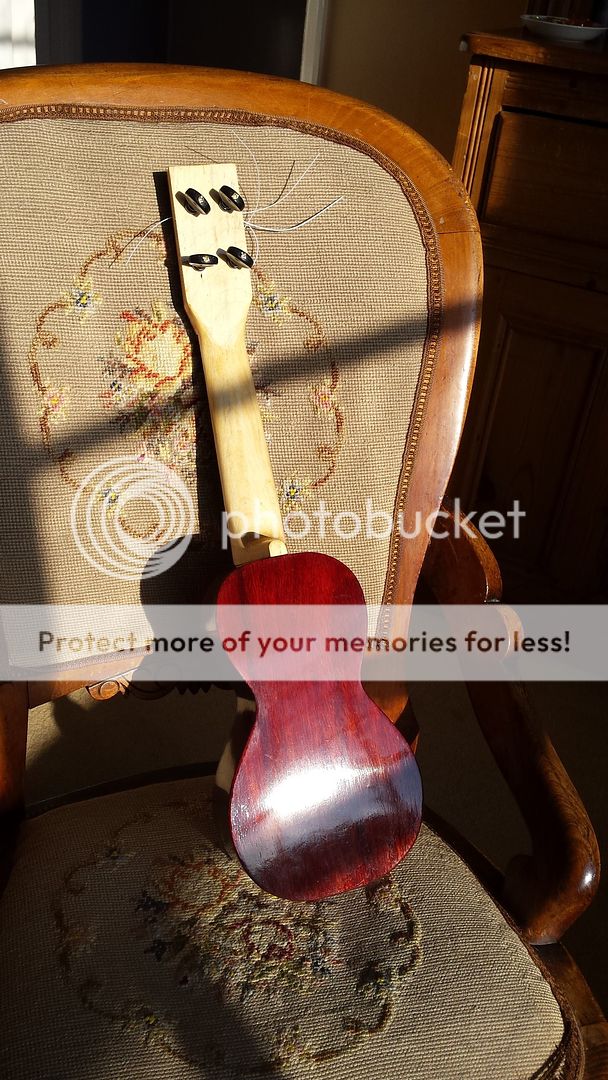

Just about to finish some Padauk with Shellac. Only issue is, I have never used Shellac and have no idea where to start.

I found this post about Padauk and this seems to be the best option: http://www.woodworkerssource.com/bl...sh-african-padauk-wood-to-preserve-the-color/

Any idea where I start, what I buy?

I found this post about Padauk and this seems to be the best option: http://www.woodworkerssource.com/bl...sh-african-padauk-wood-to-preserve-the-color/

Any idea where I start, what I buy?