garywayne

Established Member

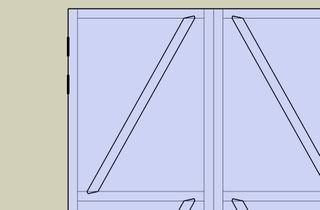

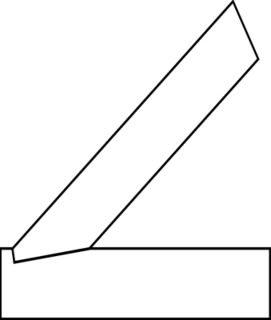

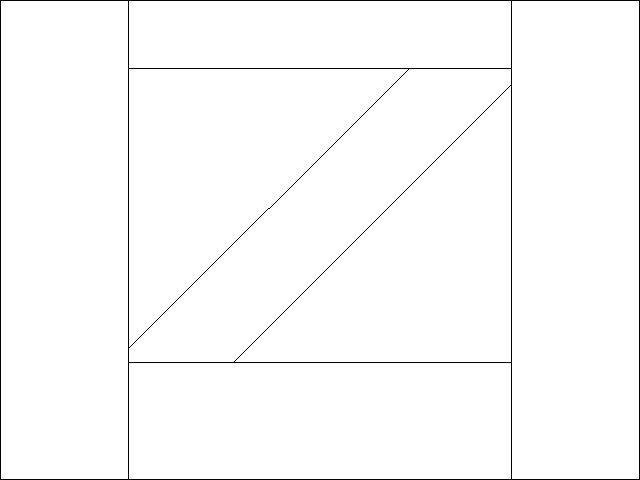

My shed is going to be insulated. Should I build the doors the same way as the walls?

The hole in the shed front wall is 5' wide, 6'6" high, (1530mm wide, 1980mm high).

How would you build two 2'6" wide doors? A picture of the design would be most helpful.

Thanks for your help.

The hole in the shed front wall is 5' wide, 6'6" high, (1530mm wide, 1980mm high).

How would you build two 2'6" wide doors? A picture of the design would be most helpful.

Thanks for your help.