I don’t quite get what you’re saying here. How are you suggesting working the back? You presumably are not suggesting working the whole back, keeping the two flat faces parallel, to remove the wear (which would seem a bit daft). Yet you also seem to be dismissing the ‘ruler trick’ as ineffective?

In bullet points - if you want to keep using the ruler trick:

* ignore that it can leave a little bit of wear at the edge. If you didn't mind it when you couldn't see it, then don't worry. Better to leave a little wear than chase the ruler trick stripe wider

* this is on a smoothing plane with a cap iron set around 1 hundredth of an inch. I didn't look at this on a plane with the cap set far off, but the wear may be less deep and more rounded out rather than in without a cap - it's not very productive to use a smoother without the cap iron

* In my opinion, the solution with the cap iron used is probably as simple as increasing the rule thickness. I have a 0.5mm rule that I started using early on when I first started sharpening (learned from DC's video on plane sharpening). I'd be willing to bet 1mm instead of 0.5mm would solve the problem

About the ruler trick vs flat surface

* the idea of removing metal on the entire back is a logical trap. Metal bends, even under finger pressure. when you sharpen an iron or chisel, you apply finger pressure at the tip or on one side or the other. Wherever you apply pressure, that's where the back will be honed. If you apply pressure in the middle of an iron, the middle will become well burnished and the edge won't get much honing. If you forgo the rulertrick, think of the term directed pressure

* most people use a very fine stone with the ruler trick (if you don't, you'll get a wire edge. If you're working the back, you can use a coarser stone with directed pressure to speed things up (fingers at the tip, first heavy pressure for 10 seconds, then lighter)

* The first rule of sharpening is completing the job (at least that's my opinion). All of the potential in the world doesn't matter if it comes up short at the tip.

OK, so here's a picture illustration of pressure. Washita, flat back:

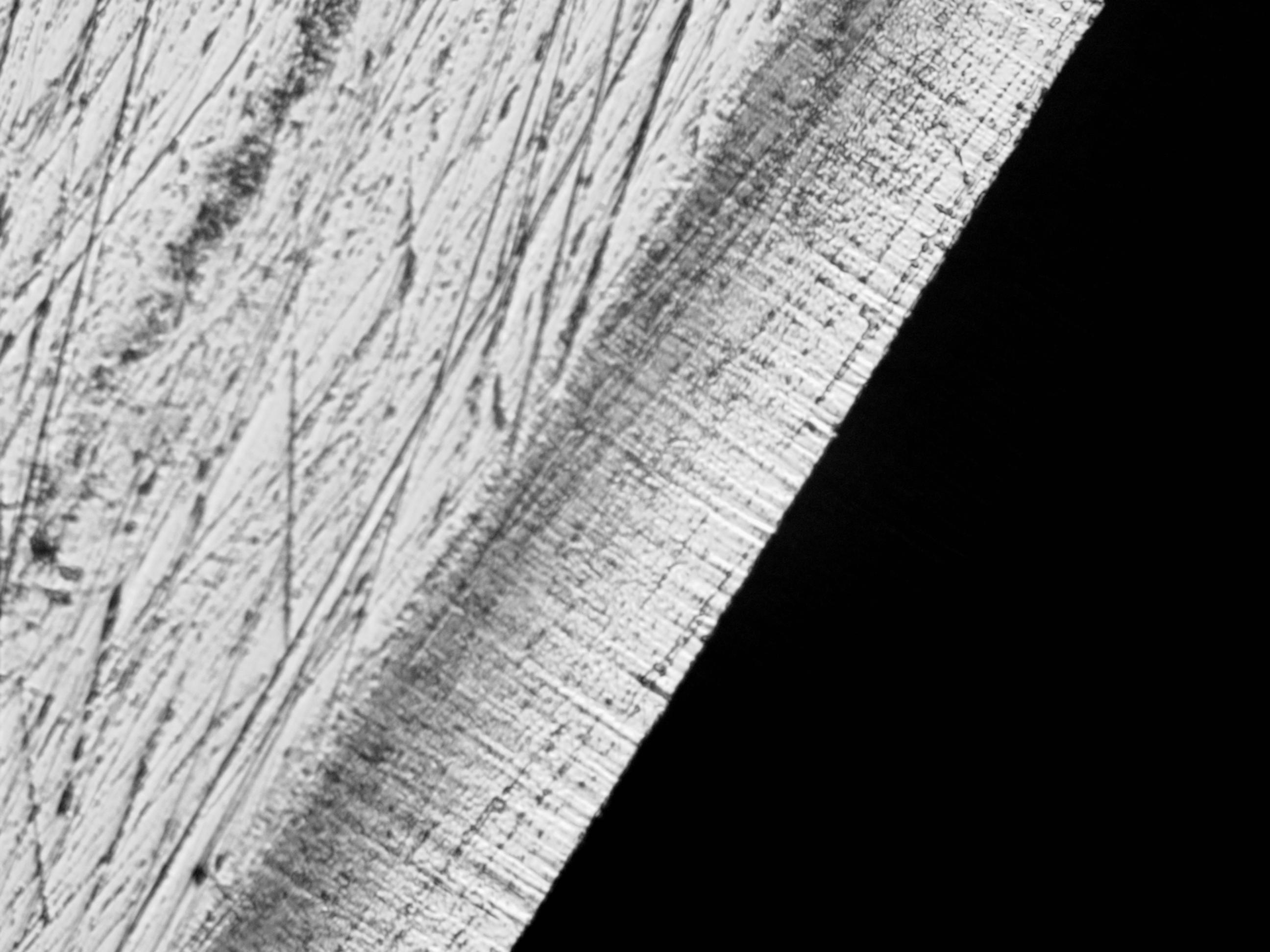

Heavy pressure for ten seconds with finger pressure at the tip (notice, the wear stripe is gone, but the surface looks pretty coarse):

Same stone, 10 more seconds then with light pressure:

20 seconds total. How long does it take to do the ruler trick? I don't know - you can do it quickly and remove a burr, but if you're using a fine stone and doing appreciable work to remove wear, it'll take 20 seconds.

In the case of this iron, I use a grinder and the washita on the bevel and back, and then buff the bevel side with a buffer (which is why the edge is so uniform).

Recall this vs. the shapton 12000 without a buffer:

Am I losing anything in sharpness by doing the above and not using the ruler trick?

I don't think so. compare the uniformity of the initial edge.

These are the kinds of things you'll do if you sharpen several things a day or maybe several a week, but if you don't do that, then maybe it doesn't make sense to speed up the process.

I've seen pictures of jacob's edges. They aren't close to the quality of the edges David Charlesworth produces in his instructional video.