musomaniac

Established Member

with me being still a complete novice to turning , my tools are still all sharp apart from one i've been using for the pen blanks , and thats a skew chisel i think

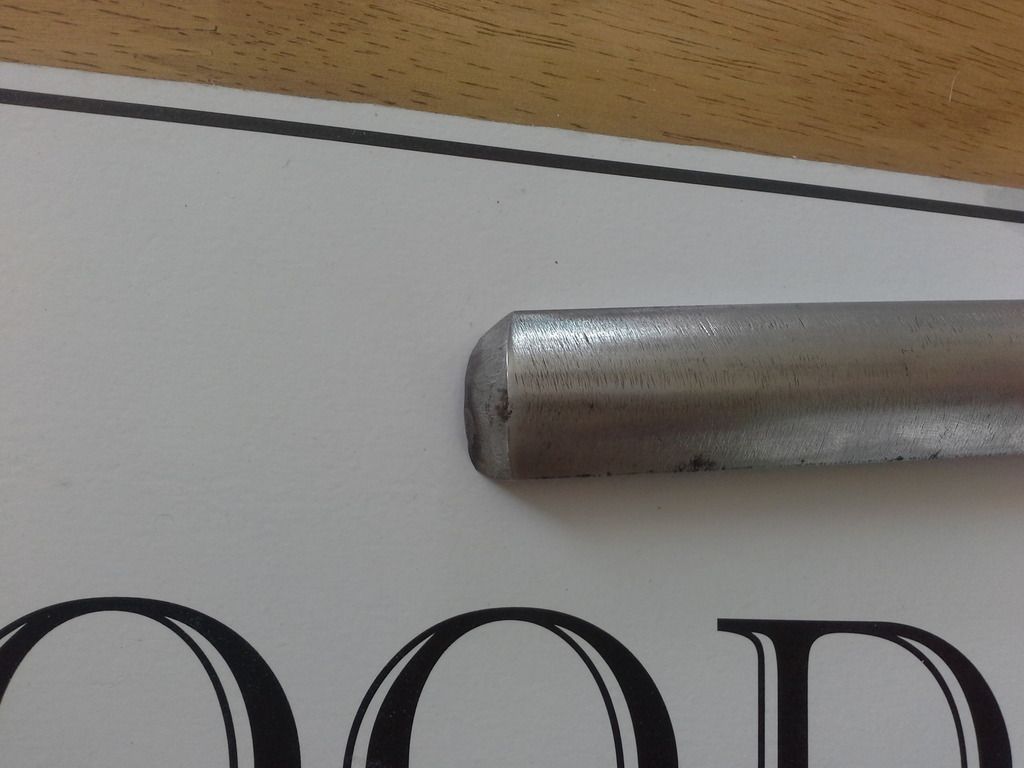

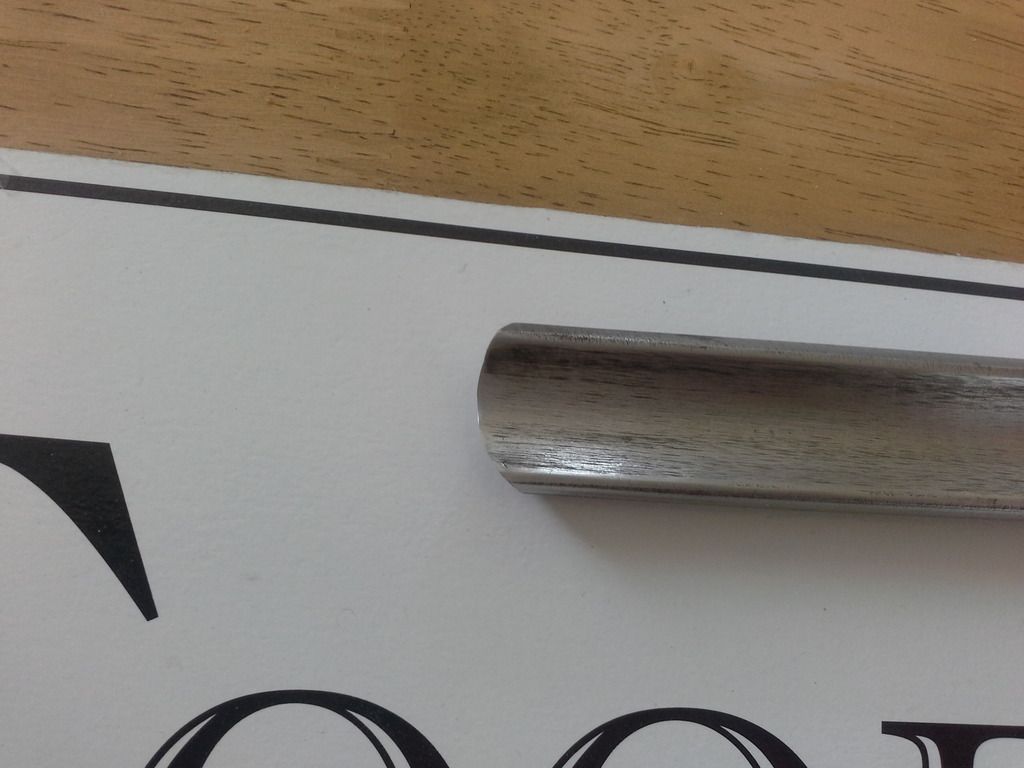

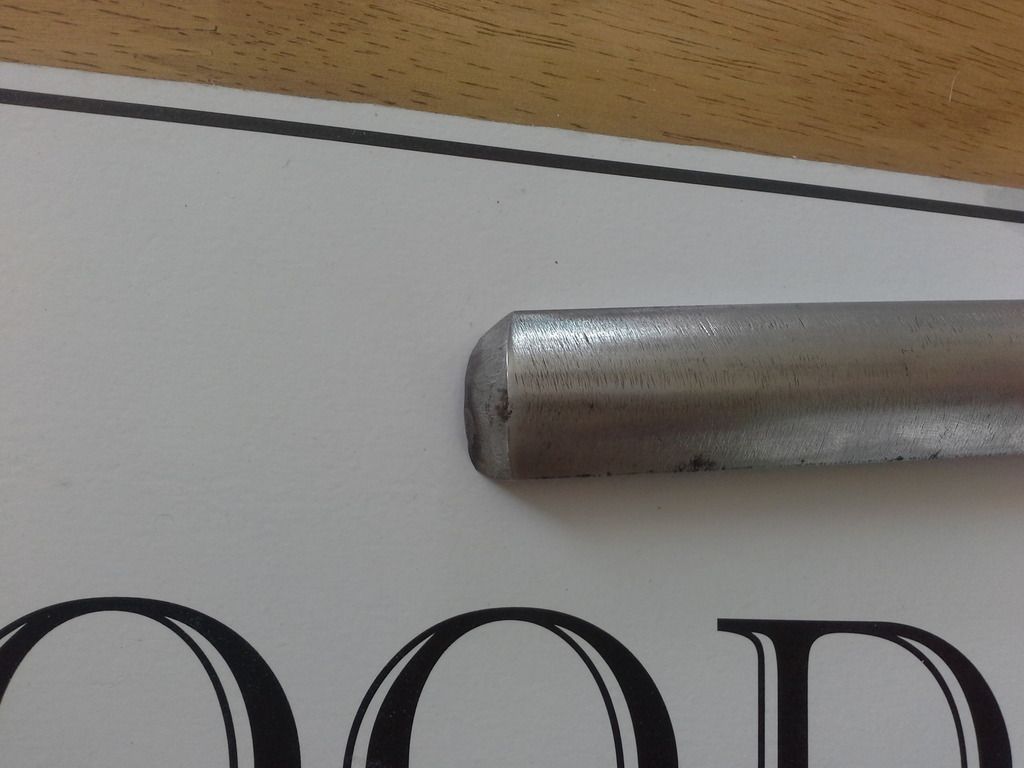

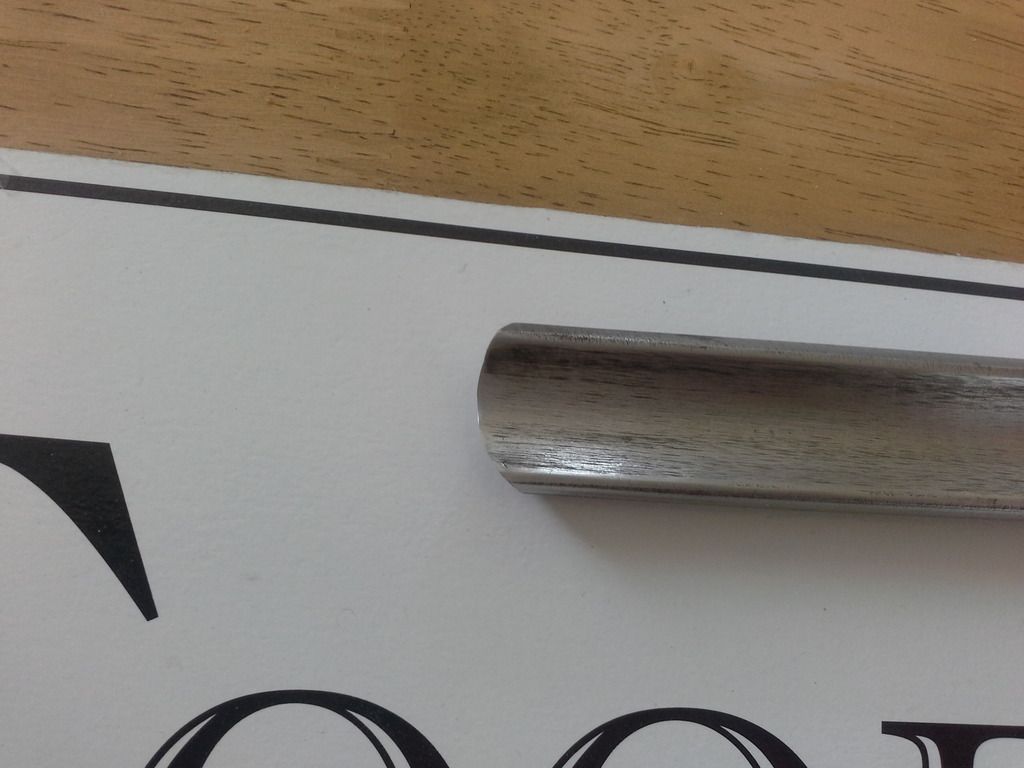

i also bought this robert sorby bowl gouge ?? for a tenner ........but as you can see in the photos its needing sharpening , i have a bench grinder , and a belt disc sander , which one would be the best for sharpening , and what jigs would i require building or purchasing

i also bought this robert sorby bowl gouge ?? for a tenner ........but as you can see in the photos its needing sharpening , i have a bench grinder , and a belt disc sander , which one would be the best for sharpening , and what jigs would i require building or purchasing